The Future of Orthopedics: 3D-Printed Synthetic Bone Graft Scaffolds for Enhanced Healing

This article provides a comprehensive overview of 3D printing technologies for synthetic bone graft scaffolds, targeting researchers and biomedical professionals.

The Future of Orthopedics: 3D-Printed Synthetic Bone Graft Scaffolds for Enhanced Healing

Abstract

This article provides a comprehensive overview of 3D printing technologies for synthetic bone graft scaffolds, targeting researchers and biomedical professionals. It explores the fundamental materials like bioceramics and polymers, details advanced manufacturing methodologies such as digital light processing and extrusion-based bioprinting, and addresses critical challenges in scaffold design and mechanical properties. The content further examines rigorous validation techniques, including in vitro bioactivity assays and comparative analyses with traditional autografts and allografts. The synthesis aims to bridge current research with future clinical applications in personalized bone regeneration.

From Materials to Models: The Science Behind 3D-Printed Bone Scaffolds

Application Notes

This document provides application notes and experimental protocols for core biomaterials used in the 3D printing of synthetic bone graft scaffolds. These scaffolds are critical for bone tissue engineering, addressing limitations of autografts and allografts.

Hydroxyapatite (HA)

Hydroxyapatite (Ca₁₀(PO₄)₆(OH)₂) is a calcium phosphate ceramic that mimics the mineral phase of natural bone (~70 wt%). Its key properties include excellent osteoconductivity, bioactivity (forming a direct bond with bone), and slow in vivo degradation. However, its brittleness and slow degradation rate necessitate composite formation.

Primary Applications in 3D Printing:

- Binder Jetting: HA powder is bound layer-by-layer using a polymeric binder.

- Direct Ink Writing (DIW): HA is incorporated into a shear-thinning hydrogel or paste for extrusion.

- Selective Laser Sintering (SLS): HA-polymer composite powders are fused using a laser.

- Stereolithography (SLA): HA is suspended in a photocurable resin.

Tricalcium Phosphate (TCP)

TCP exists in two crystallographic forms: α-TCP and β-TCP. β-TCP (Ca₃(PO₄)₂) is more commonly used due to its greater stability and controlled biodegradability (6-18 months). It is more soluble than HA and actively participates in bone remodeling, being resorbed by osteoclasts and replaced by new bone.

Primary Applications in 3D Printing:

- Often used in biphasic calcium phosphate (BCP) composites with HA to tailor degradation rates.

- Extruded as a paste with biodegradable polymers.

- Processed via SLS with polycaprolactone (PCL) to create strong, resorbable scaffolds.

Bioactive Polymers

This class includes natural and synthetic polymers that facilitate bioactivity and provide tailored mechanical/ degradation properties.

- Natural: Collagen, chitosan, alginate, hyaluronic acid. Provide cell-recognition sites but have variable properties.

- Synthetic: Polycaprolactone (PCL), polylactic acid (PLA), poly(lactic-co-glycolic acid) (PLGA). Offer predictable mechanical strength and degradation kinetics (weeks to years).

Primary Applications in 3D Printing:

- PCL/PLA/PLGA: Widely used in Fused Deposition Modeling (FDM) and SLS for structural support.

- Gelatin/Alginate: Used in DIW and bioprinting at low temperatures to encapsulate cells.

- Photopolymers (e.g., PEGDA): Used in SLA/DLP, often combined with HA/TCP particles to create bioactive, precise scaffolds.

Quantitative Comparison of Core Biomaterial Properties

Table 1: Key Properties of Core Biomaterials for 3D-Printed Bone Scaffolds

| Property | Hydroxyapatite (HA) | β-Tricalcium Phosphate (β-TCP) | Polycaprolactone (PCL) | Polylactic Acid (PLA) |

|---|---|---|---|---|

| Chemical Formula | Ca₁₀(PO₄)₆(OH)₂ | Ca₃(PO₄)₂ | (C₆H₁₀O₂)ₙ | (C₃H₄O₂)ₙ |

| Degradation Rate | Very Slow (>2-3 years) | Moderate (6-18 months) | Slow (2-4 years) | Moderate (months - 2 years) |

| Compressive Strength (MPa) | 30-300 (Dense) | 20-100 (Dense) | 10-50 | 45-70 |

| Young's Modulus (GPa) | 70-120 | 30-100 | 0.2-0.5 | 3-4 |

| Osteoconductivity | Excellent | Excellent | Poor (unless composite) | Poor (unless composite) |

| Primary 3D Printing Use | Binder Jetting, SLA, DIW | DIW, SLS (with polymer) | FDM, SLS | FDM |

| Key Advantage | High bioactivity & bonding | Biodegradable, remodeled | Ductile, long-term support | Good strength, FDA-approved |

Table 2: Typical Composition & Performance of 3D-Printed Composite Scaffolds

| Composite Formulation | 3D Printing Method | Porosity (%) | Compressive Strength (MPa) | Key Outcome (In Vivo) |

|---|---|---|---|---|

| HA/Collagen Paste | Direct Ink Writing | 60-70 | 2-10 | Enhanced osteogenesis vs. pure HA. |

| β-TCP/PCL (60/40 wt%) | Selective Laser Sintering | 50-60 | 8-15 | Balanced degradation & bone formation at 12 weeks. |

| HA/PLGA Microspheres | Fused Deposition Modeling | 40-50 | 20-40 | Sustained drug release, good bone ingrowth. |

| PEGDA-HA (20 wt%) | Stereolithography | 70-80 | 5-20 | High precision, excellent cell seeding. |

Experimental Protocols

Protocol 1: Direct Ink Writing (DIW) of a β-TCP/Alginate Composite Scaffold

Aim: To fabricate a biodegradable, osteoconductive scaffold with defined architecture.

Materials:

- β-TCP powder (particle size < 10 µm)

- Sodium alginate powder

- Calcium chloride (CaCl₂) dihydrate

- Deionized water

- DIW 3D printer with pneumatic extrusion system and nozzle (250-400 µm diameter)

- CAD model of scaffold (e.g., 0/90° lattice)

Procedure:

- Ink Preparation: Prepare a 4% (w/v) sodium alginate solution in deionized water. Mix β-TCP powder into the alginate solution at a 40% (w/v) loading ratio. Stir vigorously (2 hrs) and then degas under vacuum to remove air bubbles.

- Printer Setup: Load the ink into a syringe barrel. Attach the nozzle. Set pneumatic pressure (20-35 psi) and print speed (5-10 mm/s) via printer software.

- Crosslinking Bath Preparation: Prepare a 2% (w/v) CaCl₂ solution in a Petri dish.

- Printing: Initiate printing layer-by-layer into the CaCl₂ bath for immediate ionic crosslinking of alginate.

- Post-Processing: After printing, immerse the scaffold in fresh CaCl₂ solution for 10 minutes for complete crosslinking. Rinse gently with DI water.

- Characterization: Analyze scaffold morphology via SEM, measure compressive strength, and conduct in vitro degradation in simulated body fluid (SBF).

Protocol 2:In VitroBioactivity Assessment in Simulated Body Fluid (SBF)

Aim: To evaluate the apatite-forming ability (bioactivity) of a 3D-printed scaffold.

Materials:

- 3D-printed scaffold samples (HA, TCP, or composite)

- Reagents to prepare SBF (NaCl, NaHCO₃, KCl, K₂HPO₄·3H₂O, MgCl₂·6H₂O, CaCl₂, Na₂SO₄, Tris buffer)

- Incubator at 36.5°C

- Scanning Electron Microscope (SEM) with EDS

- X-ray Diffractometer (XRD)

Procedure:

- SBF Preparation: Prepare SBF according to Kokubo's protocol, ensuring ion concentrations equal to human blood plasma. Adjust pH to 7.40 at 36.5°C using Tris buffer and HCl.

- Immersion: Place each sterile scaffold sample in a separate container with a volume of SBF 10x the sample's surface area. Incubate at 36.5°C for periods of 1, 7, and 14 days. Replace SBF every 48 hours.

- Sample Retrieval: At each time point, remove samples, rinse gently with DI water, and dry at room temperature.

- Analysis:

- SEM/EDS: Image the surface morphology. Look for a cauliflower-like apatite layer. Perform EDS to confirm Ca/P ratio (~1.67).

- XRD: Identify crystalline phases. Look for characteristic hydroxyapatite peaks (e.g., at 2θ ≈ 26° and 32°) emerging on the material surface.

- Interpretation: Formation of a bone-like apatite layer indicates high bioactivity, predicting direct bonding with bone in vivo.

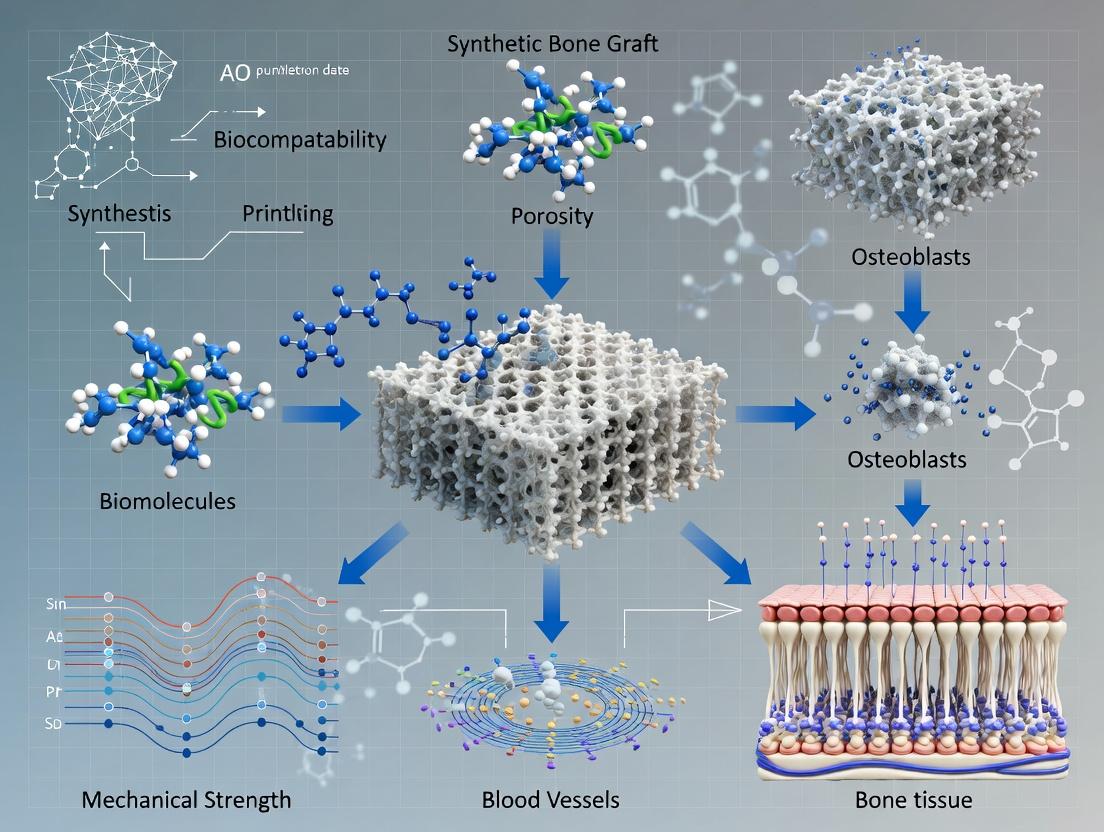

Visualizations

Title: Thesis Workflow for 3D Printed Bone Scaffolds

Title: Osteogenic Signaling Pathway on Bioactive Scaffolds

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for 3D Printing Bone Scaffold Research

| Item / Reagent | Function / Application | Key Consideration |

|---|---|---|

| β-TCP Powder (< 50 µm) | Primary osteoconductive ceramic for DIW or SLS inks. | Purity (>98%) and particle size distribution affect printability & bioactivity. |

| Medical Grade PCL Pellet | Synthetic polymer for FDM or SLS; provides structural integrity. | Molecular weight (e.g., 50-80 kDa) dictates melt viscosity & degradation rate. |

| Sodium Alginate (High G) | Natural polymer for DIW; provides shear-thinning and ionic crosslinking. | Guluronic acid (G) content determines gel strength and stability. |

| Polyethylene Glycol Diacrylate (PEGDA, MW 700) | Photocurable resin for SLA; can be blended with ceramic particles. | Degree of functionalization and molecular weight control crosslink density. |

| Simulated Body Fluid (SBF) Kit | Standardized solution for in vitro bioactivity (apatite formation) testing. | Must follow Kokubo protocol precisely for reproducible results. |

| Cell Culture Media (α-MEM) | For in vitro osteoblast seeding and proliferation studies on scaffolds. | Supplements (FBS, ascorbic acid, β-glycerophosphate) are required for differentiation. |

| AlamarBlue or MTS Assay Kit | Colorimetric assay for quantifying cell viability and proliferation on scaffolds. | Requires standard curve and careful removal of unreacted dye from porous scaffolds. |

| Osteogenic Antibody Panel (Runx2, OPN, OCN) | For immunofluorescence staining to confirm osteogenic differentiation of cells. | Requires optimized permeabilization and blocking for 3D scaffold structures. |

Within the broader thesis on 3D printing of synthetic bone graft scaffolds, the dual rationale of achieving patient-specific geometry and controlled porosity is paramount. Patient-specific geometry, derived from clinical CT/MRI scans, ensures an anatomical fit and mechanical stability at the implant site, enhancing osteointegration. Controlled porosity, dictated by scaffold design and printing parameters, directly influences critical biological outcomes: pore size, interconnectivity, and strut architecture govern vascular ingrowth, nutrient diffusion, and stem cell differentiation. This synergy addresses the limitations of off-the-shelf grafts by creating biomimetic, bioactive constructs that can be further functionalized with drugs or growth factors for enhanced bone regeneration.

Key Experimental Data & Comparative Analysis

Table 1: Influence of 3D Printing Parameters on Scaffold Porosity and Mechanical Properties

| Printing Technology | Material | Pore Size (µm) | Porosity (%) | Compressive Modulus (MPa) | Key Biological Outcome (e.g., Cell Viability, Osteogenesis) |

|---|---|---|---|---|---|

| Extrusion-based | PCL/β-TCP Composite | 350 - 500 | 60 - 70 | 40 - 120 | Enhanced osteogenic differentiation of hMSCs in vitro |

| SLA/DLP | PEGDA/Hydroxyapatite | 200 - 400 | 50 - 65 | 150 - 300 | High cell seeding efficiency (>85%) and neovascularization |

| SLS | PCL | 400 - 700 | 70 - 80 | 10 - 50 | Favorable for rapid vascular invasion in vivo |

| Inkjet (Binder Jetting) | Calcium Sulfate/Phosphate | 100 - 300 | 40 - 55 | 5 - 20 | Excellent biodegradation matching new bone formation |

Table 2: Clinical & Pre-Clinical Outcomes of Patient-Specific 3D-Printed Scaffolds

| Anatomical Site | Study Type | Follow-up Period | Key Metric | Result with 3D-Printed Scaffold vs. Control |

|---|---|---|---|---|

| Craniofacial Defect | Pre-clinical (Ovine) | 6 months | Bone Volume/Tissue Volume (BV/TV) (%) | 58.2 ± 5.1 vs. 32.4 ± 4.8 (Allograft) |

| Mandibular Reconstruction | Clinical Case Series | 12 months | Implant Stability Quotient (ISQ) | 72.5 ± 3.2 (indicating successful load-bearing integration) |

| Tibial Segmental Defect | Pre-clinical (Rabbit) | 8 weeks | Angiogenesis (Vessels per mm²) | 12.3 ± 1.5 vs. 6.8 ± 1.2 (Porous Commercial Implant) |

| Spinal Fusion | In vitro Model | N/A | ALP Activity (nmol/min/µg protein) | 2.8x increase on graded porosity scaffold vs. uniform |

Detailed Experimental Protocols

Protocol 3.1: Design and Fabrication of a Patient-Specific, Graded Porosity Scaffold

Objective: To fabricate a biodegradable composite scaffold with anatomically accurate geometry and regionally varied porosity to direct cell behavior.

Materials:

- Medical CT scan data (DICOM format)

- CAD/Scaffold design software (e.g., 3D Slicer, Meshmixer, nTopology)

- Biopolymer (e.g., PLLA, PCL)

- Ceramic powder (e.g., nano-hydroxyapatite, β-TCP)

- Solvent (e.g., Chloroform for PCL)

- Extrusion-based 3D Bioprinter (e.g., Allevi 3, BIO X) with heated syringe

- Fume hood, vacuum desiccator.

Methodology:

- Image Segmentation & 3D Modeling: Import DICOM files into 3D Slicer. Segment the bone defect region using thresholding tools. Export as an STL file.

- Scaffold Design with Graded Porosity: Import the defect STL into scaffold design software. Design a conforming scaffold with a core-shell architecture:

- Core: Define a gyroid lattice with pore size 600µm (targeting vascular invasion).

- Shell/Outer Layer: Define a smaller pore size (300µm) with higher strut density for improved mechanical strength and surface area for cell attachment.

- Export the final design as a G-code file.

- Ink Preparation: Prepare a composite ink of PCL (15% w/v) and 20% w/w β-TCP in chloroform. Stir for 12 hours. Pour into a glass dish and evaporate solvent in a fume hood. Re-melt and load into printer cartridge.

- Printing: Set printer parameters: Nozzle Diameter: 250µm, Nozzle Temp: 85°C, Bed Temp: 25°C, Printing Pressure: 550 kPa, Layer Height: 150µm. Execute G-code.

- Post-Processing: Place printed scaffold in a vacuum desiccator for 48h to remove residual solvent. Sterilize using ethylene oxide or ethanol immersion for in vitro/vivo studies.

Protocol 3.2: In Vitro Evaluation of Osteogenic Response to Controlled Porosity

Objective: To assess human Mesenchymal Stem Cell (hMSC) adhesion, proliferation, and osteogenic differentiation on scaffolds with defined pore architectures.

Materials:

- hMSCs (e.g., Lonza)

- Osteogenic medium (DMEM, FBS, dexamethasone, β-glycerophosphate, ascorbic acid)

- Cell viability assay kit (e.g., AlamarBlue, MTT)

- Fixative (4% PFA), SEM preparation reagents

- qPCR reagents for osteogenic markers (RUNX2, OPN, OCN).

Methodology:

- Scaffold Preparation & Seeding: Sterilize scaffolds (Protocol 3.1) in 70% ethanol (2h), UV irradiate per side (30 min). Pre-wet in culture medium. Seed hMSCs at a density of 50,000 cells/scaffold using a static drop method. Incubate for 2h, then add medium.

- Proliferation (Days 1, 3, 7): At each time point, incubate scaffolds in AlamarBlue reagent (10% v/v in medium) for 3h. Measure fluorescence (Ex560/Em590). Construct growth curves.

- Cell Morphology (Day 3): Fix samples in 4% PFA, dehydrate in graded ethanol series, critical point dry, and sputter-coat with gold. Image using SEM to assess cell attachment and morphology within pores.

- Osteogenic Differentiation (Days 7, 14, 21):

- Gene Expression: Lyse cells, extract RNA, perform reverse transcription. Run qPCR for RUNX2, OPN, OCN. Normalize to GAPDH. Use the 2^(-ΔΔCt) method.

- Biochemical Activity: Quantify Alkaline Phosphatase (ALP) activity using a pNPP assay at day 14. Measure extracellular calcium deposition at day 21 via Alizarin Red S staining and quantification.

Visualizations

Diagram 1: Workflow for Patient-Specific Scaffold Production

Diagram 2: Porosity-Driven Osteogenic Signaling Pathways

The Scientist's Toolkit: Key Research Reagent Solutions

| Item Name / Solution | Supplier Examples | Function in Scaffold Research |

|---|---|---|

| Polycaprolactone (PCL) | Sigma-Aldrich, Corbion | Biodegradable, FDA-approved polymer providing structural integrity and tunable degradation kinetics for extrusion printing. |

| Nano-Hydroxyapatite (nHA) | Berkeley Advanced Biomaterials, Fluidinova | Bioactive ceramic mimicking bone mineral, enhances osteoconductivity and compressive strength of composite inks. |

| Human Mesenchymal Stem Cells (hMSCs) | Lonza, RoosterBio | Primary cell model for evaluating scaffold biocompatibility, proliferation, and osteogenic differentiation potential. |

| Osteogenesis Assay Kit | MilliporeSigma, Abcam | Pre-optimized reagent set for quantifying early (ALP) and late (mineralization) markers of bone formation. |

| AlamarBlue Cell Viability Reagent | Thermo Fisher, Bio-Rad | Resazurin-based fluorometric assay for non-destructive, longitudinal monitoring of cell proliferation on 3D scaffolds. |

| Critical Point Dryer | Leica, Tousimis | Essential for preparing hydrated, porous scaffold-cell constructs for SEM imaging without structural collapse. |

Within the broader thesis on 3D printing of synthetic bone graft scaffolds, three interconnected parameters are critical for osteogenic success: pore size, interconnectivity, and mechanical competence. These parameters dictate cellular infiltration, vascularization, nutrient/waste exchange, and load-bearing capacity. This document provides application notes and protocols for designing and characterizing these core parameters in 3D-printed scaffolds for bone tissue engineering and drug delivery applications.

Application Notes

Pore Size: Balancing Surface Area and Cell Phenotype

Pore size directly influences cell attachment, migration, and differentiation. While smaller pores increase specific surface area for protein adsorption, larger pores facilitate vascular ingrowth and osteogenesis.

Summary of Quantitative Data: Osteogenic Response vs. Pore Size Table 1: Influence of scaffold pore size on biological outcomes in bone regeneration models.

| Pore Size Range (µm) | Primary Material(s) Tested | Key Biological Outcome | Optimal for |

|---|---|---|---|

| < 100 µm | PCL, HA | High cell adhesion, limited infiltration. Increased osteochondral differentiation in some models. | In vitro cell seeding efficiency. |

| 100 - 300 µm | β-TCP, PCL-TCP composites | Enhanced osteogenic differentiation of MSCs. Significant bone ingrowth in vivo. | Early osteogenesis, protein/Drug delivery. |

| 300 - 600 µm | PLA, PCL, Bioglass | Robust vascularization. Highest rates of new bone formation and mineralization. | Vascularized bone regeneration. |

| > 600 µm | Titanium, ceramic composites | Potential for rapid vascular invasion; may compromise mechanical integrity if struts are thin. | Bulk defect repair with pre-vascularization strategies. |

Interconnectivity: The Conduit for Tissue Integration

Interconnectivity ensures pore accessibility, preventing cell entrapment and necrotic cores. It is quantified by parameters like connectivity density and tortuosity.

Summary of Quantitative Data: Interconnectivity Metrics Table 2: Common metrics for quantifying scaffold interconnectivity from micro-CT analysis.

| Metric | Definition | Target Range for Bone Scaffolds | Measurement Technique |

|---|---|---|---|

| Porosity (%) | Volume fraction of void space. | 60-80% (balance with mechanics) | Micro-CT, gravimetric analysis. |

| Connectivity Density (1/mm³) | Number of redundant connections per unit volume. | > 10-20 is considered well-interconnected. | Micro-CT (3D Euler number analysis). |

| Tortuosity | Measure of path winding; 1 is a straight channel. | Aim for low values (1.5-2.5) for efficient transport. | Computational analysis of 3D models. |

| Mean Pore Size (µm) | Average diameter of interconnected voids. | Target 300-600 µm (see Table 1). | Micro-CT, mercury porosimetry. |

Mechanical Competence: Mimicking the Native Bone Environment

Scaffold stiffness and strength must match the implantation site to avoid stress shielding or collapse, while providing appropriate mechanobiological cues.

Summary of Quantitative Data: Target Mechanical Properties Table 3: Target mechanical properties for 3D-printed bone graft scaffolds relative to native bone.

| Property | Cancellous Bone | Cortical Bone | Typical 3D-Printed Scaffold Target (Porosity ~70%) |

|---|---|---|---|

| Compressive Modulus (MPa) | 50 - 500 | 7,000 - 20,000 | 50 - 500 (site-dependent) |

| Compressive Strength (MPa) | 2 - 12 | 130 - 205 | 2 - 10 |

| Tensile Strength (MPa) | 1 - 5 | 50 - 150 | 1 - 15 (highly material-dependent) |

| Flexural Modulus (GPa) | 1 - 5 | 7 - 25 | 0.1 - 3 |

Experimental Protocols

Protocol 1: Design & 3D Printing of Scaffolds with Controlled Parameters

Objective: Fabricate polymer-ceramic composite scaffolds (e.g., PCL/β-TCP) with defined pore architectures.

Materials:

- PCL pellets (Mw ~50,000), β-TCP nanoparticles.

- Solvent (Chloroform) or Fused Deposition Modeling (FDM) printer.

- CAD software (e.g., SolidWorks), slicing software (e.g., Cura).

Methodology:

- Design: Create a CAD model of a scaffold (e.g., 10x10x10 mm) with a repeating orthogonal or gyroid unit cell. Precisely define strut diameter and pore size (e.g., 300 µm pores, 250 µm struts).

- Material Preparation:

- For solvent-casting 3D printing: Dissolve PCL (15% w/v) in chloroform. Disperse 20-30 wt% β-TCP nanoparticles via probe sonication.

- For FDM: Produce composite filament via hot-melt extrusion of PCL/β-TCP blend.

- Printing: Load material into printer. Set parameters (Nozzle: 250-300°C, Bed: 40-60°C, Speed: 5-10 mm/s, Layer Height: 100-200 µm). Print scaffolds.

- Post-processing: Vacuum-dry to remove residual solvent (if used). Sterilize via ethylene oxide or ethanol immersion for cell studies.

Protocol 2: Micro-CT Characterization of Pore Size & Interconnectivity

Objective: Quantitatively analyze the internal 3D architecture of a printed scaffold.

Materials:

- Micro-CT scanner (e.g., SkyScan, µCT).

- Image analysis software (e.g., CTAn, ImageJ, Dragonfly).

Methodology:

- Sample Mounting: Secure scaffold on sample holder. Ensure no movement.

- Scanning: Set scanning parameters (e.g., Voltage: 60 kV, Current: 166 µA, Pixel Size: 5-10 µm, Rotation Step: 0.4°, Filter: Al 0.5 mm). Acquire ~1000 projection images.

- Reconstruction: Use manufacturer's software to reconstruct cross-sectional slices from projections.

- Analysis (in CTAn):

- Threshold images to separate scaffold material from void space.

- Perform 3D analysis to calculate Total Porosity (%), Total Volume, and Object Surface.

- Perform "Analysis of Interconnectivity" to calculate Connectivity Density and Closed Porosity.

- Use "Sphere Fitting" or "Local Thickness" algorithm to calculate Mean Pore Size Distribution.

Protocol 3: Uniaxial Compression Testing for Mechanical Competence

Objective: Determine the compressive modulus and strength of a cylindrical scaffold.

Materials:

- Universal mechanical tester (e.g., Instron, Zwick).

- ± 1 kN load cell, parallel compression platens.

Methodology:

- Sample Prep: Fabricate cylindrical scaffolds (e.g., Ø6 mm x 12 mm height). Measure exact dimensions with calipers.

- Tester Setup: Install platens. Calibrate load cell. Set crosshead speed to 1 mm/min.

- Mounting: Center scaffold on lower platen. Lower upper platen until it just contacts the sample (pre-load of ~0.1 N).

- Testing: Compress sample to 50-60% strain or until structural failure. Record load (N) vs. displacement (mm) data.

- Data Analysis:

- Convert displacement to Strain (∆L / L₀) and load to Stress (Load / A₀).

- Plot stress-strain curve. Identify linear elastic region (typically 2-10% strain).

- Calculate Compressive Modulus (E) as the slope of the linear region.

- Identify Compressive Strength as the first peak stress or stress at 10% strain (per ASTM F2450).

Visualization: Parameter Interplay and Workflow

Title: Scaffold Design-Analysis Feedback Loop

Title: Scaffold Cues Drive Osteogenic Signaling

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential materials and reagents for 3D-printed bone scaffold research.

| Item | Function/Application | Example/Note |

|---|---|---|

| Bioactive Ceramics (β-TCP, HA) | Osteoconductive filler; improves compressive strength and bioactivity. | Sigma-Aldrich (product # 642991), Berkeley Advanced Biomaterials. |

| Biodegradable Polymers (PCL, PLA, PLGA) | Printable matrix providing structural integrity and tunable degradation. | Corbion (PURASORB), Lactel Absorbable Polymers. |

| Human Mesenchymal Stem Cells (hMSCs) | Gold-standard cell model for in vitro osteogenic differentiation studies. | Lonza (PT-2501), ATCC (PCS-500-011). |

| Osteogenic Induction Media | Chemically defined medium to drive stem cell differentiation towards osteoblasts. | Contains dexamethasone, ascorbate, β-glycerophosphate. Thermo Fisher (A1007201). |

| Micro-CT Calibration Phantom | For accurate quantitative density and morphometric analysis of scans. | Bruker’s hydroxyapatite phantoms with known density. |

| AlamarBlue or PrestoBlue | Resazurin-based assay for non-destructive monitoring of cell viability/proliferation on scaffolds. | Thermo Fisher (DAL1100). |

| Osteogenesis Assay Kit (PNPP) | Quantifies alkaline phosphatase (ALP) activity, an early osteogenic marker. | Sigma-Aldrich (AP0100). |

| µCT Voxel Analysis Software | Essential for 3D quantification of porosity, pore size, and interconnectivity. | Bruker’s CTAn, Thermo Fisher’s Amira-Avizo. |

Application Notes

In the context of 3D-printed synthetic bone graft scaffolds, the triad of osteoconduction, osteoinduction, and osseointegration defines the success of the implant. Osteoconduction provides the 3D architecture for bone cell migration and attachment. Osteoinduction recruits and stimulates progenitor cells to differentiate into osteoblasts. Osseointegration ensures direct structural and functional anchorage of the implant to living bone. The goal of modern scaffold design is to engineer a single construct that optimally fulfills all three functions.

Table 1: Scaffold Design Parameters Influencing Bone Regeneration Mechanisms

| Parameter | Optimal Range for Osteoconduction | Critical Value for Osteoinduction | Target for Osseointegration | Measurement Technique |

|---|---|---|---|---|

| Porosity | 60-80% | >50% (for cell/vascular invasion) | Interconnected porosity >100µm | Micro-CT Analysis |

| Pore Size | 100-500 µm | 200-400 µm (for osteogenesis) | Pores >100µm for bone ingrowth | SEM Image Analysis |

| Compressive Modulus | 0.05-2 GPa (matching trabecular bone) | Sufficient for mechanical signaling | Matching adjacent bone tissue | Mechanical Compression Test |

| Surface Roughness (Ra) | 1-10 µm | Enhances protein adsorption | 1-5 µm for direct bone contact | Atomic Force Microscopy (AFM) |

| Degradation Rate | 0.1-0.5 mm/month | Coupled with bone formation rate | Stable interface after 12 weeks | Mass Loss Assay (in vitro) |

| BMP-2 Loading Dose | N/A | 0.1-10 µg/mg scaffold (low dose) | N/A | ELISA |

Table 2: In Vivo Outcomes of 3D-Printed Scaffolds in Critical-Sized Defect Models (12 weeks)

| Scaffold Material + Modification | New Bone Volume (%) | Bone-Material Contact (%) | Compressive Strength (MPa) | Study Model (Animal) |

|---|---|---|---|---|

| β-TCP (Osteoconductive only) | 25-35% | 40-50% | 2-5 | Rabbit Femoral Condyle |

| β-TCP + BMP-2 (5µg/mg) | 55-70% | 65-75% | 8-12 | Rat Calvarial Defect |

| PCL + Nano-HA | 30-45% | 50-60% | 10-15 | Sheep Tibia |

| PCL + Nano-HA + VEGF | 50-65% | 70-80% | 12-18 | Rabbit Mandible |

| Silicate Bioactive Glass | 40-55% | 60-70% | 15-25 | Porcine Vertebra |

Experimental Protocols

Protocol: Evaluating Osteoconduction via Human Mesenchymal Stem Cell (hMSC) Seeding and Migration

Objective: To assess the 3D scaffold's ability to support hMSC attachment, proliferation, and migration—key indicators of osteoconduction.

Materials:

- Sterile, 3D-printed scaffold discs (5mm diameter x 2mm height).

- Human Mesenchymal Stem Cells (hMSCs, passage 3-5).

- Standard culture medium: α-MEM, 10% FBS, 1% Pen/Strep.

- CellTracker Green CMFDA dye.

- 4% paraformaldehyde (PFA).

- Confocal microscopy setup.

Procedure:

- Scaffold Pre-conditioning: Sterilize scaffolds (ethanol 70%, UV). Pre-wet in culture medium for 2 hours at 37°C.

- Cell Seeding: Label hMSCs with CellTracker Green (5 µM, 30 min). Prepare a cell suspension of 2x10^6 cells/mL. Pipette 20 µL of suspension directly onto the top surface of each scaffold (40,000 cells/scaffold). Incubate for 2 hours to allow initial attachment.

- Static Culture: Add medium to submerge scaffolds. Culture for 1, 3, and 7 days.

- Analysis:

- Day 1 Attachment: Fix samples with 4% PFA for 30 min. Image via confocal microscopy (Z-stack). Calculate attachment efficiency: (Number of attached cells / Number of seeded cells) x 100.

- Day 3 & 7 Migration/Proliferation: Fix as above. Use Z-stacks to visualize cell penetration depth. Use image analysis software (e.g., Fiji/ImageJ) to measure the maximum distance of cells from the seeding surface in 3 random fields.

Protocol: Assessing Osteoinductive Potential via Ectopic Bone Formation (Rodent Subcutaneous Model)

Objective: To determine the scaffold's intrinsic or growth-factor-loaded ability to induce de novo bone formation in a non-bony site.

Materials:

- Test scaffolds (5x5x2 mm), with or without osteogenic factors (e.g., 2 µg/mg scaffold of rhBMP-2).

- 8-10 week old immunodeficient mice (e.g., NU/J).

- Isoflurane anesthesia system.

- Surgical tools, sutures.

- Micro-CT scanner, histology supplies.

Procedure:

- Implantation: Anesthetize mouse. Make two small dorsal incisions. Create subcutaneous pockets by blunt dissection. Insert one test and one control scaffold per animal into separate pockets. Close incisions.

- Time Course: Maintain animals for 4 and 8 weeks (n=5 per group per time point).

- Harvest and Analysis:

- Micro-CT: Euthanize animals. Explant scaffolds with surrounding tissue. Scan at 10 µm isotropic resolution. Quantify mineralized tissue volume (BV, mm³) within the scaffold boundaries using a standardized threshold.

- Histology: Fix samples in 4% PFA, decalcify, paraffin-embed. Section (5 µm) and stain with Hematoxylin & Eosin (H&E) and Masson's Trichrome. Score for the presence of osteoblasts, osteocytes, and mature bone matrix.

Protocol: Quantifying Osseointegration in a Load-Bearing Defect Model

Objective: To evaluate the direct structural and functional connection between bone and implant under biomechanical stress.

Materials:

- 3D-printed cylindrical scaffolds (3mm diameter x 6mm length) designed for press-fit.

- Mature New Zealand White Rabbits (n=6 per group).

- Surgical drill and trephine bur.

- Biomechanical push-out test apparatus.

- Undecalcified histology supplies (e.g., methylmethacrylate embedding).

Procedure:

- Surgical Implantation: Anesthetize rabbit. Create a bilateral critical-sized defect (3.5mm) in the femoral condyles. Press-fit the sterilized scaffold into one defect; leave contralateral as empty control or fill with a commercial graft. Close in layers.

- Healing Period: Allow 12 weeks of healing with unrestricted weight-bearing.

- Terminal Analysis:

- Biomechanical Push-Out Test: Euthanize and harvest femurs. Trim to isolate the implant site. Mount bone on a support jig with a 2mm clearance. Use a calibrated plunger to apply a continuous displacement (1 mm/min) to the implant until failure. Record maximum shear strength (MPa) = Peak Force / (π * diameter * implant length).

- Histomorphometry: Process undecalcified bone-implant samples for resin embedding. Cut and polish longitudinal sections. Stain with Toluidine Blue or Stevenel's Blue/Van Gieson. Using light microscopy, measure the Bone-to-Implant Contact (BIC%) = (Length of scaffold surface in direct contact with bone / Total scaffold perimeter) x 100.

Diagrams

Title: BMP-2 Signaling Pathway in Scaffold Osteoinduction

Title: Integrated Preclinical Testing Workflow for Bone Scaffolds

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions for Bone Scaffold Evaluation

| Reagent / Material | Supplier Examples | Primary Function in Experiments |

|---|---|---|

| Recombinant Human BMP-2 | PeproTech, Medtronic | Gold-standard osteoinductive protein; loaded onto scaffolds to test and enhance bone induction. |

| Human Mesenchymal Stem Cells (hMSCs) | Lonza, ATCC | Primary cell model for assessing scaffold cytocompatibility, osteoconduction, and differentiation. |

| Osteogenic Media Supplement (Dex, AA, β-GP) | Sigma-Aldrich | Induces osteogenic differentiation of hMSCs in vitro; tests scaffold's support for osteogenesis. |

| CellTracker Green CMFDA | Thermo Fisher Scientific | Fluorescent cytoplasmic dye for long-term tracking of cell attachment, viability, and migration in 3D. |

| AlamarBlue / MTS Assay Kit | Thermo Fisher, Abcam | Colorimetric/fluorometric assays for quantifying cell proliferation on 3D scaffolds. |

| Micro-CT Calibration Phantom | Scanco Medical, Bruker | Hydroxyapatite phantom for accurate quantification of bone mineral density in explanted scaffolds. |

| Methylmethacrylate (MMA) Embedding Kit | Sigma-Aldrich, Polysciences | For processing undecalcified bone-implant samples, preserving the mineralized tissue-implant interface for BIC analysis. |

Current Clinical Limitations Driving Synthetic Scaffold Innovation

Within the broader thesis on the 3D printing of synthetic bone graft scaffolds, this document outlines key clinical limitations and provides detailed application notes and protocols to address them. The drive for synthetic scaffold innovation stems from significant shortcomings in current gold-standard treatments, such as autografts and allografts.

Clinical Limitations & Quantitative Drivers

The primary limitations of existing bone graft solutions are summarized in the table below.

Table 1: Quantitative Clinical Limitations of Current Bone Graft Solutions

| Limitation Category | Autograft Data | Allograft Data | Clinical Impact |

|---|---|---|---|

| Donor Site Morbidity | Incidence: 8-39% (Avg. 20%). Chronic pain in ~10% of patients. | Not Applicable. | Increased post-op pain, extended hospitalization, secondary surgical site complications. |

| Supply Volume Limitation | Max harvestable volume: ~50-100 cm³ (iliac crest). | Limited by donor availability; processing reduces viable osteogenic cells. | Inadequate for large craniofacial or spinal defects (>5 cm). |

| Infection/Immunogenicity Risk | Risk negligible (autologous). | Disease transmission risk: ~1 in 1.6 million (screened). Graft rejection in 13-20% of cases. | Leads to graft failure, necessitates revision surgery, increases antibiotic use. |

| Variable/Bone Healing Rates | Fusion success rate: 80-95% (spine). | Fusion success rate: 65-80% (spine). Non-union in up to 25% of large defects. | Extended patient immobility, increased healthcare costs, poor functional outcomes. |

| Inconsistent Mechanical Properties | High initial strength, but variable. | Demineralized: low strength (<2 MPa). Structural: strong but brittle, stress-shielding risk (Elastic Modulus: 10-20 GPa vs. native bone's 0.5-20 GPa). | Risk of mechanical failure, implant loosening, and inhibited bone remodeling. |

Application Notes: Addressing Limitations via 3D-Printed Synthetic Scaffolds

AN-1: Addressing Donor Site Morbidity & Supply Limitation

- Approach: Patient-specific, defect-filling scaffolds via medical image-based 3D printing.

- Protocol Basis: Use CT-derived DICOM files to create a 3D model of the defect. Software (e.g., 3D Slicer) is used to design a porous scaffold that precisely fits the void. This eliminates secondary surgery and enables repair of arbitrarily large defects.

AN-2: Enhancing Osteointegration & Healing Rates

- Approach: Bioactive material incorporation (e.g., hydroxyapatite, β-Tricalcium Phosphate) and controlled architecture.

- Protocol Basis: Print with composite materials (e.g., PCL/β-TCP). The scaffold's pore size (optimal 300-600 µm) and interconnectivity (>90%) are designed to promote vascularization and cell migration, directly targeting low fusion rates.

AN-3: Mitigating Infection Risk

- Approach: Localized, sustained antibiotic or antimicrobial ion (e.g., Ag⁺, Zn²⁺) delivery.

- Protocol Basis: Drugs/ions are incorporated into the printing ink (e.g., into a PLGA polymer matrix). A biphasic release profile—rapid initial to prevent biofilm formation, followed by sustained release—is engineered via core-shell printing or polymer blend selection.

AN-4: Matching Mechanical Properties

- Approach: Multi-material and graded-structure printing.

- Protocol Basis: Using a multi-extruder printer, combine a stiff, osteoconductive ceramic (e.g., HA) at the bone interface with a tougher, more flexible polymer (e.g., PEEK) in the core. This gradation mimics the cortical-cancellous bone transition and minimizes stress shielding.

Detailed Experimental Protocols

Protocol P-1: Design & 3D Printing of a Bioactive Composite Scaffold

Aim: To fabricate a patient-specific, osteoconductive scaffold for a critical-sized bone defect. Materials:

- Medical-grade Polycaprolactone (PCL) pellets.

- β-Tricalcium Phosphate (β-TCP) powder, <100 nm particle size.

- Solvent: Chloroform.

- Fused Deposition Modeling (FDM) or Direct Ink Writing (DIW) 3D printer.

- CT scan data (DICOM) of the bone defect.

Methodology:

- Scaffold Design: Import DICOM files into segmentation software (e.g., 3D Slicer). Isolate the bone defect and generate a 3D STL file. Import the STL into scaffold design software (e.g., Autodesk Netfabb). Design a porous lattice structure (e.g., gyroid) within the defect boundary. Set pore size to 450 µm and porosity to 70%. Export as G-code.

- Ink/Feedstock Preparation: Prepare a composite of 70% PCL / 30% β-TCP by weight. Dissolve PCL pellets in chloroform (20% w/v). Stir in β-TCP powder vigorously. Cast the mixture into a mold and evaporate the solvent under a fume hood to create a solid composite filament (for FDM) or concentrate for a DIW paste.

- Printing: For FDM: Load composite filament. Set nozzle temp to 120°C, bed temp to 60°C, layer height to 150 µm, and print speed to 10 mm/s. Initiate print using the prepared G-code. For DIW: Load paste into a syringe. Use a 25G nozzle. Set pressure to 220 kPa and print speed to 8 mm/s.

- Post-Processing: Dry scaffolds in a vacuum desiccator for 48 hours. Sterilize using gamma irradiation (25 kGy).

Protocol P-2: In Vitro Assessment of Osteogenic Differentiation

Aim: To evaluate the scaffold's ability to support mesenchymal stem cell (MSC) adhesion, proliferation, and osteogenic differentiation. Materials:

- Human Bone Marrow-derived MSCs (hBM-MSCs), passage 3-5.

- Osteogenic medium: α-MEM, 10% FBS, 10 mM β-glycerophosphate, 50 µg/mL ascorbic acid, 100 nM dexamethasone.

- AlamarBlue assay reagent.

- Quant-iT PicoGreen dsDNA assay kit.

- Alkaline Phosphatase (ALP) detection kit (e.g., SigmaFast BCIP/NBT).

- OsteoImage mineralization assay kit.

Methodology:

- Seeding: Sterilize scaffolds (P-1 output) in 70% ethanol, wash with PBS. Pre-wet in culture medium. Seed hBM-MSCs at a density of 5 x 10⁴ cells/scaffold in a low-attachment plate. Allow 2 hours for adhesion before adding medium.

- Proliferation (Days 1, 3, 7): At each time point, incubate scaffolds in 10% AlamarBlue/medium for 4 hours. Measure fluorescence (Ex560/Em590). Perform PicoGreen assay on lysed samples for total DNA content.

- Early Differentiation (Day 7, 14): Fix cells on scaffold with 4% PFA. Incubate with BCIP/NBT solution per kit instructions. Quantify ALP stain by eluting with 10% cetylpyridinium chloride and measuring absorbance at 620 nm.

- Late Differentiation/Mineralization (Day 21, 28): Wash scaffolds. Perform OsteoImage staining per kit protocol to label hydroxyapatite deposits. Visualize via fluorescence microscopy (Ex495/Em520). Quantify by eluting stain and measuring fluorescence.

Protocol P-3: Sustained Antibiotic Release Kinetics

Aim: To characterize the release profile of vancomycin from a core-shell printed scaffold. Materials:

- PLGA (50:50, acid-terminated).

- Vancomycin hydrochloride.

- Phosphate Buffered Saline (PBS), pH 7.4.

- Coaxial printing nozzle for DIW printer.

- UV-Vis Spectrophotometer.

Methodology:

- Ink Preparation: Shell ink: 30% w/v PLGA in DMSO. Core ink: 10% w/v PLGA + 5% w/v vancomycin in deionized water.

- Printing: Use a coaxial printhead. Print scaffold using parameters from P-1, with core-shell filament. Freeze-dry prints to remove solvents.

- Release Study: (n=5) Immerse each scaffold in 5 mL PBS at 37°C under gentle agitation (50 rpm). At predetermined intervals (1, 3, 6, 12, 24, 48, 72h, then daily to 28 days), remove and replace the entire release medium.

- Quantification: Analyze collected release medium for vancomycin concentration using UV-Vis at 280 nm. Plot cumulative release (%) vs. time. Fit data to Korsmeyer-Peppas model to determine release mechanism.

Visualizations

Diagram 1: From Clinical Problem to Experimental Solution

Diagram 2: Scaffold Development & Testing Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for 3D-Printed Bone Scaffold Research

| Item & Example Product | Function in Research | Key Application/Protocol |

|---|---|---|

| Medical-Grade PCL(e.g., PURASORB PC12) | Biocompatible, biodegradable polymer backbone. Provides initial structural integrity and tunable degradation kinetics. | Core material for melt-based 3D printing (P-1). |

| β-Tricalcium Phosphate (β-TCP) Powder(e.g., Sigma-Aldrieb 21218) | Osteoconductive ceramic. Enhances bioactivity, promotes cell adhesion, and modifies composite degradation & strength. | Composite fabrication for osteointegration (P-1, P-2). |

| Human Bone Marrow MSCs(e.g., Lonza PT-2501) | Gold-standard primary cell model. Used to assess scaffold biocompatibility, proliferation, and osteogenic differentiation potential. | In vitro biological validation (P-2). |

| Osteogenic Supplement Kit(e.g., Gibco A10456-01) | Defined cocktail (Dexamethasone, AA, β-GP) to induce and maintain MSC differentiation down the osteoblastic lineage in culture. | In vitro differentiation assays (P-2). |

| AlamarBlue Cell Viability Reagent(e.g., Invitrogen DAL1025) | Resazurin-based fluorometric/colorimetric assay. Measures metabolic activity as a proxy for cell proliferation on scaffolds (non-destructive). | Time-point proliferation assays (P-2). |

| PLGA (50:50)(e.g., Lactel B6010-2) | Co-polymer of lactide and glycolide. Erodible polymer used for creating drug delivery matrices with predictable release profiles. | Fabrication of drug-eluting scaffolds (P-3). |

| Coaxial Printing Nozzle(e.g., Nordson EFD 7018372) | Specialized printhead allowing simultaneous extrusion of two materials in a core-shell configuration. Enables advanced drug encapsulation. | Core-shell scaffold fabrication for sustained release (P-3). |

Fabrication in Focus: Techniques and Protocols for Printing Bone Scaffolds

Within the thesis research on 3D printing synthetic bone graft scaffolds, the selection of fabrication technology is paramount. It dictates scaffold architecture, material selection, mechanical properties, and biological performance. This application note details three predominant technologies—Selective Laser Sintering (SLS), Digital Light Processing (DLP), and Fused Deposition Modeling/Direct Ink Writing (FDM/DIW)—providing protocols and comparative analysis tailored for bone tissue engineering research.

Table 1: Core Characteristics of SLS, DLP, and FDM/DIW for Bone Scaffold Fabrication

| Feature | Selective Laser Sintering (SLS) | Digital Light Processing (DLP) | Fused Deposition Modeling / Direct Ink Writing (FDM/DIW) |

|---|---|---|---|

| Basic Principle | Powder bed fusion by laser | Vat photopolymerization by projected UV light | Material extrusion through nozzle |

| Typical Materials | Thermoplastics (PCL, PA), composite powders (e.g., PCL/β-TCP, PEEK/HA) | Photopolymerizable resins (acrylates, methacrylates) with ceramic (e.g., HA) or polymer fillers | Thermoplastics (PCL, PLGA) in FDM; Hydrogels (alginate, gelatin), pastes (ceramic, composite) in DIW |

| Typical Resolution | 50 - 150 µm | 25 - 100 µm | FDM: 100 - 400 µm; DIW: 50 - 500 µm |

| Key Advantages | No need for supports; porous structures; excellent for complex geometries. | High resolution and speed; smooth surface finish. | FDM: Low cost, robust. DIW: Room temp processing, cell encapsulation (bioprinting). |

| Key Limitations | High temp; powder removal; limited to semi-crystalline materials. | Material brittleness; need for post-curing; limited biocompatible resins. | FDM: High temp, limited materials. DIW: Low mechanical strength, requires rapid gelation. |

| Primary Scaffold Metric | Mechanical strength, porosity from powder size. | Architectural fidelity, feature resolution. | Porosity from laydown pattern, biocompatibility (DIW). |

Table 2: Quantitative Performance in Bone Scaffold Context (Typical Reported Ranges)

| Parameter | SLS | DLP | FDM | DIW |

|---|---|---|---|---|

| Compressive Strength (MPa) | 10 - 150 (composite-dependent) | 5 - 100 (resin/composite-dependent) | 2 - 80 (material-dependent) | 0.1 - 10 (highly formulation-dependent) |

| Porosity Range (%) | 30 - 70 | 20 - 80 (design-dependent) | 20 - 60 (design-dependent) | 20 - 70 |

| Feature Size (µm) | ~100 | ~50 | ~200 | ~150 |

| Cell Viability in Bioprinting | Not applicable (high temp) | Low (cytotoxic resins, post-cure) | Low (high temp) | High (70-95+%) (room temp, bioinks) |

Application Notes & Experimental Protocols

Protocol 2.1: SLS Fabrication of PCL/β-TCP Composite Scaffolds

Aim: Fabricate osteoconductive bone scaffolds with enhanced mechanical properties. Materials: Polycaprolactone (PCL) powder, β-Tricalcium Phosphate (β-TCP) powder (20-30% wt), SLS system (e.g., Formlabs Fuse 1). Procedure:

- Powder Preparation: Blend PCL and β-TCP powders in a turbula mixer for 45 mins. Sieve to < 100 µm.

- Process Optimization: Calibrate laser power (e.g., 5-10 W), scan speed (e.g., 1000-2000 mm/s), and layer thickness (e.g., 100 µm) using test cubes to achieve full particle fusion.

- Scaffold Printing: Import scaffold design (e.g., gyroid, 500 µm pore size). Fill build chamber with composite powder. Print with optimized parameters. Maintain bed temperature just below PCL melting point (~55°C).

- Post-Processing: Allow chamber to cool. Carefully remove printed part. Use compressed air and soft brushes to remove unsintered powder. Clean ultrasonically in ethanol if needed. Analysis: Micro-CT for porosity/pore interconnectivity; SEM for surface morphology; compression testing per ASTM D695.

Protocol 2.2: DLP Fabrication of Hydroxyapatite-Filled Resin Scaffolds

Aim: Create high-resolution, ceramic-rich scaffolds mimicking bone mineral. Materials: Biocompatible methacrylate resin (e.g., PEGDMA), nano-hydroxyapatite (nHA) (40% wt), photoinitiator (TPO), DLP printer (e.g., B9Creator). Procedure:

- Resin Formulation: Dissolve TPO (0.5% wt) in PEGDMA. Gradually incorporate nHA under mechanical stirring (2 hrs), followed by sonication (30 mins) to break agglomerates.

- Printing Parameters: Slice model with 50 µm layer thickness. Set exposure time (e.g., 2-4 sec/layer) based on resin viscosity and filler content. Print.

- Post-Curing & Cleaning: Rinse printed scaffold in isopropanol to remove uncured resin. Post-cure under UV light (365 nm) for 20 mins per side.

- Thermal Debinding (Optional): For pure ceramic scaffolds, perform thermal cycle to burn out polymer and sinter nHA. Analysis: SEM/EDX for ceramic distribution; FTIR for polymer conversion; mechanical testing.

Protocol 2.3: DIW (Bioprinting) of Cell-Laden Alginate/Gelatin Scaffolds

Aim: Fabricate osteogenic scaffolds with encapsulated mesenchymal stem cells (MSCs). Materials: Alginate (4% w/v), gelatin (8% w/v), CaCl₂ crosslinker (100 mM), hMSCs, DIW/bioprinter (e.g., BIO X) with temperature-controlled printhead. Procedure:

- Bioink Preparation: Dissolve alginate and gelatin in PBS at 37°C. Sterile filter. Cool to 25°C to induce gelatin partial gelation. Mix with hMSCs (1-5x10^6 cells/mL) gently.

- Printing Setup: Load bioink into syringe, maintain at 18-22°C. Use conical nozzle (22-27G). Design a 3D grid structure.

- Printing & Crosslinking: Print into a CaCl₂ solution bath (co-axial crosslinking) or onto a substrate with subsequent aerosol spray of CaCl₂.

- Post-Printing: Incubate scaffolds in cell culture medium at 37°C. Gelatin will melt, leaving a porous alginate network. Analysis: Live/dead assay at days 1, 3, 7; Alizarin Red staining for mineralization after 14-21 days in osteogenic medium.

Visualized Workflows & Pathways

Title: 3D Printing Technology Workflow Comparison

Title: Key Signaling in Scaffold-Mediated Osteogenesis

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Reagents for 3D Printed Bone Scaffold Research

| Item | Function & Relevance | Example(s) |

|---|---|---|

| Polycaprolactone (PCL) | Biodegradable, FDA-approved thermoplastic; excellent for SLS and FDM due to low melting point. Provides structural integrity. | Sigma-Aldrich, Corbion Purac |

| β-Tricalcium Phosphate (β-TCP) | Osteoconductive ceramic; blended with polymers to enhance bioactivity and mechanical strength. | Merck, CAM Bioceramics |

| Nano-Hydroxyapatite (nHA) | Primary mineral component of bone; used as filler in DLP resins and DIW pastes to promote osteointegration. | Berkeley Advanced Biomaterials, Fluidinova |

| Poly(ethylene glycol) dimethacrylate (PEGDMA) | Photopolymerizable, hydrophilic resin for DLP; allows tuning of mechanical properties and degradation. | Sigma-Aldrich, Polysciences |

| Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Biocompatible photoinitiator for DLP bioprinting; cures with 405 nm light, less cytotoxic than others. | Tokyo Chemical Industry |

| Alginate | Natural polysaccharide for DIW bioinks; ionically crosslinkable (Ca²⁺), provides mild gelation for cell encapsulation. | Novamatrix, PRONOVA UP MVG |

| Gelatin Methacryloyl (GelMA) | Photocrosslinkable hydrogel; combines bioactivity of gelatin with DLP/DIW printability. Used in advanced bioinks. | Advanced BioMatrix, ESI BIO |

| Recombinant Human BMP-2 | Growth factor; incorporated into scaffolds to induce potent osteogenic differentiation of MSCs. | PeproTech, R&D Systems |

| AlamarBlue/MTT Assay Kit | For quantifying metabolic activity and cytotoxicity of scaffolds post-printing. | Thermo Fisher Scientific, Abcam |

| Alizarin Red S | Histochemical stain to detect and quantify calcium deposits, indicating osteogenic differentiation. | Sigma-Aldrich |

Application Notes

The integration of medical imaging with 3D printing is revolutionizing the development of patient-specific synthetic bone graft scaffolds. This digital workflow enables the creation of scaffolds that precisely match a bone defect's geometry and internal architecture, a critical factor for successful osseointegration and vascularization. For researchers in bone tissue engineering, this pathway allows for the systematic investigation of how scaffold macro- and micro-architecture (pore size, connectivity, strut thickness) influences mechanical properties, cell seeding efficiency, nutrient diffusion, and ultimately, in vivo bone regeneration outcomes. The reproducibility afforded by this digital chain is essential for high-fidelity experimental design in drug development, where controlled release from a printed scaffold can be studied in a consistent 3D environment.

Key quantitative data from recent literature on scaffold design and outcomes is summarized below:

Table 1: Quantitative Parameters for 3D Printed Bone Scaffolds from Medical Imaging

| Parameter | Typical Range / Value | Significance for Bone Graft Research | Source (Example) |

|---|---|---|---|

| CT Scan Resolution | 50 - 500 µm (clinical); 1 - 50 µm (micro-CT) | Determines the fidelity of defect geometry capture and trabecular bone architecture replication. | Micro-CT studies (2023) |

| Segmentation Threshold (HU) | 200 - 1000 Hounsfield Units (for bone) | Critical for isolating bone tissue from soft tissue; affects final model accuracy. | Orthopaedic imaging protocols |

| Scaffold Porosity (Designed) | 60% - 80% | Optimizes trade-off between mechanical strength and space for cell infiltration/tissue ingrowth. | Biomaterials research reviews |

| Mean Pore Size (Target) | 300 - 600 µm | Promotes osteogenesis and vascularization. Pore size <100µm limits cell migration. | Metanalysis, 2024 |

| Print Layer Height | 50 - 200 µm (for extrusion-based) | Influences surface roughness, print time, and Z-axis mechanical properties. | Additive manufacturing standards |

| Filament Diameter (Extrusion) | 250 - 410 µm | Determines minimum achievable strut size and influences pore geometry. | Bioprinter specifications |

Table 2: Common Biomaterials & Their Properties for Scaffold Printing

| Material | Print Method | Key Properties | Research Application |

|---|---|---|---|

| Polycaprolactone (PCL) | Fused Deposition Modeling (FDM) | Biodegradable, good mechanical strength, slow degradation (2-3 years). | Ideal for long-term structural support in large defect models. |

| Tricalcium Phosphate (TCP) / HA Ceramics | Binder Jetting, Extrusion | Bioactive, osteoconductive, brittle. Mimics mineral content of bone. | Studying direct bone-binding (osseointegration) and composite materials. |

| PLA / PLGA | FDM, Stereolithography (SLA) | Tunable degradation rate (months to years), widely available. | Drug-eluting scaffold studies due to compatibility with various therapeutics. |

| Gelatin Methacrylate (GelMA) | Digital Light Processing (DLP), Extrusion | Photo-crosslinkable, cell-laden printing, supports cell viability. | In vitro models for cell-scaffold interaction and vascularization studies. |

Experimental Protocols

Protocol 2.1: DICOM Segmentation and 3D Model Generation for a Rabbit Calvarial Defect

Objective: To convert a micro-CT scan of a rabbit calvarial defect into a watertight 3D CAD model suitable for designing a fitting scaffold.

Materials & Software:

- Micro-CT DICOM dataset of rabbit skull with a critical-size defect.

- Workstation with 16+ GB RAM.

- Software: 3D Slicer (open-source), Mimics (Materialise), or similar.

Methodology:

- Import: Load the DICOM series into the segmentation software.

- Thresholding: Apply a global threshold based on Hounsfield Units (e.g., 250-2000 HU) to isolate bone tissue. Use the "paint" and "erase" tools to manually correct errors in the region of interest (ROI).

- Region of Interest (ROI) Isolation: Create a separate segmentation for the defect site. Use clipping planes to isolate the defect volume from the surrounding intact bone.

- 3D Model Generation: Use the "Create Surface" or "Calculate 3D" function on the defect segmentation. Set the smoothing parameter low (e.g., 5-15%) to preserve anatomical accuracy.

- Export: Export the generated 3D model as an STL (Stereolithography) file. Note the defect volume, which is typically calculated by the software (e.g., ~60 mm³ for an 8mm diameter calvarial defect).

Protocol 2.2: Design & Preparation of a Gyroid Lattice Scaffold for the Defect

Objective: To design a porous scaffold with a gyroid lattice structure that fits the defect geometry and is optimized for bone ingrowth.

Materials & Software:

- STL file of the defect (from Protocol 2.1).

- Software: nTopology, Autodesk Netfabb, or open-source Blender with CAD plugins.

Methodology:

- Boolean Subtraction: Import the defect STL as a "negative" mold. Create a solid block that is slightly larger than the defect.

- Lattice Implantation: Implant a gyroid lattice unit cell into the solid block. Set the unit cell size to achieve a target pore size of ~400 µm.

- Conformational Wrapping: Conform the lattice block to the exact geometry of the defect cavity using a Boolean intersection operation. This creates a scaffold that is anatomically accurate on its outer surface.

- Porosity & Strut Analysis: Use software tools to calculate the final scaffold porosity (target: ~70%) and average strut thickness (target: ~300-400 µm).

- Export for Printing: Export the final scaffold design as an STL file. Ensure the model is "watertight" (manifold) using repair tools.

Protocol 2.3: Slicing and FDM Printing of a PCL Scaffold

Objective: To fabricate the designed scaffold using fused deposition modeling (FDM) with medical-grade PCL.

Materials & Equipment:

- PCL filament (1.75 mm diameter, medical grade).

- FDM 3D Printer (e.g., Ultimaker, customized bioprinter) with a clean, heated build plate.

- Slicing software (e.g., Ultimaker Cura, PrusaSlicer).

Methodology:

- Slicing Parameters:

- Import the scaffold STL.

- Layer Height: 150 µm.

- Nozzle Diameter: 400 µm.

- Infill: 100% (pattern defined by the CAD model, not slicer).

- Printing Temperature: 80-100°C (PCL-specific).

- Build Plate Temperature: 40-60°C.

- Adhesion: Use a brim.

- Generate G-code.

- Printing:

- Load PCL filament, purge until clean extrusion.

- Start print in a controlled environment to minimize dust.

- Monitor first layers for adhesion.

- Post-Processing:

- Carefully remove the scaffold from the build plate.

- Support structures, if any, are typically not needed for lattice designs.

- Clean with compressed air or ethanol to remove debris.

- Sterilize via ethylene oxide (EtO) or gamma irradiation for in vitro/vivo studies.

Visualization: Workflow & Pathway Diagrams

Digital Workflow for 3D Printed Bone Scaffolds

Scaffold Properties Influence MSC Osteogenesis

The Scientist's Toolkit: Research Reagent & Material Solutions

Table 3: Essential Materials for Digital Workflow & Scaffold Testing

| Item | Function & Application in Research | Example Vendor / Specification |

|---|---|---|

| Micro-CT Scanner | High-resolution 3D imaging of bone defects and scaffold microstructure post-implantation. Essential for quantitative analysis of bone ingrowth (BV/TV). | Bruker Skyscan, Scanco Medical µCT 50 |

| Medical Image Processing Suite | Advanced segmentation, 3D reconstruction, and analysis of DICOM data. Critical for accurate defect modeling. | Materialise Mimics Innovation Suite, 3D Slicer (Open Source) |

| Generative Design Software | Creates complex, conformal lattice structures (gyroid, diamond) with controlled porosity within anatomical shapes. | nTopology, Autodesk Netfabb |

| Biocompatible PCL Filament | Standard material for FDM printing of resorbable scaffolds with consistent diameter and purity for in vivo studies. | 3D4Makers Medical PCL, Polymaker PolyDissolve S1 |

| Sterilization Pouch (EtO compatible) | For terminal sterilization of printed scaffolds prior to cell culture or animal implantation. | Steriking EtO Sterilization Bags |

| hMSC Growth Medium (Osteogenic) | Culture medium for differentiating human Mesenchymal Stem Cells on scaffolds, containing β-glycerophosphate, ascorbic acid, and dexamethasone. | ThermoFisher StemPro Osteogenesis Kit |

| AlamarBlue or PrestoBlue Assay | Resazurin-based assay for quantifying metabolic activity and proliferation of cells seeded on 3D scaffolds. | ThermoFisher, Invitrogen |

| Phalloidin (Actin Stain) & DAPI | Fluorescent stains for visualizing cell attachment, spreading, and cytoskeletal organization within the scaffold pores via confocal microscopy. | Sigma-Aldrich, Cytoskeleton, Inc. |

Application Notes

Incorporating bioactive agents into 3D-printed synthetic bone graft scaffolds is a pivotal strategy for enhancing osteoinductivity and preventing infection. Two primary loading strategies dominate: physical adsorption/soaking and incorporation during fabrication. Physical adsorption, post-printing, preserves bioactivity but offers uncontrolled burst release. Incorporation during fabrication, such as blending with bioinks or using coaxial printing, enables controlled release kinetics and spatial distribution but risks agent denaturation from processing conditions (e.g., shear stress, solvents). For antibiotics like gentamicin or vancomycin, direct blending is common. For sensitive growth factors like BMP-2, mild, aqueous post-printing soaking or affinity-based binding (e.g., via heparin) is often preferred. The choice depends on the agent's stability, desired release profile (immediate vs. sustained), and scaffold material (e.g., PCL, PLA, hydrogels).

Table 1: Quantitative Comparison of Primary Loading Strategies

| Strategy | Typical Loading Efficiency (%) | Initial Burst Release (0-24h) | Total Release Duration | Key Advantage | Key Limitation |

|---|---|---|---|---|---|

| Physical Adsorption (Soaking) | 60-85 | High (40-70%) | 3-10 days | Simple; preserves bioactivity | Uncontrolled burst release |

| Blend/Bioink Incorporation | 90-100 | Moderate (20-50%) | 1-4 weeks | Uniform distribution; tunable release | Potential bioactivity loss |

| Coaxial/Core-Shell Printing | 95-100 | Low (<20%) | 3-8 weeks | Excellent sustained release; protects agent | Technically complex |

| Affinity-Based Binding | 70-90 | Very Low (<10%) | 2-6 weeks | Sustained, biologically triggered release | Requires specific chemistry |

Table 2: Representative Agents & Common Loading Parameters

| Bioactive Agent | Typical Concentration Range | Common Carrier/Scaffold Material | Target Application |

|---|---|---|---|

| rhBMP-2 | 10-200 µg/mL | Collagen, HA, TCP, PLGA | Osteogenic differentiation |

| Gentamicin Sulfate | 1-10% (w/w polymer) | PCL, PLA, Calcium Sulfate | Prophylaxis against S. aureus |

| Vancomycin HCl | 2-15% (w/w polymer) | PCL, Bone Cement | MRSA infection treatment |

| VEGF | 5-50 µg/mL | GelMA, PEGDA hydrogels | Vascularization |

| Doxycycline | 1-5% (w/w polymer) | Chitosan, PCL | Anti-inflammatory & antimicrobial |

Protocols

Protocol 1: Post-Printing Adsorption of BMP-2 onto a PCL/HA Scaffold

Objective: To adsorb recombinant human BMP-2 (rhBMP-2) onto a 3D-printed PCL/hydroxyapatite composite scaffold to impart osteoinductivity. Materials: Sterile 3D-printed PCL/HA scaffold, rhBMP-2 lyophilized powder, 4 mM HCl (carrier), 0.1% BSA in PBS (loading buffer), sterile low-protein-binding tubes. Procedure:

- Solution Preparation: Reconstitute rhBMP-2 in 4 mM HCl to a stock concentration of 100 µg/mL. Dilute further in 0.1% BSA/PBS to the working concentration (e.g., 20 µg/mL).

- Loading: Place the sterile, dry scaffold in a sterile tube. Add the calculated volume of rhBMP-2 solution to fully submerge the scaffold (typically 100-200 µL per 50 mg scaffold).

- Incubation: Incubate at 4°C for 24 hours on an orbital shaker set to gentle agitation (50 rpm).

- Post-Loading: Carefully remove the scaffold. Rinse briefly (5 seconds) in PBS to remove surface-adherent protein. The scaffold is now ready for in vitro or in vivo use.

- Analysis: Determine loading efficiency by measuring rhBMP-2 concentration in the initial loading solution and the combined rinse/soak supernatant using an ELISA kit. Calculate: Loading Efficiency (%) = [(C_initial * V_initial) - (C_supernatant * V_supernatant)] / (C_initial * V_initial) * 100.

Protocol 2: Direct Blending and 3D Printing of Gentamicin-Loaded PCL Scaffolds

Objective: To fabricate a 3D-printed bone scaffold with sustained antibiotic release via melt extrusion printing. Materials: Medical-grade PCL pellets, gentamicin sulfate powder, twin-screw extruder, 3D melt extrusion printer (e.g., with heated nozzle), vacuum oven. Procedure:

- Blending: Dry blend PCL pellets with 5% (w/w) gentamicin sulfate powder.

- Extrusion: Feed the blend into a twin-screw extruder. Use a temperature profile of 80-100°C (below gentamicin degradation point). Extrude into filaments (diameter ~1.75 mm).

- Filament Conditioning: Dry the filaments in a vacuum oven at 40°C for 24 hours to remove moisture.

- 3D Printing: Load filament into the printer. Use a nozzle temperature of 100-110°C, bed temperature of 60°C, and a printing speed of 10-20 mm/s. Print the desired scaffold architecture (e.g., 0/90° laydown pattern, 300 µm pore size).

- Post-Processing: Sterilize scaffolds using low-temperature ethylene oxide or ethanol immersion.

- Release Kinetics Analysis: Immerse scaffolds (n=3) in PBS at 37°C under gentle agitation. Collect supernatant at predetermined times (1h, 4h, 1d, 3d, 7d, etc.). Analyze gentamicin concentration using a fluorescence polarization immunoassay or HPLC.

Protocol 3: Affinity-Based Loading of BMP-2 via Heparin Functionalization

Objective: To achieve sustained release of BMP-2 by exploiting its natural affinity for heparin. Materials: 3D-printed collagen or gelatin-based scaffold, 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC), N-hydroxysuccinimide (NHS), heparin, rhBMP-2, PBS. Procedure:

- Scaffold Functionalization: Activate carboxyl groups on the scaffold by immersing in a solution of 50 mM EDC and 25 mM NHS in MES buffer (pH 5.5) for 30 min. Rinse.

- Heparin Conjugation: Incubate the activated scaffold in a heparin solution (10 mg/mL in PBS, pH 7.4) for 24h at 4°C. Rinse thoroughly with PBS to remove unbound heparin.

- BMP-2 Loading: Incubate the heparinized scaffold in a rhBMP-2 solution (e.g., 30 µg/mL in PBS with 0.1% BSA) for 6h at room temperature.

- Rinsing & Storage: Rinse gently with PBS. Use immediately or lyophilize for storage at -20°C.

Visualizations

BMP-2 Osteogenic Signaling Pathway

Bioactive Agent Loading Strategy Decision Tree

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Loading Experiments

| Item | Function & Rationale | Example Product/Cat. No. |

|---|---|---|

| Recombinant Human BMP-2 | Gold-standard osteoinductive growth factor; induces osteoblast differentiation. | PeproTech, 120-02 |

| Gentamicin Sulfate | Broad-spectrum aminoglycoside antibiotic; used for infection prophylaxis in grafts. | Sigma-Aldrich, G1914 |

| Medical-Grade PCL | Biocompatible, biodegradable polyester for melt extrusion 3D printing. | Corbion, Purasorb PC 12 |

| Heparin Sodium Salt | Sulfated glycosaminoglycan; used for affinity-based growth factor delivery. | Sigma-Aldrich, H3149 |

| EDC Crosslinker | Carbodiimide crosslinker for conjugating carboxyl to amine groups (e.g., heparin). | Thermo Fisher, 22980 |

| BSA (Fraction V) | Used as a carrier protein in loading buffers to prevent non-specific adhesion/denaturation. | Sigma-Aldrich, A7906 |

| rhBMP-2 ELISA Kit | Quantifies BMP-2 concentration for loading efficiency and release kinetics. | R&D Systems, DBP200 |

| Gentamicin ELISA/FPIA Kit | Quantifies gentamicin concentration in release studies. | Abcam, ab269538 |

Within the research for 3D printing of synthetic bone graft scaffolds, post-processing is a critical determinant of final scaffold performance. This document provides detailed application notes and protocols for three pivotal post-fabrication stages: sintering to achieve mechanical integrity, surface functionalization to enhance bioactivity, and terminal sterilization for clinical translation. These protocols are designed for researchers, scientists, and drug development professionals working with bioceramics (e.g., hydroxyapatite, β-tricalcium phosphate) and biocompatible polymers.

Sintering Protocols for Mechanical Consolidation

Sintering thermally consolidates printed green bodies, densifying the material and establishing mechanical strength.

Protocol: Two-Stage Sintering (TSS) for Hydroxyapatite Scaffolds

Principle: TSS suppresses final-stage grain growth while achieving high density, optimizing the strength-porosity trade-off. Materials: 3D printed HA scaffold (green body), high-temperature furnace with programmable controller, alumina crucible. Procedure:

- Debinding: Heat at 2°C/min to 600°C; hold for 2 hours to remove organic binders.

- First Sintering Stage: Increase temperature at 5°C/min to T1 (e.g., 1050°C). Hold for 5 minutes.

- Second Sintering Stage: Immediately lower furnace temperature to T2 (e.g., 950°C). Hold for 10 hours.

- Cooling: Allow furnace to cool to room temperature at a controlled rate of 3°C/min. Note: T1 and T2 require empirical optimization based on powder particle size and desired porosity.

Quantitative Sintering Data

Table 1: Effect of Sintering Parameters on Scaffold Properties

| Material | Sintering Protocol | Final Density (% Theoretical) | Compressive Strength (MPa) | Average Pore Size (µm) | Reference Year |

|---|---|---|---|---|---|

| β-TCP | Conventional: 1250°C, 2h | 92.5% | 12.3 ± 1.5 | 320 ± 50 | 2023 |

| β-TCP | TSS: 1150°C→1050°C, 10h | 95.1% | 18.7 ± 2.1 | 280 ± 40 | 2023 |

| HA | Microwave: 1100°C, 30 min | 88.0% | 9.8 ± 1.2 | 400 ± 60 | 2024 |

| HA/ZrO2 | Conventional: 1350°C, 4h | 96.8% | 42.5 ± 3.8 | 150 ± 30 | 2024 |

Title: Two-Stage Sintering Thermal Workflow

Surface Functionalization for Enhanced Bioactivity

Functionalization introduces biochemical cues to promote osteoconduction and osteoinduction.

Protocol: Polydopamine-Assisted Immobilization of BMP-2 Peptide

Principle: Polydopamine (PDA) forms an adherent, reactive coating on various materials, enabling covalent peptide immobilization. Materials: Sintered scaffold, dopamine hydrochloride, Tris buffer (10 mM, pH 8.5), BMP-2 mimetic peptide (e.g., KPQKP), EDC/NHS coupling reagents. Procedure:

- PDA Coating: Immerse scaffold in 2 mg/mL dopamine solution in Tris buffer. Agitate gently for 24 hours at room temperature. Rinse thoroughly with deionized water.

- Activation: Prepare a 50 mM MES buffer (pH 5.5) containing 2 mM EDC and 5 mM NHS. Immerse PDA-coated scaffold for 30 minutes. Rinse.

- Peptide Coupling: Immerse scaffold in a 100 µg/mL solution of BMP-2 peptide in PBS (pH 7.4). Incubate at 4°C for 12 hours.

- Quenching & Rinsing: Rinse with PBS containing 0.1% Tween-20, then pure PBS. Store sterile.

Quantitative Functionalization Data

Table 2: Efficacy of Surface Functionalization Methods

| Functionalization Method | Coating Thickness (nm) | Peptide Density (pmol/cm²) | In Vitro Osteogenic Marker (ALP Activity, % Increase vs Control) | Reference Year |

|---|---|---|---|---|

| Polydopamine + BMP-2 Peptide | 25 ± 5 | 12.3 ± 1.8 | 245% | 2024 |

| Silk Fibroin Coating | 5000 ± 1000 | N/A | 180% | 2023 |

| Plasma Treatment + RGD Grafting | <5 | 8.7 ± 0.9 | 165% | 2023 |

| Layer-by-Layer (Chi/HA) | 100 ± 20 | N/A | 190% | 2024 |

Title: Polydopamine-Mediated Peptide Immobilization Pathway

Sterilization Methods for Clinical Readiness

Sterilization must eliminate bioburden without degrading scaffold properties.

Protocol: Low-Temperature Hydrogen Peroxide Plasma (H2O2 Plasma) Sterilization

Principle: H2O2 vapor diffuses into pores, followed by plasma phase generating reactive species that lethally oxidize microorganisms at low temperature. Materials: Sterrad or similar H2O2 plasma system, Tyvek pouches, biological indicators (Geobacillus stearothermophilus). Pre-Sterilization: Dry scaffolds completely in a desiccator. Procedure:

- Packaging: Place scaffold in a Tyvek pouch. Seal.

- Loading: Place pouch in sterilizer chamber, ensuring no overcrowding.

- Cycle: Run standard "Low-Temperature" cycle (approx. 55°C, 1-3 hours, depending on load).

- Verification: Process biological indicator and incubate per manufacturer's instructions to confirm sterility.

Quantitative Sterilization Data

Table 3: Impact of Sterilization Methods on Scaffold Properties

| Sterilization Method | Temperature | Efficacy (Log Reduction) | Compressive Strength Retention | Bioactivity Retention (ALP) | Reference Year |

|---|---|---|---|---|---|

| Autoclave (121°C) | High | >6 | 85% | 70% | 2023 |

| Ethylene Oxide (EtO) | Low (~37°C) | >6 | 98% | 95% | 2024 |

| H2O2 Plasma (Sterrad) | Low (~55°C) | >6 | 99% | 98% | 2024 |

| Gamma Irradiation (25 kGy) | Ambient | >6 | 92% | 90% | 2023 |

Title: Sterilization Method Decision Logic

The Scientist's Toolkit

Table 4: Key Research Reagent Solutions for Post-Processing

| Item | Function in Protocols | Example Product/Catalog |

|---|---|---|

| Dopamine Hydrochloride | Precursor for universal polydopamine coating for surface functionalization. | Sigma-Aldrich, H8502 |

| EDC (1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide) | Carboxyl activating agent for peptide coupling. | Thermo Fisher, 22980 |

| Sulfo-NHS (N-Hydroxysulfosuccinimide) | Stabilizes amine-reactive intermediates, improving coupling efficiency. | Thermo Fisher, 24510 |

| BMP-2 Mimetic Peptide (KPQKP) | Short peptide sequence inducing osteogenic differentiation. | PeproTech, BP-2M |

| Biological Indicators (G. stearothermophilus) | Validates sterilization process efficacy. | MesaLabs, BI-220 |

| Tris Buffer (pH 8.5) | Alkaline buffer for optimal polydopamine polymerization. | Various |

| MES Buffer (pH 5.5) | Optimal pH buffer for EDC/NHS carboxyl activation. | Various |

| Alumina Crucibles | Inert containers for high-temperature scaffold sintering. | CoorsTek, 60001 |

Within the broader thesis on 3D-printed synthetic bone graft scaffolds, the integration of vascular networks remains the paramount challenge for clinical translation. This protocol focuses on the fabrication of vascularized bone constructs using extrusion-based bioprinting with a dual-bioink strategy, co-printing osteogenic and angiogenic cell-laden hydrogels. The approach aims to create prevascularized networks in vitro that can anastomose with the host vasculature in vivo, enhancing graft survival and bone regeneration.

Key Application Notes:

- Objective: To generate a mechanically stable, osteogenic construct with embedded, perfusable endothelial networks.

- Challenge Addressed: Overcoming diffusion limits (~200 µm) in large scaffolds to prevent necrotic cores.

- Strategy: Simultaneous printing of a cell-laden gelatin methacryloyl (GelMA)/alginate composite bioink (for bone) and a sacrificial pluronic F-127 bioink (for vascular channels).

- Post-Printing: In vitro maturation under osteogenic and angiogenic culture conditions with dynamic perfusion to enhance network formation and matrix deposition.

Experimental Protocols

Protocol 1: Bioink Preparation & Cell Encapsulation

- Materials: See Scientist's Toolkit.

- Osteogenic Bioink (GelMA/Alginate):

- Sterilize 10% (w/v) GelMA (degree of substitution ~80%) and 3% (w/v) alginate solutions by filtration (0.22 µm).

- Mix GelMA and alginate at a 7:3 volume ratio. Add 0.1% (w/v) photoinitiator LAP.

- Trypsinize and centrifuge human mesenchymal stem cells (hMSCs). Resuspend cell pellet in bioink to a final density of 5 x 10^6 cells/mL. Keep on ice.

- Angiogenic Bioink & Sacrificial Ink:

- For angiogenic bioink, mix human umbilical vein endothelial cells (HUVECs, 1 x 10^7 cells/mL) with the same GelMA/alginate blend. Add 0.5 x 10^6 cells/mL normal human dermal fibroblasts (NHDFs) as supporting pericytes.

- For sacrificial ink, prepare 25% (w/v) Pluronic F-127 in sterile, cold cell culture medium.

Protocol 2: Dual-Nozzle Bioprinting Process

- Printer Setup: Sterilize print bed and nozzles (22G, tapered) with 70% ethanol and UV light. Maintain print chamber at 15°C.

- Printing Parameters:

- Pressure: 25-30 kPa for cell-laden bioinks, 15-20 kPa for Pluronic.

- Speed: 8 mm/s.

- Nozzle Temperature: 15°C.

- Bed Temperature: 4°C.

- Printing Sequence:

- Load osteogenic bioink into syringe A. Load sacrificial Pluronic F-127 into syringe B.

- Print a 15 x 15 mm grid structure (layer height 0.3 mm). First layer: Osteogenic bioink. Second layer: Print Pluronic F-127 lines within the osteogenic matrix to create channel patterns.

- Repeat for 10 layers. After every two layers, crosslink the structure with a 365 nm UV light (5 mW/cm², 60 seconds).

- Post-Printing Sacrifice: Submerge the printed construct in cold (4°C) culture medium for 30 minutes to liquefy and remove the Pluronic, leaving behind patent microchannels.

Protocol 3: In Vitro Maturation & Perfusion Culture

- Seed the lumen of the created channels with HUVECs (2 x 10^6 cells/mL in EGM-2 medium) by pipetting the cell suspension into the channels.

- Transfer construct to a bioreactor chamber. Culture in a 1:1 mix of osteogenic medium (for hMSCs) and EGM-2 medium (for HUVECs) for the first 3 days.

- On day 4, initiate dynamic perfusion using a peristaltic pump (shear stress ~0.5 dyn/cm², 0.2 mL/min).