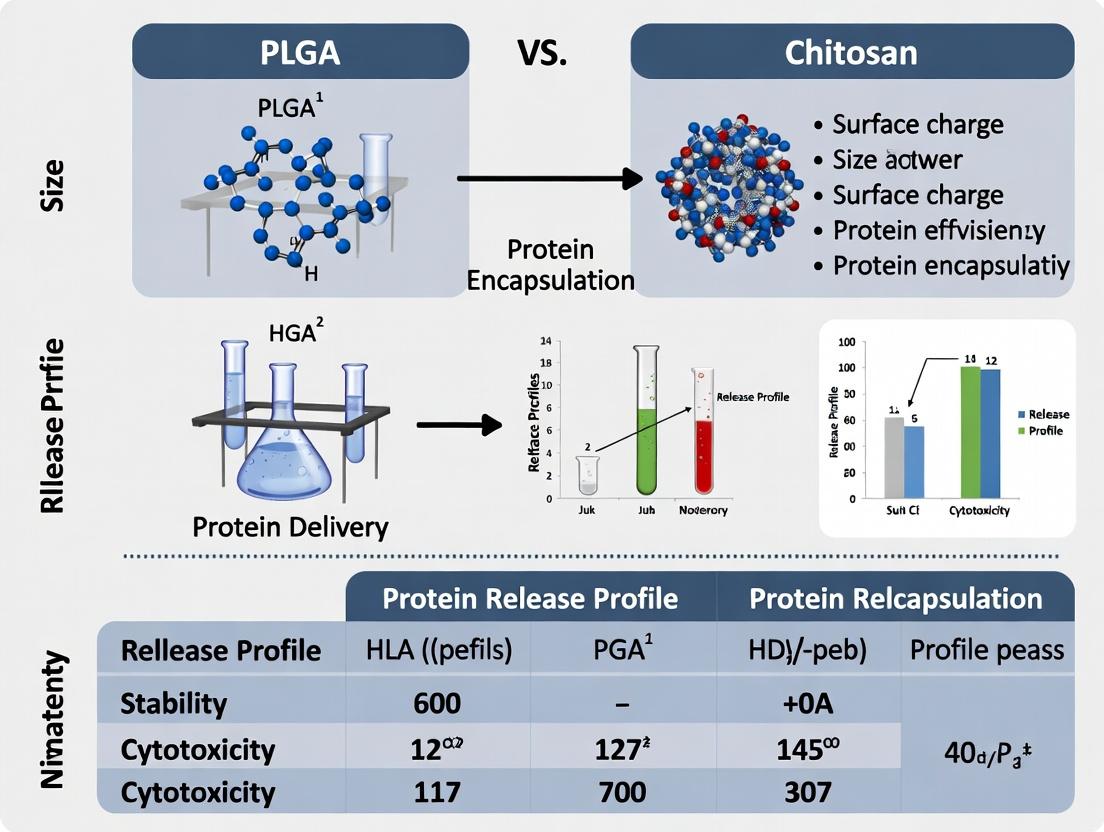

PLGA vs. Chitosan Nanoparticles: A Comparative Analysis for Protein Drug Delivery Systems

This comprehensive review analyzes PLGA and chitosan nanoparticles as leading platforms for protein delivery, addressing formulation, stability, efficacy, and clinical translation.

PLGA vs. Chitosan Nanoparticles: A Comparative Analysis for Protein Drug Delivery Systems

Abstract

This comprehensive review analyzes PLGA and chitosan nanoparticles as leading platforms for protein delivery, addressing formulation, stability, efficacy, and clinical translation. Tailored for researchers and pharmaceutical scientists, it provides a structured comparison of their material properties, synthesis methodologies, optimization strategies, and comparative performance metrics to inform rational nanocarrier selection for therapeutic proteins.

Core Biopolymer Platforms: Understanding PLGA and Chitosan for Nanomedicine

Nanoparticle-based delivery systems offer a promising strategy to overcome the inherent challenges of delivering therapeutic proteins, which include poor stability, rapid clearance, and limited cellular uptake. This guide provides a comparative analysis of two leading polymeric nanoparticle platforms—poly(lactic-co-glycolic acid) (PLGA) and chitosan—within the context of protein delivery research. The comparison is grounded in recent experimental data, focusing on key performance parameters critical for research and development.

Comparison Guide: PLGA vs. Chitosan Nanoparticles for Protein Delivery

The following table summarizes a synthesis of recent findings comparing the performance of PLGA and chitosan nanoparticles in protein delivery applications.

Table 1: Comparative Performance of PLGA and Chitosan Nanoparticles

| Performance Parameter | PLGA Nanoparticles | Chitosan Nanoparticles | Experimental Basis |

|---|---|---|---|

| Typical Encapsulation Efficiency (EE%) | 45-75% for BSA | 55-85% for BSA | Double emulsion/solvent evaporation for PLGA; Ionic gelation for chitosan. |

| In Vitro Release Profile (PBS, pH 7.4) | Biphasic: ~20-30% burst release in 24h, sustained release over 7-28 days. | Monophasic: ~40-60% release within 24h, often complete within 3-5 days. | Dialysis method; Cumulative release measured via micro-BCA assay. |

| Mucoadhesive Potential | Low to moderate. | High, due to positive charge interacting with negatively charged mucosal surfaces. | Ex vivo mucosal adhesion test using intestinal tissue; chitosan shows 2-3x higher adhesion. |

| Cellular Uptake Efficiency (in Caco-2 cells) | Moderate. Depends on surface PEGylation. | High, facilitated by electrostatic interaction with negatively charged cell membranes. | Flow cytometry of cells treated with FITC-labeled nanoparticles; chitosan uptake often 1.5-2x higher. |

| Primary Stability Challenge | Acidic microclimate degradation during polymer erosion can compromise protein integrity. | Swelling and rapid release in neutral/alkaline pH environments. | Stability assessed via SDS-PAGE and ELISA after incubation in simulated gastric/intestinal fluids. |

| Key Functional Advantage | Excellent control over sustained release kinetics; FDA-approved polymer history. | Enhanced permeation across mucosal/epithelial barriers; intrinsic bioadhesion. |

Experimental Protocols for Key Cited Data

Protocol 1: Preparation and In Vitro Release Testing

- PLGA Nanoparticles (Double Emulsion - W/O/W): Dissolve PLGA (50:50, 10 mg) in dichloromethane (DCM). Add primary aqueous phase (100 µL containing 1 mg model protein, e.g., BSA). Sonicate to form primary W/O emulsion. This emulsion is poured into 2 mL of polyvinyl alcohol (PVA, 2% w/v) and sonicated to form the W/O/W double emulsion. Stir overnight to evaporate DCM, collect by centrifugation, wash, and lyophilize.

- Chitosan Nanoparticles (Ionic Gelation): Dissolve chitosan (2 mg/mL) in acetic acid (1% v/v, pH ~4.5). Dissolve model protein (1 mg/mL) in the chitosan solution. Under magnetic stirring, add sodium tripolyphosphate (TPP, 1 mg/mL) solution dropwise (chitosan:TPP volume ratio 5:1). Nanoparticles form spontaneously. Stir for 30 min, collect by centrifugation, wash, and resuspend.

- Release Study: Place nanoparticle pellet (containing ~0.5 mg protein) in a dialysis bag (MWCO 100 kDa). Immerse in phosphate buffer saline (PBS, pH 7.4, 10 mL) at 37°C with gentle shaking. At predetermined intervals, withdraw and replace the entire external buffer. Analyze protein content in the aliquot using a micro-BCA protein assay.

Protocol 2: Cellular Uptake Assay (Flow Cytometry)

- Nanoparticle Labeling: Prepare nanoparticles encapsulating FITC-BSA instead of native BSA using the above protocols.

- Cell Culture: Seed Caco-2 cells in 12-well plates at 2 x 10^5 cells/well and culture until ~80% confluent.

- Treatment & Incubation: Treat cells with FITC-labeled nanoparticles (equivalent to 10 µg/mL FITC-BSA) in serum-free medium. Incubate for 2-4 hours at 37°C.

- Analysis: Wash cells with cold PBS, trypsinize, and resuspend in PBS containing 1% BSA. Analyze cellular fluorescence immediately using a flow cytometer (excitation 488 nm, emission 530/30 nm). Use untreated cells as a negative control. Express results as mean fluorescence intensity (MFI) or percentage of FITC-positive cells.

Visualizing the Experimental Workflow and Key Mechanism

Diagram 1: Synthesis & Uptake Pathways for PLGA vs. Chitosan NPs

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Nanoparticle Protein Delivery Research

| Reagent/Material | Function & Role in Research | Example Vendor/Product |

|---|---|---|

| PLGA (50:50, acid-terminated) | The biodegradable polymer backbone for forming sustained-release nanoparticles. Molecular weight (e.g., 7-17 kDa, 24-38 kDa) controls degradation rate. | Lactel Absorbable Polymers (DURECT), Sigma-Aldrich |

| Medium Molecular Weight Chitosan | The cationic, mucoadhesive polymer that forms nanoparticles via ionic crosslinking. Degree of deacetylation (>75%) impacts solubility and charge density. | Sigma-Aldrich, NovaMatrix |

| Model Protein (e.g., BSA, FITC-BSA, Lysozyme) | A stable, well-characterized protein used to standardize encapsulation, release, and uptake experiments without the cost of therapeutics. | Sigma-Aldrich |

| Polyvinyl Alcohol (PVA, 87-89% hydrolyzed) | Critical surfactant used in the formulation of PLGA nanoparticles via emulsification methods to stabilize droplets and control particle size. | Sigma-Aldrich |

| Sodium Tripolyphosphate (TPP) | Ionic crosslinker used to gel chitosan via electrostatic interaction between NH₃⁺ groups of chitosan and phosphate groups of TPP. | Sigma-Aldrich |

| Micro-BCA Protein Assay Kit | Highly sensitive colorimetric method for quantifying low concentrations of protein in release supernatants and encapsulation studies. | Thermo Fisher Scientific |

| Dialysis Membranes (MWCO 100 kDa) | Used for in vitro release studies; allows diffusion of released protein while retaining nanoparticles inside the bag. | Spectra/Por (Repligen) |

| Caco-2 Cell Line | A widely used in vitro model of human intestinal epithelium for assessing nanoparticle permeability, transport, and cellular uptake. | ATCC |

Within the ongoing research thesis comparing PLGA and chitosan nanoparticles for protein delivery, a comprehensive understanding of PLGA's synthesis, degradation behavior, and regulatory standing is fundamental. This guide objectively compares these facets of PLGA against relevant alternatives, primarily chitosan, supported by experimental data.

Synthesis: Comparison of PLGA vs. Chitosan Nanoparticle Fabrication

The synthesis routes for PLGA and chitosan nanoparticles differ significantly, impacting particle characteristics and suitability for protein encapsulation.

Table 1: Comparison of Common Synthesis Methods for Protein-Loaded Nanoparticles

| Synthesis Parameter | PLGA Nanoparticles | Chitosan Nanoparticles | Experimental Implication |

|---|---|---|---|

| Primary Method | Double Emulsion (W/O/W) | Ionic Gelation (Tripolyphosphate/TPP) | PLGA method is more complex, often requiring energy input (sonication). |

| Organic Solvent Required | Yes (e.g., Dichloromethane, Ethyl Acetate) | Typically No (Aqueous-based) | Solvent residue in PLGA is a regulatory concern; chitosan process is greener. |

| Protein Encapsulation Efficiency (EE%) | 40-70% (for hydrophilic proteins) | 50-80% (highly dependent on protein pI) | Both can achieve moderate EE; chitosan can show higher EE for positively charged proteins. |

| Particle Size Range (typical) | 150-300 nm | 100-250 nm | Both can be tuned to sub-300nm ranges suitable for cellular uptake. |

| Surface Charge (Zeta Potential) | Negative to slightly negative (-5 to -20 mV) | Positive (+20 to +60 mV) | Key differentiator: Chitosan's positive charge promotes mucoadhesion and may enhance uptake across negatively charged mucosal membranes. |

Experimental Protocol: Double Emulsion (W/O/W) for PLGA Nanoparticles

Objective: To encapsulate a model protein (e.g., Bovine Serum Albumin - BSA) in PLGA nanoparticles.

- Primary Emulsion: Dissolve 100 mg PLGA (50:50 LA:GA) in 2 mL dichloromethane (DCM). Add 200 µL of an aqueous BSA solution (10 mg/mL) to the organic phase. Probe sonicate on ice for 60 seconds (30% amplitude) to form a water-in-oil (W/O) emulsion.

- Secondary Emulsion: Quickly pour the primary emulsion into 8 mL of an aqueous polyvinyl alcohol (PVA) solution (2% w/v). Probe sonicate on ice for 90 seconds to form a (W/O)/W double emulsion.

- Solvent Evaporation: Stir the double emulsion magnetically at room temperature for 4 hours to evaporate DCM.

- Purification: Centrifuge the nanoparticle suspension at 20,000 x g for 30 minutes. Wash the pellet with distilled water and repeat centrifugation. Resuspend in buffer for characterization.

- Characterization: Measure particle size and zeta potential via dynamic light scattering. Determine BSA encapsulation efficiency using a microBCA assay on the supernatant and washed fractions.

Degradation Profile: PLGA vs. Chitosan Hydrolysis

The degradation mechanism and timeline are critical for controlled protein release.

Table 2: Comparative Degradation Profiles of PLGA and Chitosan

| Degradation Aspect | PLGA | Chitosan | Supporting Experimental Data |

|---|---|---|---|

| Primary Mechanism | Bulk hydrolysis of ester bonds. | Enzymatic (lysozyme) degradation and acid-catalyzed hydrolysis. | In vitro mass loss studies show PLGA degrades in a predictable sigmoidal pattern, while chitosan degradation rate varies with degree of deacetylation and enzyme presence. |

| Degradation Timeframe | Weeks to months (tunable by LA:GA ratio, MW). | Hours to days (for low MW); weeks (for high MW/cross-linked). | PLGA (50:50, IV~0.6 dL/g): ~50% mass loss in 4-6 weeks in PBS (pH 7.4, 37°C). Chitosan (90% DDA): ~80% mass loss in 3 weeks in 1 mg/mL lysozyme/PBS. |

| Degradation By-products | Lactic acid and glycolic acid (metabolized via Krebs cycle). | D-glucosamine and N-acetyl-D-glucosamine (non-toxic, biocompatible). | pH drop in microenvironment is more pronounced for PLGA due to acid accumulation, which can risk protein stability. Chitosan degradation does not significantly lower pH. |

| Influence on Protein Release Kinetics | Tri-phasic: initial burst, diffusion-controlled, then degradation-controlled release. | Typically bi-phasic: initial burst followed by erosion-controlled release. | For BSA, PLGA often shows a 20-30% burst release within 24h, followed by sustained release over 28+ days. Chitosan shows a 25-40% burst, with complete release often within 3-7 days unless highly cross-linked. |

PLGA Degradation Pathway Overview

Experimental Protocol:In VitroDegradation and Release Study

Objective: To monitor mass loss and protein release from PLGA and chitosan nanoparticles.

- Sample Preparation: Precisely weigh 20 mg of freeze-dried, protein-loaded nanoparticles (n=5 per time point). Place each aliquot in a microcentrifuge tube with 1.5 mL phosphate-buffered saline (PBS, pH 7.4) containing 0.02% sodium azide. For chitosan, include a parallel set with 1 mg/mL lysozyme.

- Incubation: Place tubes in an orbital shaker incubator at 37°C, 100 rpm.

- Sampling: At predetermined intervals (e.g., days 1, 3, 7, 14, 28), remove one set of tubes (n=5).

- Mass Loss Analysis: Centrifuge samples. Carefully remove supernatant (save for release analysis). Wash pellet with water, freeze-dry, and weigh dry mass. Calculate percentage mass remaining.

- Protein Release Analysis: Quantify protein concentration in the saved supernatant using a spectrophotometric assay (e.g., microBCA). Calculate cumulative release as a percentage of total encapsulated protein.

Regulatory Status: PLGA vs. Chitosan

Regulatory acceptance is a decisive factor for clinical translation.

Table 3: Regulatory and Safety Comparison for Drug Delivery

| Regulatory Aspect | PLGA | Chitosan | Key Notes |

|---|---|---|---|

| US FDA Status | Extensive history in approved products (e.g., Lupron Depot, Zoladex). Components (LA, GA) are GRAS. | FDA-approved for wound dressings and dietary supplements. As a drug delivery excipient, it is subject to New Drug Application (NDA) review. | PLGA has a more straightforward regulatory path for parenteral depot formulations. Chitosan requires full safety data per application. |

| EMA Status | Approved in numerous medicinal products. Listed as a well-established excipient. | Not included in the "well-established" list. Requires more comprehensive documentation. | Similar to FDA, PLGA is preferred in EU for established delivery platforms. |

| Toxicity Profile | Excellent biocompatibility and safety. Degradation products are endogenous metabolites. | Generally recognized as safe, but potential for allergic reactions (shellfish origin). Purity and endotoxin levels are critical. | Both are considered safe, but PLGA's synthetic origin offers more batch-to-batch consistency. |

| Key Regulatory Hurdle | Control of residual solvents from synthesis. | Demonstration of consistent polymer characteristics (MW, DDA) and absence of immunogenic contaminants. | For both, a well-defined Chemistry, Manufacturing, and Controls (CMC) section is vital. |

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for PLGA/Chitosan Protein Delivery Research

| Item | Function & Importance | Example Supplier/Product |

|---|---|---|

| PLGA (50:50 LA:GA) | The core biodegradable polymer. Ratio determines degradation rate and release profile. | Lactel Absorbable Polymers (DURECT Corporation), Evonik (RESOMER RG 502H). |

| Medium MW Chitosan | The cationic natural polymer. Degree of deacetylation (DDA) affects charge, solubility, and degradation. | Sigma-Aldrich (Product #448877, ~85% DDA), NovaMatrix (Chitoce). |

| Polyvinyl Alcohol (PVA) | Critical surfactant/stabilizer in PLGA double emulsion synthesis. Affects particle size and surface properties. | Sigma-Aldrich (87-90% hydrolyzed, Mw 30-70 kDa). |

| Sodium Tripolyphosphate (TPP) | Ionic cross-linker for forming chitosan nanoparticles via ionic gelation. | Sigma-Aldrich (Product #72059). |

| Dichloromethane (DCM) | Common organic solvent for dissolving PLGA. Requires careful control of residual levels. | High purity, HPLC grade from any major chemical supplier. |

| Lysozyme | Enzyme used to simulate in vivo degradation of chitosan nanoparticles in bio-relevant media. | Sigma-Aldrich (Product #L6876). |

| Micro BCA Protein Assay Kit | Sensitive spectrophotometric assay for quantifying low levels of protein in encapsulation and release studies. | Thermo Fisher Scientific (Product #23235). |

Chitosan, a linear polysaccharide derived from the deacetylation of chitin, is a cornerstone material in advanced drug delivery systems. Its cationic nature, biodegradability, and biocompatibility make it a prime candidate for mucosal drug delivery. This guide objectively compares the performance of chitosan-based nanoparticles, particularly against synthetic polymers like Poly(lactic-co-glycolic acid) (PLGA), within a thesis framework focused on protein delivery. A critical advantage of chitosan is its innate mucoadhesive property, which arises from electrostatic interactions between its protonated amino groups and the negatively charged sialic acid residues in mucosal glycoproteins.

Source and Chemical Derivatization of Chitosan

Chitosan is sourced from chitin, the second most abundant natural polymer after cellulose, found in crustacean shells (crabs, shrimp), insect exoskeletons, and fungal cell walls. The degree of deacetylation (DD, typically >60%) and molecular weight are primary determinants of its properties.

Common chemical derivatizations to enhance solubility, mucoadhesion, or targeting include:

- Quaternary Ammonium Chitosan: Permanently cationic, enhancing solubility at neutral pH and mucoadhesion.

- Carboxymethyl Chitosan: Anionic derivative with improved water solubility.

- Thiolated Chitosan (Chitosan-TBA, Chitosan–glutathione conjugates): Forms disulfide bonds with cysteine-rich subdomains of mucus glycoproteins, drastically increasing mucoadhesion via covalent bonds.

- PEGylated Chitosan: Improves nanoparticle stability and circulation time by imparting steric hindrance.

Performance Comparison: Chitosan vs. PLGA Nanoparticles for Protein Delivery

The following tables summarize key comparative performance metrics based on recent experimental studies.

Table 1: Core Material and Formulation Properties

| Property | Chitosan (CS) Nanoparticles | PLGA Nanoparticles | Experimental Measurement Method |

|---|---|---|---|

| Surface Charge | Strongly positive (+20 to +60 mV) | Negative or slightly negative (-20 to -10 mV) | Zeta potential analyzer (dynamic light scattering). |

| Mucoadhesive Strength | Very High | Low to Moderate | Ex vivo wash-off tests using intestinal/mucosal tissue; rheological synergy measurement. |

| Interaction with Mucus | Electrostatic, can penetrate mucus layer. | Primarily hydrophobic, often mucoinert or trapped. | Multiple particle tracking (MPT) to measure microtransport rates. |

| Protein Loading Efficiency | Moderate to High (60-85%) | High (70-90%) | UV-Vis/BCA assay of supernatant post-formulation. |

| Primary Encapsulation Method | Ionic gelation (with TPP), polyelectrolyte complexation. | Double emulsion (W/O/W), nanoprecipitation. | Varies by method. |

Table 2: Functional Performance in Protein Delivery

| Performance Metric | Chitosan Nanoparticles | PLGA Nanoparticles | Supporting Experimental Data Summary |

|---|---|---|---|

| Mucosal Residence Time | ~4-6 hours (significant increase vs. solution) | ~1-2 hours (moderate increase) | In vivo fluorescence imaging in rodents showed CS-NPs retained at intestinal mucosa 3x longer than PLGA-NPs. |

| Protein Release Profile | Burst release followed by sustained release (up to 48-72 hrs). | Tri-phasic: burst, lag, sustained release (days to weeks). | In vitro release in PBS (pH 7.4): CS-NPs released 60-80% of BSA by 48h; PLGA released <30% by 48h, with full release over 3 weeks. |

| Permeation Enhancement | High (opens tight junctions via charge interaction). | Low (relies on particle uptake). | Apparent permeability coefficient (Papp) of insulin across Caco-2 monolayers increased 5-8 fold for CS-NPs vs. 2-3 fold for PLGA. |

| Protein Stability Post-Encapsulation | Risk of aggregation at low pH during formulation. | Risk of denaturation at organic-aqueous interfaces. | FTIR/CD spectroscopy: CS-complexed lysozyme retained ~85% native structure; PLGA-encapsulated retained ~70%. |

Experimental Protocols for Key Comparisons

Protocol 1: Ex Vivo Mucoadhesion Wash-Off Test

- Tissue Preparation: Excise a section of fresh porcine intestinal mucosa and mount on a slanted platform (45°) in a humidity chamber at 37°C.

- Nanoparticle Application: Apply 1 mL of fluorescently labeled nanoparticle suspension (CS or PLGA) evenly onto the mucosal surface.

- Simulated Mucus Flow: Continuously perfuse the tissue with simulated intestinal fluid (SIF, pH 6.8) at a constant rate (e.g., 1 mL/min).

- Quantification: Collect perfusate at fixed time intervals (e.g., every 15 min for 2 hours). Measure fluorescence intensity in the perfusate to determine the percentage of nanoparticles retained on the tissue over time.

Protocol 2: Multiple Particle Tracking (MPT) for Mucus Permeability

- Sample Preparation: Mix a dilute suspension of nanoparticles (labeled with 200 nm red fluorescent beads) with freshly harvested human or synthetic mucus.

- Imaging: Place sample on a microscope slide and record high-speed video (100 frames/sec) using a fluorescence microscope with a high NA objective.

- Tracking & Analysis: Use tracking software (e.g., ImageJ with Mosaic plug-in) to trace the mean squared displacement (MSD) of hundreds of individual particles over time.

- Calculation: Calculate the geometric mean of the diffusivity coefficients for each nanoparticle formulation. A higher MSD and diffusivity indicate better mucus-penetrating capability.

Protocol 3: In Vitro Protein Release and Stability Assessment

- Release Study: Place a known amount of protein-loaded nanoparticles in a dialysis bag (MWCO 100 kDa). Immerse in release medium (PBS with 0.02% Tween 80, pH 7.4) under gentle agitation at 37°C.

- Sampling: Withdraw aliquots from the external medium at predetermined times and replace with fresh medium.

- Protein Quantification: Quantify released protein using a stability-indicating assay (e.g., reverse-phase HPLC for insulin, BCA for BSA).

- Stability Analysis: Recover nanoparticles from the dialysis bag at the study endpoint. Lyse particles (for PLGA: dissolve in DMSO/NaOH; for CS: dissolve in acidic medium). Analyze protein integrity via Circular Dichroism (CD) spectroscopy and SDS-PAGE.

Visualizations

Diagram 1: Chitosan from source to common derivatives.

Diagram 2: Chitosan mucoadhesion mechanism and effects.

Diagram 3: Ionic gelation for chitosan nanoparticles.

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Chitosan Nanoparticle Research |

|---|---|

| Low/Medium Molecular Weight Chitosan (DD > 75%) | The primary polymer for nanoparticle formation; properties vary with MW and DD. |

| Sodium Tripolyphosphate (TPP) | Ionic crosslinker used in the simple ionotropic gelation method to form NPs. |

| N-Acetyl Cysteine (NAC) / Thioglycolic Acid (TGA) | Thiolating agents used to synthesize thiolated chitosan for superior mucoadhesion. |

| Glycidyl Trimethyl Ammonium Chloride (GTMAC) | Quaternary agent used to synthesize permanently cationic, pH-independent chitosan. |

| Fluorescein Isothiocyanate (FITC) / Rhodamine B | Fluorescent dyes for labeling chitosan or proteins for tracking and visualization studies. |

| Simulated Intestinal Fluid (SIF, pH 6.8) | Standard medium for in vitro release and mucoadhesion testing under physiological conditions. |

| Mucin (Type II, from porcine stomach) | Key glycoprotein used to create in vitro mucus models for penetration and binding studies. |

| Caco-2/HT29-MTX Co-culture Cells | Gold-standard in vitro intestinal barrier model for permeability and toxicity studies. |

In the pursuit of effective protein nanocarriers, PLGA (poly(lactic-co-glycolic acid)) and chitosan nanoparticles represent two dominant paradigms. Their fundamental biophysical properties—molecular weight (MW), charge, and hydrophobicity—directly dictate protein loading, release kinetics, stability, and cellular interactions. This guide provides an objective comparison of these properties, supported by experimental data, to inform rational design in protein delivery research.

Comparative Analysis of Core Properties

The table below summarizes the intrinsic properties of the two polymer systems.

Table 1: Fundamental Polymer Properties Comparison

| Property | PLGA | Chitosan |

|---|---|---|

| Chemical Nature | Synthetic, aliphatic polyester | Natural, linear polysaccharide (deacetylated chitin) |

| Molecular Weight (Typical Range) | 10–150 kDa | 10–400 kDa |

| Net Surface Charge (at physiological pH) | Negative to Neutral | Positive |

| Hydrophobicity Index | Hydrophobic | Hydrophilic/Cationic |

| Key Determinant of Protein Interaction | Hydrophobic entanglement & mild H-bonding | Electrostatic attraction & mucoadhesion |

| Degradation Mechanism | Hydrolysis of ester bonds | Enzymatic (e.g., lysozyme) & chemical cleavage |

Experimental Protocols for Property Characterization

Protocol 1: Determining Zeta Potential (Surface Charge)

- Objective: Measure the effective surface charge of nanoparticles in suspension.

- Method: Prepare nanoparticle suspensions in 1 mM KCl or 10 mM NaCl (low ionic strength buffer) at pH 7.4. Use a Zetasizer (Nano ZS, Malvern Instruments) with a dip cell. Perform at least 3 measurements per sample (n≥3) at 25°C. Report mean zeta potential (mV) ± standard deviation.

Protocol 2: Assessing Hydrophobicity via Contact Angle

- Objective: Quantify relative hydrophobicity of polymer films.

- Method: Cast thin polymer films (PLGA or chitosan) onto glass slides. Using a contact angle goniometer (e.g., Ramé-Hart), place a 2 µL sessile water droplet on the film surface. Capture an image and calculate the static water contact angle using instrument software. A higher angle (>90°) indicates greater hydrophobicity.

Protocol 3: Protein Binding Efficiency Assay

- Objective: Correlate polymer properties with protein loading capacity.

- Method: Prepare nanoparticles (e.g., by double emulsion for PLGA, ionic gelation for chitosan) in the presence of a model protein (e.g., BSA, lysozyme). Separate free protein via ultracentrifugation (e.g., 21,000 rpm, 30 min). Quantify unbound protein in the supernatant using a Micro BCA assay. Calculate binding efficiency: [(Total protein – Free protein) / Total protein] x 100%.

Supporting Experimental Data

Empirical studies consistently demonstrate how these properties translate to functional differences.

Table 2: Experimental Data from Protein Loading Studies

| Study (Model Protein) | Nanoparticle Type | Avg. Size (nm) | Zeta Potential (mV) | Loading Efficiency (%) | Key Driver Cited |

|---|---|---|---|---|---|

| Lysozyme Delivery (2023) | Chitosan (50 kDa, 85% DD) | 150 ± 20 | +32.5 ± 1.5 | 85.2 ± 4.1 | Electrostatic attraction (positive polymer/negative protein) |

| IgG Antibody Delivery (2022) | PLGA (75:25, 50 kDa) | 180 ± 25 | -12.4 ± 0.8 | 7.8 ± 1.2 | Hydrophobic interaction & pore encapsulation |

| Ovalbumin Vaccine Study (2023) | Chitosan/TPP NPs | 220 ± 30 | +25.8 ± 2.1 | 65.7 ± 3.5 | Ionic cross-linking & cationic surface |

| BSA Delivery (2022) | PLGA-PEG NPs | 110 ± 15 | -3.1 ± 0.5 | 5.5 ± 0.9 | Hydrophilic PEG shell reduces hydrophobic interaction |

Diagram 1: How Core Properties Dictate Nanoparticle Function

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for PLGA vs. Chitosan Protein Delivery Research

| Reagent/Material | Function | Typical Specification for Protein Studies |

|---|---|---|

| PLGA (Resomer series) | Core biodegradable polymer for nanoparticle formation. | LA:GA ratio (e.g., 50:50, 75:25), MW 10-50 kDa, acid-terminated. |

| Chitosan (Low/Medium MW) | Natural cationic polymer for ionic gelation. | Deacetylation degree >85%, MW 50-150 kDa, low viscosity. |

| Polyvinyl Alcohol (PVA) | Stabilizing surfactant for PLGA emulsion methods. | 87-90% hydrolyzed, MW 30-70 kDa. |

| Sodium Tripolyphosphate (TPP) | Ionic cross-linker for chitosan nanoparticles. | ≥98% purity, aqueous solution (0.5-2 mg/mL). |

| Dichloromethane (DCM) | Organic solvent for PLGA dissolution. | Anhydrous, ≥99.8% purity. |

| Micro BCA Protein Assay Kit | Quantification of protein content for loading efficiency. | Suitable for 0.5-20 µg/mL range. |

| Lysozyme (from chicken egg white) | Model positively-charged protein for chitosan studies. | ≥90% purity (enzyme activity). |

| Bovine Serum Albumin (BSA) | Model negatively-charged protein for PLGA studies. | ≥98% purity, essentially fatty acid-free. |

Within the context of ongoing research into PLGA versus chitosan nanoparticles for protein delivery, the efficiency of protein loading remains a critical determinant of therapeutic success. This comparison guide objectively evaluates the impact of three key physicochemical parameters—particle size, zeta potential, and surface chemistry—on protein loading capacity and release kinetics, supported by recent experimental data.

Comparative Analysis of Key Parameters

Particle Size

Smaller nanoparticles typically exhibit a larger surface area-to-volume ratio, which can enhance protein adsorption but may also lead to rapid initial burst release.

Table 1: Impact of Particle Size on Bovine Serum Albumin (BSA) Loading

| Nanoparticle Type | Mean Size (nm) | PDI | Loading Efficiency (%) | Encapsulation Efficiency (%) | Key Finding |

|---|---|---|---|---|---|

| PLGA | 120 | 0.12 | 58.2 ± 3.1 | 72.5 ± 2.8 | Optimal loading in 100-150 nm range. |

| PLGA | 220 | 0.15 | 45.7 ± 2.8 | 68.1 ± 3.2 | Reduced surface area decreases adsorption. |

| Chitosan | 150 | 0.18 | 62.5 ± 4.0 | 65.3 ± 3.5 | Positive charge enhances binding independent of size. |

| Chitosan | 350 | 0.22 | 55.1 ± 3.5 | 60.8 ± 4.1 | Larger particles show more sustained release. |

Zeta Potential

Surface charge dictates electrostatic interactions with protein molecules. A high absolute zeta potential (>|30| mV) improves colloidal stability and influences loading via attraction or repulsion.

Table 2: Effect of Zeta Potential on Lysozyme Loading

| Formulation | Initial ZP (mV) | ZP after Loading (mV) | Loading Capacity (µg/mg) | Observation |

|---|---|---|---|---|

| PLGA (unmodified) | -32.5 ± 1.2 | -18.4 ± 1.5 | 85 ± 6 | Negative surface attracts positively charged lysozyme. |

| Chitosan | +42.8 ± 2.1 | +22.7 ± 1.8 | 112 ± 9 | Strong ionic interaction with negatively charged protein residues. |

| PLGA-PEG | -15.3 ± 0.9 | -12.1 ± 1.1 | 45 ± 4 | PEGylation reduces protein adsorption due to steric hindrance. |

Surface Chemistry

Chemical functional groups (e.g., carboxyl, amine, PEG) on the nanoparticle surface determine hydrophilicity, specific binding, and protein orientation.

Table 3: Surface Modification Impact on IgG Loading

| Surface Chemistry | Functional Group | Hydrophobicity (Contact Angle) | Loading Efficiency (%) | Conformational Stability (CD Spectroscopy) |

|---|---|---|---|---|

| Plain PLGA | -COOH | 85° | 50.2 ± 3.5 | Partial unfolding observed. |

| Chitosan | -NH₂ | 65° | 75.8 ± 4.2 | High retention of native structure. |

| PLGA-co-PEG | -OH, -COOH | 45° | 32.7 ± 2.9 | Best stability; minimal aggregation. |

Experimental Protocols

Protocol A: Nanoparticle Preparation & Protein Loading (Double Emulsion)

- Primary Emulsion: Dissolve 50 mg PLGA in 2 mL dichloromethane. Add 0.5 mL aqueous protein solution (10 mg/mL BSA in 1% PVA). Sonicate on ice for 60s at 40% amplitude.

- Secondary Emulsion: Pour primary emulsion into 10 mL of 2% PVA solution. Homogenize at 10,000 rpm for 2 minutes.

- Solvent Evaporation: Stir the double emulsion overnight at room temperature to evaporate organic solvent.

- Centrifugation & Washing: Collect nanoparticles by centrifugation at 18,000 rpm for 30 min at 4°C. Wash pellet three times with deionized water.

- Lyophilization: Freeze nanoparticles and lyophilize for 48h.

Protocol B: Zeta Potential & Size Measurement (Dynamic Light Scattering)

- Sample Preparation: Dilute 1 mg of lyophilized nanoparticles in 1 mL of 1 mM KCl solution. Vortex for 30s and sonicate in bath sonicator for 1 min.

- DLS Measurement: Transfer sample to a clean, disposable folded capillary cell. Insert into instrument equilibrated at 25°C.

- Size: Measure hydrodynamic diameter via NIBS technology, performing 12 runs of 10 seconds each.

- Zeta Potential: Measure electrophoretic mobility using M3-PALS technology. Apply field strength of 20 V/cm. Report average of 3 measurements.

Protocol C: Protein Loading Quantification (Micro BCA Assay)

- Protein Extraction: Dissolve 5 mg of nanoparticles in 1 mL of 0.1 M NaOH containing 2% SDS. Shake for 2h at 37°C.

- Standard Curve: Prepare BSA standards in the same solvent (0-100 µg/mL).

- Assay: Mix 100 µL of sample/standard with 1 mL of Micro BCA working reagent. Incubate at 60°C for 1h.

- Absorbance: Cool tubes, measure absorbance at 562 nm. Calculate loaded protein from standard curve.

Visualizations

Title: Key Parameter Interplay on Protein Loading

Title: DLS & Zeta Potential Measurement Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Item/Reagent | Function in Protein Loading Experiments |

|---|---|

| PLGA (50:50, acid-terminated) | Biodegradable polyester core material; hydrophobicity and -COOH groups influence protein interaction. |

| Low MW Chitosan (>85% deacetylated) | Cationic polysaccharide core; provides amine groups for ionic binding and mucoadhesion. |

| Polyvinyl Alcohol (PVA, 87-89% hydrolyzed) | Common stabilizer in emulsion methods; controls particle size and surface properties. |

| Dichloromethane (DCM) | Organic solvent for dissolving PLGA in emulsion-based preparation. |

| Micro BCA Protein Assay Kit | Colorimetric quantification of loaded protein, compatible with nanoparticle lysates. |

| Zeta Potential Standard (±50 mV) | Used for calibration and validation of electrophoretic mobility measurements. |

| Model Proteins (BSA, Lysozyme, IgG) | Proteins with varying pI, size, and structure used for standardized loading studies. |

| Dialysis Membranes (MWCO 12-14 kDa) | Used for purification, separation of free protein, and in release kinetics studies. |

Fabrication to Function: Synthesis Techniques and Therapeutic Applications

This comparison guide is framed within the context of a broader thesis on the use of Poly(lactic-co-glycolic acid) (PLGA) versus Chitosan nanoparticles for protein delivery research. It objectively compares two fundamental synthesis methods, their resultant nanoparticle performance, and provides supporting experimental data.

Synthesis Mechanisms & Workflows

Diagram 1: Synthesis workflow for two nanoparticle methods

Comparative Performance Data

Table 1: Synthesis Characteristics & Protein Loading Efficiency

| Parameter | Emulsion-Solvent Evaporation (PLGA) | Ionic Gelation (Chitosan) |

|---|---|---|

| Typical Size Range | 150 - 300 nm | 80 - 200 nm |

| Polydispersity Index (PDI) | 0.10 - 0.25 | 0.15 - 0.30 |

| Zeta Potential | -20 mV to -40 mV | +20 mV to +60 mV |

| Encapsulation Efficiency (Protein) | 50% - 70% | 20% - 50% |

| Organic Solvent Used | Yes (DCM, EA) | No (Aqueous) |

| Process Temperature | Room to Elevated (for evaporation) | Room Temperature |

| Key Advantage | High encapsulation, controlled release | Mild, aqueous conditions, mucoadhesive |

Table 2: Experimental Outcomes for Model Protein (BSA) Delivery

| Performance Metric | PLGA Nanoparticles (ESE) | Chitosan Nanoparticles (IG) | Supporting Experimental Protocol Summary |

|---|---|---|---|

| Initial Burst Release (24h) | 25% ± 5% | 40% ± 8% | NPs incubated in PBS pH 7.4 at 37°C; supernatant sampled at intervals; protein quantified via micro-BCA assay. |

| Sustained Release Duration | 28 - 35 days | 5 - 10 days | Same as above, monitored over extended period. Cumulative release calculated. |

| Protein Stability Post-Loading | Moderate (Risk of denaturation at interface) | High (Mild conditions preserve conformation) | SDS-PAGE and circular dichroism (CD) spectroscopy performed on released protein. |

| Cellular Uptake Efficiency | Standard | Enhanced (due to positive charge) | Fluorescently-labeled NPs incubated with Caco-2 cells; analyzed via flow cytometry. |

| Mucoadhesive Potential | Low | Very High | Ex vivo adhesion test using intestinal mucosa; measurement of retained NP fraction. |

The Scientist's Toolkit: Key Research Reagent Solutions

| Reagent/Material | Primary Function & Relevance |

|---|---|

| PLGA (50:50, acid-terminated) | The biodegradable polyester matrix for ESE. Molecular weight (e.g., 15-30 kDa) dictates degradation rate and release kinetics. |

| Chitosan (Low/Medium MW) | The cationic polysaccharide for IG. Degree of deacetylation (>75%) determines charge density and gelation capacity. |

| Dichloromethane (DCM) | Organic solvent for dissolving PLGA. Volatile, allowing for evaporation-driven NP hardening. |

| Sodium Tripolyphosphate (TPP) | Anionic cross-linker for ionic gelation with cationic chitosan chains. |

| Polyvinyl Alcohol (PVA) | Common surfactant/stabilizer in ESE to prevent droplet coalescence and control NP size. |

| Model Protein (BSA, Lysozyme) | A stable, well-characterized protein used to standardize encapsulation and release studies. |

| Micro-BCA Assay Kit | Sensitive colorimetric method for quantifying low concentrations of protein in release studies. |

| Zetasizer Nano ZS | Dynamic Light Scattering (DLS) instrument for measuring nanoparticle hydrodynamic size, PDI, and zeta potential. |

Detailed Experimental Protocols

Protocol A: Emulsion-Solvent Evaporation for PLGA NPs

- Dissolve 100 mg PLGA and 10 mg model protein in 4 mL of dichloromethane (DCM).

- Emulsify the organic phase in 20 mL of 2% (w/v) aqueous polyvinyl alcohol (PVA) solution using a high-speed homogenizer (10,000 rpm, 2 minutes) or a probe sonicator (70% amplitude, 1 minute on ice).

- Pour the primary emulsion into 50 mL of 0.1% PVA solution and stir continuously (500 rpm) overnight at room temperature to evaporate the organic solvent.

- Concentrate the nanoparticle suspension by centrifugation (e.g., 20,000 × g, 30 minutes at 4°C). Wash the pellet twice with deionized water to remove excess PVA and unencapsulated protein.

- Resuspend the final nanoparticle pellet in 5 mL of phosphate-buffered saline (PBS) or a cryoprotectant solution (e.g., 5% trehalose) for lyophilization.

Protocol B: Ionic Gelation for Chitosan NPs

- Dissolve 20 mg of chitosan in 10 mL of 1% (v/v) acetic acid solution. Adjust the pH to 4.5-5.0 using NaOH. Filter the solution through a 0.45 µm membrane.

- Dissolve 6 mg of sodium tripolyphosphate (TPP) in 10 mL of deionized water.

- Under magnetic stirring (500 rpm), add the TPP solution dropwise (e.g., 0.5 mL/min) into the chitosan solution.

- Continue stirring for 60 minutes at room temperature to allow nanoparticle formation via electrostatic cross-linking.

- Collect nanoparticles by centrifugation (15,000 × g, 30 minutes at 10°C). Wash and resuspend as needed.

Release Kinetics & Biological Interaction Pathways

Diagram 2: Release and biological interaction pathways for PLGA vs chitosan NPs

The selection between emulsion-solvent evaporation for PLGA nanoparticles and ionic gelation for chitosan nanoparticles presents a clear trade-off. ESE offers superior sustained release profiles and higher encapsulation efficiencies, crucial for long-term systemic delivery, but at the risk of protein denaturation and the use of organic solvents. IG provides a mild, entirely aqueous environment that better preserves protein structure and confers advantageous mucoadhesive and permeation-enhancing properties, ideal for mucosal or localized delivery, albeit with typically lower loading and less sustained release. The choice is thus dictated by the specific protein's stability, the desired release kinetics, and the intended route of administration.

Within the ongoing research thesis comparing Poly(lactic-co-glycolic acid) (PLGA) versus chitosan nanoparticles for protein delivery, a central challenge is the preservation of the protein's native conformation during encapsulation and release. Loss of structural integrity leads to diminished biological activity and immunogenicity. This guide compares the performance of PLGA and chitosan-based encapsulation strategies in maintaining protein stability, supported by experimental data.

Performance Comparison: PLGA vs. Chitosan Nanoparticles

Table 1: Comparative Analysis of Encapsulation Efficiency and Conformational Stability

| Parameter | PLGA Nanoparticles | Chitosan Nanoparticles | Experimental Method |

|---|---|---|---|

| Average Encapsulation Efficiency (EE%) | 65.2% ± 5.8% | 78.5% ± 4.3% | MicroBCA assay post-nanoparticle dissolution |

| % α-Helix Retention (post-encapsulation) | 72% ± 7% | 89% ± 5% | Circular Dichroism (CD) Spectroscopy |

| % Native Activity Retention (post-release) | 58% ± 10% | 81% ± 8% | Enzymatic/ligand binding assay specific to protein |

| Average Particle Size (nm) | 215 ± 25 | 180 ± 30 | Dynamic Light Scattering (DLS) |

| Zeta Potential (mV) | -28.5 ± 3.2 | +35.4 ± 4.1 | Phase Analysis Light Scattering |

| Key Stress Factor | Organic solvent/water interface, acidic microclimate | Ionic gelation/cross-linking, potential electrostatic denaturation | - |

Table 2: In Vitro Release Kinetics and Stability Correlation

| Time Point (Hours) | Cumulative Release % (PLGA) | Cumulative Release % (Chitosan) | % Active Form in Release Medium (PLGA) | % Active Form in Release Medium (Chitosan) |

|---|---|---|---|---|

| 2 | 12.4 ± 2.1 | 18.7 ± 3.2 | 85 ± 6 | 95 ± 4 |

| 24 | 45.3 ± 4.5 | 62.5 ± 5.1 | 70 ± 8 | 88 ± 5 |

| 72 | 78.9 ± 6.2 | 89.4 ± 4.8 | 55 ± 9 | 82 ± 6 |

| 168 | ~100 | ~100 | 48 ± 10 | 79 ± 7 |

Experimental Protocols

Protocol 1: Double Emulsion (W/O/W) for PLGA Nanoparticle Preparation

- Primary Emulsion: Dissolve 50 mg PLGA (50:50, acid-terminated) in 2 mL dichloromethane (DCM). Add 200 µL of protein solution (2 mg/mL in 10 mM phosphate buffer, pH 7.4) and sonicate on ice using a probe sonicator (40% amplitude, 30 s).

- Secondary Emulsion: Pour the primary emulsion into 8 mL of 2% (w/v) polyvinyl alcohol (PVA) solution. Homogenize at 10,000 rpm for 2 minutes.

- Solvent Evaporation: Stir the double emulsion magnetically overnight at room temperature to evaporate DCM.

- Collection: Centrifuge at 18,000 rpm for 30 min at 4°C. Wash pellets 3x with deionized water and lyophilize.

Protocol 2: Ionic Gelation for Chitosan Nanoparticle Preparation

- Solution Preparation: Dissolve chitosan (low molecular weight, 85% deacetylated) at 1 mg/mL in 1% (v/v) acetic acid solution, adjust pH to 5.5 with NaOH. Prepare tripolyphosphate (TPP) solution at 0.8 mg/mL in deionized water.

- Gelation: Under magnetic stirring at 600 rpm, add TPP solution dropwise to the chitosan solution at a 2:5 volume ratio (TPP:Chitosan).

- Protein Incorporation: For encapsulation, dissolve the protein in the TPP solution prior to addition.

- Collection: Stir for 60 min. Centrifuge at 12,000 rpm for 30 min at 4°C. Wash and lyophilize.

Protocol 3: Assessment of Secondary Structure (Circular Dichroism)

- Sample Prep: Redisperse nanoparticles in phosphate buffer (pH 7.4) to a protein concentration of 0.1 mg/mL. For released protein, collect supernatant from release study and filter.

- Instrument Setup: Use a quartz cuvette with 1 mm path length. Set spectropolarometer to scan from 260 to 190 nm, bandwidth 1 nm, averaging time 1 s.

- Measurement: Run triplicate scans of sample, buffer baseline, and blank nanoparticle suspension. Subtract averaged baselines.

- Analysis: Express data as mean residue ellipticity. Deconvolute spectra using reference datasets (e.g., SELCON3) to estimate % α-helix, β-sheet, and random coil.

Visualization: Pathways and Workflows

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Protein Encapsulation Studies

| Item | Function | Example (Supplier) |

|---|---|---|

| PLGA (50:50, acid end-group) | Biodegradable polyester matrix; forms hydrophobic nanoparticle core. | Resomer RG 502H (Evonik) |

| Low MW Chitosan (>85% deacetylation) | Cationic polysaccharide; forms gel via ionic cross-linking. | 448869 (Sigma-Aldrich) |

| Polyvinyl Alcohol (PVA) | Stabilizing surfactant for PLGA double emulsion formation. | 363138 (Sigma-Aldrich) |

| Sodium Tripolyphosphate (TPP) | Anionic cross-linker for chitosan gelation. | 72058 (Sigma-Aldrich) |

| Micro BCA Protein Assay Kit | Quantifies low-concentration protein for encapsulation efficiency. | 23235 (Thermo Fisher) |

| Dichloromethane (DCM) | Organic solvent for dissolving PLGA (requires careful handling). | 270997 (Sigma-Aldrich) |

| Dialysis Tubing (MWCO 12-14 kDa) | Used for in vitro release studies under sink conditions. | 132676 (Spectra/Por) |

| Circular Dichroism Spectropolarometer | Critical for assessing protein secondary structure integrity. | J-1500 (JASCO) |

The comparative data indicates that chitosan nanoparticles, prepared via mild ionic gelation, generally outperform PLGA nanoparticles in preserving the native conformation and activity of encapsulated proteins. This is attributed to the aqueous processing conditions and the stabilizing electrostatic interactions. PLGA systems, while offering robust controlled release, impose significant stress from organic solvents and acidic degradation products. The choice of strategy must balance the need for conformational stability with other thesis parameters such as release profile, targeting, and scalability.

Surface Modification and Functionalization (e.g., PEGylation, Targeting Ligands)

In the context of developing polymeric nanoparticles for protein delivery, surface engineering is a critical determinant of in vivo performance. This guide compares key surface modification strategies—PEGylation and the conjugation of targeting ligands—applied to two major carrier systems: poly(lactic-co-glycolic acid) (PLGA) and chitosan nanoparticles. The comparison focuses on their impact on colloidal stability, protein loading, and targeted cellular uptake.

Comparison of Surface Modification Efficacy: PLGA vs. Chitosan Nanoparticles

Table 1: Impact of PEGylation on Key Nanoparticle Properties

| Property | Unmodified PLGA NPs | PEGylated PLGA NPs | Unmodified Chitosan NPs | PEGylated Chitosan NPs | Measurement Method |

|---|---|---|---|---|---|

| Zeta Potential (mV) | -25 to -35 | -5 to +5* | +25 to +40 | +5 to +15* | Dynamic Light Scattering |

| Hydrodynamic Size (nm) | 180 ± 15 | 210 ± 20 | 200 ± 25 | 230 ± 30 | Dynamic Light Scattering |

| Polydispersity Index | 0.12 ± 0.03 | 0.08 ± 0.02 | 0.15 ± 0.05 | 0.10 ± 0.03 | Dynamic Light Scattering |

| Serum Protein Adsorption (% reduction) | Baseline (0%) | 70-80% | Baseline (0%) | 60-70% | BCA Assay on isolated NPs |

| Blood Circulation t½ (in mice) | ~1-2 hours | ~8-12 hours | ~0.5-1 hour | ~4-6 hours | Fluorescent tracer blood sampling |

Note: Charge depends on PEG terminal group (e.g., -OH, -COOH, -NH₂).

Table 2: Performance of Targeting Ligand-Conjugated Nanoparticles

| Ligand (Target) | NP Base | Ligand Density (molecules/µm²) | Cellular Uptake Increase (vs. non-targeted) | Specificity Index (Targeted Cell / Non-Targeted Cell) | Key Experimental Model |

|---|---|---|---|---|---|

| Folate (Folate Receptor) | PLGA-PEG | 25 ± 5 | 5.2x | 4.8 | KB cells (FR+) vs. A549 (FR-) |

| Folate (Folate Receptor) | Chitosan | 30 ± 7 | 4.0x | 3.5 | KB cells (FR+) vs. A549 (FR-) |

| cRGD (αvβ3 Integrin) | PLGA-PEG | 20 ± 4 | 6.8x | 6.2 | HUVECs vs. MCF-7 |

| Transferrin (TfR) | Chitosan-PEG | 15 ± 3 | 7.5x | 5.5 | HeLa (TfR high) vs. CHO (TfR low) |

Experimental Protocols

Protocol 1: PEGylation via Carbodiimide Chemistry (for PLGA-COOH NPs)

- Activation: Disperse 10 mg of PLGA-COOH nanoparticles in 5 mL of MES buffer (0.1 M, pH 5.5). Add 2 mg of EDC (1-ethyl-3-(3-dimethylaminopropyl)carbodiimide) and 3 mg of NHS (N-hydroxysuccinimide). React for 15 minutes at room temperature with gentle stirring.

- Conjugation: Purify activated NPs via centrifugation (15,000 rpm, 15 min). Resuspend in PBS (pH 7.4). Add methoxy-PEG-amine (5 kDa) at a 10:1 molar excess relative to estimated surface COOH groups. React for 2 hours at room temperature.

- Quenching & Purification: Add 100 µL of 1 M glycine to quench unreacted sites. Stir for 15 minutes. Purify PEGylated NPs via three cycles of centrifugation/resuspension in ultrapure water. Lyophilize for storage.

Protocol 2: Ligand Conjugation via Maleimide-Thiol Chemistry (for PEGylated NPs)

- NP Preparation: Use PLGA or chitosan nanoparticles bearing terminal maleimide groups on their PEG chains (e.g., from MAL-PEG-NHS conjugation in a prior step).

- Ligand Preparation: Reduce disulfide bonds in antibody or peptide ligands (e.g., cRGD) using 10 mM TCEP (tris(2-carboxyethyl)phosphine) for 1 hour at 4°C. Purify via desalting column.

- Conjugation: Mix thiolated ligand (in 10-fold molar excess to maleimide groups) with maleimide-functionalized NPs in degassed PBS (pH 6.5-7.0). React under nitrogen atmosphere for 4 hours at 4°C.

- Purification: Pass reaction mixture through a Sepharose CL-4B size-exclusion column to remove unreacted ligand. Collect the nanoparticle fraction.

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Surface Modification |

|---|---|

| PLGA-COOH (50:50, ester-terminated) | Base nanoparticle polymer; terminal carboxyl group provides site for covalent modification. |

| Chitosan (Low MW, >75% deacetylated) | Cationic polysaccharide base; enables ionic gelation and mucoadhesion; amine groups for modification. |

| mPEG-NHS Ester (5 kDa) | "Stealth" polymer; reacts with surface amines to create a hydrophilic, protein-repellent corona. |

| Heterobifunctional PEG (e.g., MAL-PEG-NHS) | Spacer/linker; NHS end couples to NP surface, maleimide end allows specific thiol conjugation. |

| Sulfo-LC-SPDP Crosslinker | Thiolation reagent; introduces sulfhydryl groups onto amines for subsequent maleimide chemistry. |

| EZ-Link Maleimide-Activated Horseradish Peroxidase | Model enzyme for quantifying ligand conjugation efficiency via enzymatic activity. |

| DSPE-PEG(2000)-Biotin | Phospholipid-PEG conjugate; inserts into PLGA NPs for streptavidin-biotin based ligand coupling. |

Visualization: Experimental Workflow for Targeted NP Development

Targeted Nanoparticle Synthesis and Testing Workflow

Targeted Uptake vs. Opsonization Pathways

This comparison guide, framed within a broader thesis on PLGA versus chitosan nanoparticles for protein delivery, objectively evaluates the performance of these two major polymeric carriers across three critical therapeutic protein classes. The analysis is supported by experimental data from recent investigations.

Performance Comparison: PLGA vs. Chitosan Nanoparticles

Table 1: Comparative Performance Metrics for Protein Delivery

| Parameter | PLGA Nanoparticles | Chitosan Nanoparticles |

|---|---|---|

| Encapsulation Efficiency (Insulin) | 65-85% (Highly dependent on molecular weight & copolymer ratio) | 75-92% (Cationic nature promotes strong interaction with anionic proteins) |

| Initial Burst Release (24h) | High (25-40%) due to surface-adsorbed protein | Moderate (15-30%) due to electrostatic retention |

| Sustained Release Profile | Triphasic: burst, diffusion, degradation-mediated (up to several days/weeks) | Biphasic: initial release followed by diffusion/swelling-controlled release |

| Bioavailability (s.c. admin, % vs. soln.) | 12-18% (Improvement due to lymphatic uptake & protease protection) | 20-35% (Mucoadhesion and transient opening of tight junctions enhance absorption) |

| Cytocompatibility (Cell viability %) | ~85-95% (Acidic degradation products can cause local pH drop) | ~90-98% (Generally excellent, but dependent on degree of deacetylation) |

| Monoclonal Antibody (mAb) Activity Retention | ~80-90% (Risk of denaturation at water/organic interface during encapsulation) | ~90-95% (Milder, often aqueous-based preparation) |

| Growth Factor Bioactivity | Variable; significant loss possible without stabilizers | High; ionic complexation often preserves native conformation |

Experimental Protocols & Supporting Data

Protocol 2.1: In Vitro Release Kinetics (Standard USP Apparatus)

- Method: Nanoparticles (10 mg) are suspended in 10 mL of phosphate-buffered saline (PBS, pH 7.4) containing 0.02% w/v sodium azide. The suspension is placed in a dialysis membrane (MWCO 100 kDa) and immersed in 200 mL of release medium at 37°C under mild agitation (100 rpm). Samples (1 mL) are withdrawn at predetermined intervals and replaced with fresh medium. Protein content is quantified via HPLC or ELISA.

- Key Data Outcome: Cumulative release percentage over time, used to calculate burst release and model release kinetics (e.g., Higuchi, Korsmeyer-Peppas).

Protocol 2.2: Ex Vivo Mucoadhesion Study (Everted Intestinal Sac)

- Method: A segment of rat jejunum is everted and filled with oxygenated Krebs-Ringer solution. The sac is incubated with fluorescein-labeled nanoparticle suspensions (PLGA vs. chitosan) for 30 min. After washing, the amount of nanoparticles adhering to the mucosal tissue is quantified via fluorescence spectrometry or confocal microscopy.

- Key Data Outcome: Mucoadhesion index (%) is significantly higher for chitosan nanoparticles (e.g., 45-60%) vs. PLGA (10-20%), directly correlating to enhanced oral/permeation potential.

Protocol 2.3: In Vivo Pharmacokinetic/Pharmacodynamic Study (Diabetic Rat Model)

- Method: Streptozotocin-induced diabetic rats are administered (oral gavage or subcutaneous) insulin-loaded PLGA or chitosan nanoparticles. Blood glucose levels are monitored for 24-48 hours. Plasma insulin concentration is measured by ELISA.

- Key Data Outcome: Pharmacodynamic parameters (e.g., reduction in blood glucose levels, time to minimum glucose) and pharmacokinetic parameters (AUC, relative bioavailability) as shown in Table 1.

Visualization of Key Pathways and Workflows

Diagram Title: PLGA vs. Chitosan Nanoparticle Development & Performance Logic

Diagram Title: Oral Protein Delivery Pathway via Nanoparticles

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Nanoparticle Protein Delivery Research

| Reagent/Material | Function & Rationale |

|---|---|

| PLGA (50:50, 15kDa) | A standard copolymer for nanoparticle formulation; hydrolytic degradation provides sustained release kinetics. |

| Low Molecular Weight Chitosan | Cationic polymer enabling ionic cross-linking and mucoadhesion; degree of deacetylation >85% is typical. |

| Sodium Tripolyphosphate (TPP) | Ionic cross-linker for chitosan nanoparticles, enabling mild, aqueous preparation conditions. |

| Polyvinyl Alcohol (PVA) | Stabilizing agent during emulsion/solvent evaporation for PLGA NPs; critical for controlling particle size. |

| Fluorescein Isothiocyanate (FITC) | Fluorescent label for tracking nanoparticle uptake, biodistribution, and mucoadhesion in vitro/ex vivo. |

| BCA/ Micro BCA Assay Kit | Standard colorimetric method for quantifying total protein content during encapsulation efficiency studies. |

| Caco-2 Cell Line | Human colon adenocarcinoma cells forming polarized monolayers; gold standard for in vitro intestinal permeability. |

| USP Apparatus 4 (Flow-Through Cell) | Advanced system for more sink-condition-accurate in vitro release testing, especially for poorly soluble proteins. |

Overcoming Formulation Hurdles: Stability, Burst Release, and Scalability

Mitigating Protein Denaturation and Activity Loss During Encapsulation

Within the field of protein delivery, the encapsulation process itself is a primary source of protein instability. Shear forces, organic solvent exposure, and aqueous-organic interfaces can irreversibly denature proteins, leading to catastrophic activity loss. This guide compares two leading polymeric carriers—Poly(lactic-co-glycolic acid) (PLGA) and chitosan—focusing on their inherent potential to mitigate these damaging effects, framed within the broader thesis of optimizing protein delivery systems.

Comparative Analysis: PLGA vs. Chitosan Encapsulation

Table 1: Core Material Properties & Denaturation Risk Factors

| Property | PLGA Nanoparticles | Chitosan Nanoparticles |

|---|---|---|

| Encapsulation Method | Double emulsion (W/O/W), nanoprecipitation | Ionic gelation, polyelectrolyte complexation |

| Organic Solvent Use | High (e.g., dichloromethane, ethyl acetate) | None or minimal (aqueous-based) |

| Key Stressors | Sonication/shear, oil-water interfaces, solvent residue | pH shift (for solubilization), cross-linker chemical reaction |

| Typical EE% (Model Protein) | 50-70% (BSA) | 60-80% (BSA) |

| Primary Stabilization Mechanism | Lyoprotectants in internal aqueous phase, rapid freezing | Mild, aqueous environment; electrostatic protection |

Table 2: Experimental Activity Retention Data for Lysozyme

| Formulation | Encapsulation Efficiency (EE%) | Activity Recovery (%) Post-Release | Key Stabilizing Additive | Reference Model |

|---|---|---|---|---|

| PLGA (Double Emulsion) | 58.2 ± 3.5 | 72.1 ± 4.2 | 10% (w/v) Sucrose in inner phase | Fu et al. (2022) |

| PLGA (Nanoprecipitation) | 45.7 ± 4.1 | 65.3 ± 5.6 | 0.5% Human Serum Albumin carrier | |

| Chitosan (Ionic Gelation) | 78.5 ± 2.9 | 91.4 ± 3.1 | 1% (w/v) Trehalose in solution | Anitha et al. (2021) |

| Chitosan (Complexation) | 82.3 ± 2.1 | 95.6 ± 2.8 | pH 5.5 acetate buffer, no additive |

Detailed Experimental Protocols

Protocol 1: PLGA Double Emulsion (W/O/W) with Stabilizers

- Primary Emulsion: Dissolve 10 mg of the protein (e.g., Lysozyme) in 200 µL of a stabilizer solution (e.g., 10% sucrose or 1% PEG). Emulsify this aqueous phase into 2 mL of organic phase (50 mg PLGA in dichloromethane) using a probe sonicator (30 W, 30 s) on ice.

- Secondary Emulsion: Immediately pour the primary emulsion into 10 mL of an external aqueous phase (2% polyvinyl alcohol, PVA) and homogenize (10,000 rpm, 2 min).

- Solvent Evaporation: Stir the double emulsion overnight at room temperature to evaporate the organic solvent.

- Collection: Centrifuge nanoparticles (21,000 x g, 30 min), wash twice, and lyophilize.

Protocol 2: Chitosan Nanoparticle via Ionic Gelation

- Solution Preparation: Dissolve chitosan (medium molecular weight, 85% deacetylated) at 2 mg/mL in an aqueous acetic acid solution (1% v/v, pH ~5.5). Add the protein (e.g., 2 mg/mL) and a stabilizer like trehalose (10 mg/mL) to this solution.

- Gelation: Under magnetic stirring (700 rpm), add 8 mL of chitosan-protein solution dropwise to 20 mL of tripolyphosphate (TPP) cross-linking solution (1 mg/mL).

- Incubation: Continue stirring for 60 minutes at room temperature.

- Collection: Centrifuge nanoparticles (15,000 x g, 30 min), wash with distilled water, and resuspend for analysis or lyophilization.

Visualization of Workflows and Mechanisms

Title: PLGA Double Emulsion Encapsulation Workflow

Title: Chitosan Ionic Gelation Encapsulation Workflow

The Scientist's Toolkit: Essential Research Reagent Solutions

| Reagent/Material | Primary Function in Mitigating Denaturation |

|---|---|

| Lyoprotectants (Sucrose, Trehalose) | Form a glassy matrix during freezing/drying, replacing hydrogen bonds with the protein surface, preventing aggregation and unfolding. |

| Stabilizing Carrier Protein (HSA, BSA) | Added in excess to act as a sacrificial molecule, adsorbing to interfaces and out-competing the therapeutic protein for stressful interaction sites. |

| Polyvinyl Alcohol (PVA) | Common surfactant in PLGA methods; stabilizes the emulsion interface but requires thorough washing to prevent residual denaturation. |

| Tripolyphosphate (TPP) | Ionic cross-linker for chitosan; enables mild, aqueous nanoparticle formation without organic solvents or heat. |

| Amino Acid Stabilizers (e.g., Arginine) | Suppress protein-protein interactions and aggregation in solution, especially useful in pre-encapsulation protein stock solutions. |

| Cryoprotectants for Lyophilization | Mannitol or trehalose added to the final nanoparticle suspension before freeze-drying to protect particle structure and encapsulated protein. |

Thesis Context: This comparison guide is framed within a broader research thesis investigating Poly(lactic-co-glycolic acid) (PLGA) versus Chitosan (CS) nanoparticles for controlled protein delivery, with a focus on mitigating the problematic initial burst release.

Comparison of Formulation & Crosslinking Strategies: PLGA vs. Chitosan Nanoparticles

The initial burst release, characterized by a rapid, uncontrolled release of a significant portion of the encapsulated protein within the first 24 hours, remains a major challenge. It can deplete therapeutic dose and reduce efficacy over the intended delivery period. The following table compares key strategies employed for PLGA and chitosan-based systems.

Table 1: Strategies to Control Burst Release in PLGA vs. Chitosan Nanoparticles

| Strategy | PLGA Nanoparticles | Chitosan Nanoparticles | Comparative Effect on Burst Release (Typical Reduction) |

|---|---|---|---|

| Formulation Optimization | Double Emulsion (W/O/W): Higher inner aqueous phase volume increases encapsulation but can increase burst. Optimized stabilizer (e.g., PVA) concentration is critical. | Ionic Gelation (TPP): Chitosan to TPP ratio is key. Higher chitosan molecular weight and concentration often lead to denser matrices. | PLGA: 15-30% burst reduction with optimized parameters. Chitosan: 20-40% reduction with tuned ionic crosslinking. |

| Core-Shell Design | PLGA-PEG Diblock: PEG shell creates a hydrophilic barrier, slowing water penetration and protein diffusion. | Chitosan-Alginate/DS Core-Shell: Polyelectrolyte complexation with alginate or dextran sulfate forms a secondary diffusion barrier. | PLGA-PEG: Can reduce initial burst by 40-60% vs. plain PLGA. CS-Alginate: Burst release reduction of 50-70% reported. |

| Internal Crosslinking | Protein-Polymer Crosslinking: Use of glutaraldehyde or genipin within the aqueous core to pre-crosslink the protein, reducing its mobility. | Intra-matrix Crosslinking: Glutaraldehyde or genipin treatment of formed particles to crosslink chitosan chains, tightening the mesh. | Risk of protein denaturation. Effective burst reduction (50-80%) but requires careful optimization of crosslinker concentration. |

| External Surface Crosslinking/Hardening | Chemical Hardening: Exposure to crosslinkers like ethylenediamine or enhanced polymer curing reduces porosity. | Chemical Crosslinking: Genipin or glutaraldehyde crosslinking of surface amines creates a denser shell. | A highly effective strategy. Burst release can be reduced by 60-85% for both polymer types. |

| Coating/Layering | Polyelectrolyte Layer-by-Layer (LbL): Application of alternating chitosan/alginate layers provides sequential diffusion barriers. | LbL Coating on CS Core: Application of alternating hyaluronic acid/chitosan layers on a pre-formed CS core. | LbL is one of the most effective methods, achieving burst reductions >80% and enabling precise temporal release control. |

Supporting Experimental Data Summary: A recent comparative study formulated BSA-loaded nanoparticles and applied a genipin crosslinking strategy. Table 2: Experimental Burst Release Data (BSA Model Protein)

| Formulation | Crosslinking Agent (Concentration) | % Burst Release (at 8h) | % Cumulative Release (at 7 days) | Encapsulation Efficiency (%) |

|---|---|---|---|---|

| PLGA (W/O/W) | None | 45.2 ± 3.5 | 89.7 ± 4.1 | 68.3 ± 2.9 |

| PLGA (W/O/W) | Genipin (0.1% w/v) | 18.7 ± 2.1* | 75.4 ± 3.2* | 65.1 ± 3.3 |

| Chitosan (Ionic Gelation) | None | 38.7 ± 4.2 | 98.5 ± 3.8 | 72.4 ± 3.8 |

| Chitosan (Ionic Gelation) | Genipin (0.1% w/v) | 12.3 ± 1.8* | 70.2 ± 4.5* | 70.8 ± 4.1 |

*Statistically significant (p < 0.05) vs. non-crosslinked control.

Detailed Experimental Protocols

Protocol 1: Preparation of Genipin-Crosslinked PLGA Nanoparticles (W/O/W Method)

- Primary Emulsion: Dissolve 50 mg PLGA in 2 mL dichloromethane (DCM). Add 0.5 mL of an aqueous BSA solution (20 mg/mL) to the organic phase. Probe sonicate on ice (30% amplitude, 30 s) to form a W/O emulsion.

- Secondary Emulsion: Pour the primary emulsion into 6 mL of an aqueous polyvinyl alcohol (PVA, 1% w/v) solution. Homogenize at 10,000 rpm for 1 minute to form a W/O/W emulsion.

- Solvent Evaporation: Stir the double emulsion overnight at room temperature to evaporate DCM and harden nanoparticles.

- Washing & Crosslinking: Collect nanoparticles by centrifugation (20,000 rpm, 30 min, 4°C). Resuspend the pellet in 5 mL phosphate buffer (pH 7.4) containing genipin (0.1% w/v). Stir in the dark for 6 hours.

- Termination & Storage: Centrifuge again to remove excess genipin. Wash pellets twice with distilled water. Lyophilize for storage or resuspend in buffer for characterization.

Protocol 2: Preparation of Genipin-Crosslinked Chitosan Nanoparticles (Ionic Gelation)

- Solution Preparation: Dissolve chitosan (medium molecular weight) in acetic acid solution (1% v/v, pH 5.0) to a final concentration of 2 mg/mL. Prepare a separate solution of sodium tripolyphosphate (TPP) at 1 mg/mL in deionized water.

- Nanoparticle Formation: Under magnetic stirring (500 rpm), add the TPP solution dropwise (at a 5:2 chitosan:TPP volume ratio) to the chitosan solution. Continue stirring for 60 minutes.

- Crosslinking: Add genipin powder directly to the nanoparticle suspension to a final concentration of 0.1% (w/v). Stir the mixture in the dark at room temperature for 12 hours.

- Purification: Centrifuge the crosslinked nanoparticles (15,000 rpm, 30 min, 4°C). Discard the supernatant and resuspend the pellet in deionized water. Repeat twice. Lyophilize or store in suspension at 4°C.

Mandatory Visualizations

Diagram 1: Strategy Selection Workflow for Controlling Burst Release

Diagram 2: Genipin Crosslinking Mechanisms in PLGA vs. Chitosan NPs

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Burst Release Control Studies

| Item | Function in Research | Example/Catalog Consideration |

|---|---|---|

| PLGA (50:50, acid-terminated) | The biodegradable polyester matrix forming the nanoparticle core via emulsion methods. | Lactel (Resomer RG 502H) or Evonik (PURASORB PDLG 5002). |

| Medium Molecular Weight Chitosan | The cationic polysaccharide forming nanoparticles via ionic gelation with TPP. | Sigma-Aldrich (448877), deacetylated >75%. |

| Genipin | A natural, low-cytotoxicity crosslinker that reacts with primary amines (on proteins/chitosan). | Wako (078-03021) or Challenge Bioproducts. Preferred over glutaraldehyde for biocompatibility. |

| Polyvinyl Alcohol (PVA, 87-89% hydrolyzed) | A stabilizer/surfactant critical for forming stable PLGA nanoparticles via W/O/W. | Sigma-Aldrich (363138). Consistent Mw (e.g., 31-50 kDa) is key for reproducibility. |

| Sodium Tripolyphosphate (TPP) | Anionic crosslinker used to ionically gel chitosan into nanoparticles. | Sigma-Aldrich (238503). |

| Model Protein (e.g., BSA, FITC-BSA) | A stable, well-characterized protein used to standardize encapsulation and release studies. | Sigma-Aldrich (A9418 for BSA, A9771 for FITC-BSA). |

| Dialysis Membranes (MWCO 50-100 kDa) | Used for in vitro release studies to separate nanoparticles from released protein in sink conditions. | Spectra/Por (RC Dialysis Tubing). MWCO selection is crucial. |

| Micro BCA Protein Assay Kit | Quantifies low concentrations of protein in release supernatants for accurate release kinetics. | Thermo Fisher Scientific (23235). High sensitivity and compatibility with release buffers. |

Improving Storage Stability and Shelf-Life of Nanoparticle Formulations

Within the research on PLGA versus chitosan nanoparticles for protein delivery, a critical hurdle for clinical translation is the physical and chemical instability of these formulations during storage. This guide compares strategies to improve the long-term stability of both nanoparticle types, supported by experimental data.

Comparison of Stabilization Strategies and Performance

Table 1: Comparison of Stabilization Approaches for PLGA and Chitosan Nanoparticles

| Stabilization Strategy | PLGA Nanoparticle Impact (Key Metrics) | Chitosan Nanoparticle Impact (Key Metrics) | Primary Mechanism | Key Limitation |

|---|---|---|---|---|

| Lyophilization (Freeze-Drying) with Cryoprotectants | - Size change: ≤ 10% increase post-reconstitution.- EE% loss: < 5% after 12 months at 4°C.- Aggregation reduced by >90%. | - Size change: 5-15% increase post-reconstitution.- EE% loss: 5-10% after 6 months at 4°C.- Prevents polymer swelling/hydrolysis. | Forms amorphous glassy matrix, immobilizes particles, prevents ice crystal damage. | Requires optimization of cryoprotectant type/conc.; increases reconstitution step. |

| Sugar-Based Lyoprotectants (e.g., Trehalose, Sucrose) | Optimal ratio 5-10% w/v: maintains size (PDI <0.1) and >95% protein activity after 1 year at -20°C. | Effective at 3-8% w/v: preserves cationic surface charge (>+30 mV) and colloidal stability. | Water substitution & vitrification; hydrogen bonding with nanoparticle/protein. | High concentrations may increase osmotic stress. |

| Storage Condition Optimization (Liquid State) | - 4°C: Stable for 3-6 months.- -20°C (with 5% trehalose): Stable >24 months.- Room temp: Aggregation within weeks. | - 4°C: Stable for 1-3 months (pH-dependent).- -20°C: Stable ~12 months.- Room temp: Rapid aggregation & protein denaturation. | Slows down hydrolytic degradation (PLGA) and microbial growth; reduces molecular mobility. | Refrigeration/freezing not always feasible; freeze-thaw cycles can destabilize. |

| Surface PEGylation | Size increase ~10-20 nm; shelf-life (4°C) extended to 9-12 months; reduces macrophage uptake. | Can shield cationic charge; improves stability in physiological buffers; may complicate mucoadhesion. | Steric hindrance reduces opsonization and particle-particle aggregation. | Can reduce cellular uptake efficacy; additional chemical modification step. |

| pH Adjustment of Dispersion Medium | Not typically used; degradation is hydrolytic, not strongly pH-driven in storage. | Critical: Storage at pH 4.5-5.5 maintains solubility & nanoparticle integrity for >6 months at 4°C. | Prevents chitosan precipitation and loss of nanoparticle structure at neutral/basic pH. | Narrow effective pH range; may not be compatible with some protein cargos. |

Table 2: Experimental Stability Data from Comparative Studies

| Formulation | Stabilization Method | Storage Condition & Duration | Key Results: Size (PDI) | Key Results: Encapsulation Efficiency (EE%) | Key Results: Protein Activity/Release Kinetics |

|---|---|---|---|---|---|

| BSA-PLGA NPs | Lyophilized with 5% Trehalose | -20°C, 24 months | 205 nm → 215 nm (PDI: 0.08 → 0.12) | 78% → 75% | Sustained release profile maintained; >90% native BSA structure. |

| BSA-PLGA NPs | Liquid suspension, no stabilizer | 4°C, 6 months | 205 nm → 450 nm (PDI: 0.08 → 0.45) | 78% → 65% | Burst release increased from 15% to 40%. |

| Insulin-Chitosan NPs | Lyophilized with 8% Sucrose | 4°C, 6 months | 150 nm → 165 nm (PDI: 0.15 → 0.2) | 85% → 80% | Hypoglycemic efficacy in model retained 95%. |

| Insulin-Chitosan NPs | Liquid, pH 5.0 acetate buffer | 4°C, 6 months | 150 nm → 170 nm (PDI: 0.15 → 0.18) | 85% → 82% | -- |

| Insulin-Chitosan NPs | Liquid, pH 7.4 PBS buffer | 4°C, 1 month | 150 nm → >1000 nm (Aggregated) | 85% → <50% | Efficacy lost. |

Experimental Protocols for Stability Assessment

Protocol 1: Standard Lyophilization of Nanoparticles with Cryoprotectants

- Nanoparticle Preparation: Synthesize PLGA or chitosan nanoparticles via double emulsion or ionic gelation, respectively. Purify via centrifugation.

- Cryoprotectant Addition: Add a sterile aqueous solution of cryoprotectant (e.g., trehalose, sucrose) to the nanoparticle dispersion to achieve a final concentration of 5-10% w/v. Mix gently for 30 minutes.

- Freezing: Aliquot the mixture into sterile lyophilization vials. Freeze at -80°C for a minimum of 4 hours or in a shell freezer with liquid nitrogen.

- Primary Drying: Transfer vials to a pre-cooled (-40°C) freeze-dryer. Apply vacuum and maintain shelf temperature at -35°C for 24-48 hours to remove ice via sublimation.

- Secondary Drying: Gradually increase shelf temperature to 25°C over 10 hours and hold for 10-12 hours to remove residual bound water.

- Sealing & Storage: Seal vials under vacuum or inert gas (N₂). Store at designated temperature.

- Reconstitution: Add original volume of sterile water or buffer, vortex gently for 30 seconds, and let stand for 5 minutes before characterization.

Protocol 2: Accelerated Stability Testing

- Sample Preparation: Prepare identical batches of stabilized (e.g., lyophilized) and unstabilized nanoparticle formulations.

- Stress Conditions: Store samples under controlled stress conditions: a) 4°C (refrigeration), b) 25°C/60% RH (room temp), c) 40°C/75% RH (accelerated). Sample at predetermined intervals (e.g., 0, 1, 3, 6 months).

- Analysis: At each time point, reconstitute lyophilized samples. Characterize:

- Size & PDI: Dynamic Light Scattering (DLS).

- Surface Charge: Zeta potential measurement.

- Entrapment Efficiency: Centrifuge/filter to separate free protein. Quantify using micro-BCA assay or HPLC.

- Morphology: TEM or SEM imaging.

- Protein Integrity: SDS-PAGE, circular dichroism, or activity assay (e.g., ELISA, enzymatic assay).

- Data Modeling: Use the Arrhenius equation to predict long-term stability at recommended storage temperatures from accelerated condition data.

Pathways and Workflows

Diagram Title: Nanoparticle Stabilization Strategy Decision Workflow

Diagram Title: Storage Stress Factors and Failure Pathways for Nanoparticles

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Nanoparticle Stability Studies

| Item | Function in Stability Research | Example Product/Chemical |

|---|---|---|

| Lyoprotectants/Cryoprotectants | Protect nanoparticles from ice crystal damage and form a stable glassy matrix during freeze-drying. | D-(+)-Trehalose dihydrate, Sucrose, Mannitol, Polyvinylpyrrolidone (PVP). |

| Controlled pH Storage Buffers | Maintain nanoparticle integrity, especially critical for chitosan (acidic pH) to prevent precipitation. | Acetate buffer (pH 4.5-5.5), Citrate buffer, Phosphate Buffered Saline (PBS). |

| Sterile Filtration Units | Aseptically process liquid formulations to remove microbes and prevent biological degradation. | 0.22 μm PVDF or cellulose acetate syringe filters. |

| Lyophilization Vials & Stoppers | Contain formulation during freeze-drying and allow for sterile sealing under vacuum/inert gas. | Glass serum vials (e.g., 2R, 6R) with lyophilization rubber stoppers. |

| Size & Zeta Potential Analyzer | Critical instrument for monitoring physical stability (hydrodynamic diameter, PDI, surface charge). | Malvern Zetasizer Nano ZS, Brookhaven ZetaPALS. |

| Protein Assay Kits | Quantify free vs. entrapped protein to calculate encapsulation efficiency (EE%) over time. | Micro BCA Protein Assay Kit, Coomassie (Bradford) Assay Kit. |

| Activity Assay Kits | Assess structural/functional integrity of the encapsulated protein cargo post-storage. | ELISA Kits, Enzymatic Activity Assays (substrate-specific). |

| Inert Sealing Gas | Displaces oxygen in storage vials to minimize oxidative degradation of polymer and protein. | Research-grade Nitrogen (N₂) or Argon gas cylinders with regulator. |

| Stability Chambers | Provide controlled temperature and humidity environments for real-time and accelerated studies. | Thermostatically controlled incubators or walk-in chambers with humidity control. |

Scaling nanocarrier synthesis from milligram research batches to kilogram Good Manufacturing Practice (GMP) production is a critical translational hurdle. This guide compares scalability pathways for Poly(lactic-co-glycolic acid) (PLGA) and chitosan nanoparticles for protein delivery, focusing on process parameters, product critical quality attributes (CQAs), and associated experimental data.

Scalability Comparison: Key Process Parameters & Outcomes

The transition from lab-scale to GMP production involves fundamental changes in mixing, purification, and process control. The table below compares the scalability profiles of two common nanoprecipitation/ionotropic gelation methods.

Table 1: Scalability Comparison of PLGA vs. Chitosan Nanoparticle Synthesis

| Parameter | Lab-Scale (PLGA) | GMP-Scale (PLGA) | Lab-Scale (Chitosan) | GMP-Scale (Chitosan) |

|---|---|---|---|---|

| Batch Size | 10-100 mg | 1-10 kg | 10-100 mg | 0.5-5 kg |

| Mixing Method | Magnetic stirrer/vortex | Static mixer/TFF in-line homogenization | Magnetic stirrer, drip addition | Dynamic in-line mixing (Tee connector) |

| Energy Input | Low, variable | High, controlled & reproducible | Low, variable | Medium, controlled |

| Process Time | 1-2 hours | 4-8 hours (including purification) | 30-45 minutes | 2-4 hours (including cross-linking) |