Mastering ASTM F1635-11: The Complete Guide to Biomaterial Degradation Testing for Researchers

This comprehensive guide demystifies ASTM F1635-11, the critical standard for evaluating in vitro degradation of poly(L-lactic acid) (PLLA) resins and their fabricated forms.

Mastering ASTM F1635-11: The Complete Guide to Biomaterial Degradation Testing for Researchers

Abstract

This comprehensive guide demystifies ASTM F1635-11, the critical standard for evaluating in vitro degradation of poly(L-lactic acid) (PLLA) resins and their fabricated forms. Tailored for researchers, scientists, and drug development professionals, we explore the standard's foundational principles, detailed methodological execution, common troubleshooting scenarios, and its validation context compared to other methods. The article provides actionable insights for accurate, reproducible testing to ensure material safety and performance, crucial for regulatory submissions and successful biomedical product development.

What is ASTM F1635-11? Demystifying the Core Standard for PLLA Degradation Testing

Within the rigorous framework of biomaterial research and development, degradation testing is not merely a regulatory checkbox but a fundamental scientific inquiry. It provides the critical data linking a material's in vitro behavior to its projected in vivo performance and safety. This guide is framed within the context of a broader thesis on ASTM F1635-11, the standard test method for in vitro degradation testing of hydrolytically degradable polymer resins and fabricated forms for surgical implants. This standard provides the foundational methodology, but its intelligent application and interpretation are paramount for researchers, scientists, and drug development professionals aiming to predict clinical outcomes.

The ASTM F1635-11 Framework: Principles and Parameters

ASTM F1635-11 prescribes a simulated physiological solution immersion test to gauge the hydrolytic degradation of materials like polylactic acid (PLA), polyglycolic acid (PGA), and their copolymers. The core principle is accelerated testing in a controlled, reproducible environment.

Key Quantitative Parameters and Outcomes

The standard mandates tracking specific quantitative measures over time. The following table summarizes the primary data outputs and their significance.

Table 1: Key Quantitative Measures in ASTM F1635-11 Degradation Testing

| Measure | Method of Analysis | Significance for Safety & Performance |

|---|---|---|

| Mass Loss (%) | Gravimetric analysis (dry mass). | Direct indicator of material resorption rate; informs implant structural lifetime. |

| Molecular Weight Loss (Mw, Mn) | Gel Permeation Chromatography (GPC). | Tracks chain scission; correlates with loss of mechanical properties. |

| pH of Immersion Medium | pH meter. | Monitors acidic degradation product accumulation; predicts inflammatory response. |

| Mechanical Properties (e.g., Tensile Strength) | Mechanical testing (per ASTM D638). | Core performance metric; defines functional window of the implant. |

| Morphology Change | Scanning Electron Microscopy (SEM). | Visualizes surface erosion, cracking, and pore formation. |

Detailed Experimental Protocol: Adhering to ASTM F1635-11

1. Sample Preparation:

- Fabricate test specimens per relevant material specifications (e.g., compression molding, machining).

- Condition specimens in a desiccator until constant mass is achieved (typically 24-48 hrs).

- Accurately weigh each specimen (initial dry mass, M₀).

- Measure initial molecular weight and mechanical properties on control samples.

2. Immersion Study Setup:

- Prepare phosphate-buffered saline (PBS, pH 7.4 ± 0.1) or another simulated physiological fluid as the immersion medium.

- Use a sufficient volume of medium to ensure sink conditions (standard recommends 10:1 volume-to-surface area ratio).

- Place individual specimens in separate vials containing the medium.

- Incubate vials in a controlled-temperature environment at 37°C ± 1°C.

3. Sampling and Analysis:

- At predetermined time points (e.g., 1, 4, 12, 26 weeks), remove replicate samples (n≥3).

- Rinsing & Drying: Rinse samples gently with deionized water and dry to constant mass under vacuum.

- Gravimetric Analysis: Weigh dried sample (Mₜ). Calculate mass loss:

((M₀ - Mₜ) / M₀) * 100%. - Medium Analysis: Record pH of the used immersion medium.

- Material Analysis: Perform GPC for molecular weight, SEM for morphology, and mechanical testing on the dried specimens.

- Statistical Analysis: Report mean and standard deviation for all quantitative measures.

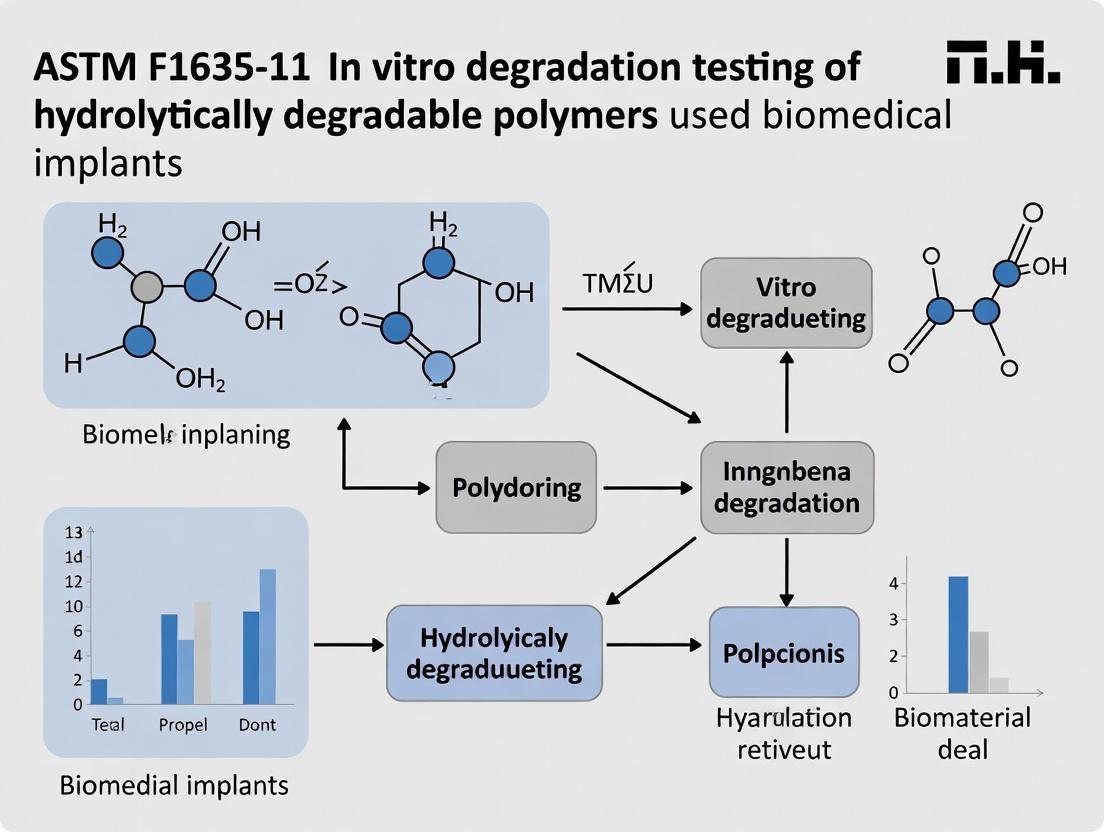

Visualizing the Degradation Cascade and Workflow

The degradation process initiates a predictable cascade of events, which the testing workflow is designed to monitor.

Diagram 1: Hydrolytic Degradation Cascade of Polyesters

Diagram 2: ASTM F1635-11 Core Experimental Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Successful degradation testing relies on precise materials and reagents.

Table 2: Essential Research Reagents & Materials for Degradation Testing

| Item | Function / Rationale |

|---|---|

| Phosphate-Buffered Saline (PBS), pH 7.4 | Simulates ionic strength and pH of physiological fluid. Sodium azide (0.02% w/v) may be added to inhibit microbial growth in long-term studies. |

| High-Purity Water (Type I, 18.2 MΩ·cm) | Used for preparing all solutions and rinsing samples to avoid contamination from ions that could catalyze degradation. |

| Reference Polymers (e.g., PLA, PGA Standards) | Well-characterized polymers with known molecular weights and dispersity for GPC calibration and as experimental controls. |

| GPC/SEC Solvents (e.g., HPLC-grade THF, Chloroform) | High-purity solvents for dissolving polymer samples and running GPC analysis without introducing artifacts. |

| pH Standard Buffers (pH 4.0, 7.0, 10.0) | For precise calibration of the pH meter before measuring the immersion medium. |

| Vacuum Desiccator & Drierite | Provides a dry, controlled environment for achieving constant mass of hygroscopic polymer samples before and after immersion. |

| Inert Sample Vials (e.g., Glass) | Prevents leaching of additives from plastic containers that could interfere with degradation chemistry or analytics. |

Advancing Beyond the Standard: CorrelatingIn VitroData toIn VivoPerformance

The ultimate goal of degradation testing is prediction. Current research focuses on refining ASTM F1635-11 protocols to better mimic in vivo conditions. This includes studying the effects of dynamic strain (mechanically active environments), protein adsorption, and enzymatic activity on degradation rates. By systematically applying the standard and thoughtfully extending its framework, researchers can generate robust data that critically informs the safety, efficacy, and design of next-generation biomaterials.

This whitepaper details the genesis, technical scope, and specific applicability of the ASTM F1635-11 standard, a pivotal benchmark for evaluating the in vitro degradation of polymeric biomaterials within a simulated physiological environment. Framed within a broader thesis on standardized biomaterial testing, this document provides researchers and development professionals with a foundational guide to the standard’s history, its rigorous experimental protocols, and its critical role in ensuring the safety and performance prediction of absorbable implants.

Genesis and Historical Context

The ASTM F1635 standard, initially published in 1995, was developed in response to the burgeoning field of absorbable polymeric medical devices (e.g., sutures, fixation devices, tissue scaffolds). Prior to its establishment, a lack of standardized in vitro methodologies led to inconsistent degradation data, hindering reliable material comparison and performance prediction. The standard was created by Committee F04 on Medical and Surgical Materials and Devices to provide a controlled, reproducible means to measure mass loss and physical property changes of polymers in a simulated physiological fluid. The 2011 revision (F1635-11) refined procedural details and precision statements, solidifying its role as a pre-clinical screening tool essential for regulatory submissions (e.g., to the FDA) and research validation.

Scope and Specific Applicability

ASTM F1635-11, titled “Standard Test Method for In Vitro Degradation Testing of Hydrolytically Degradable Polymer Resins and Fabricated Forms for Surgical Implants,” defines a specific immersion test in a phosphate-buffered solution (pH 7.4 ± 0.1) at 37°C. Its scope is intentionally focused:

- Materials: Hydrolytically degradable polymers (e.g., poly(L-lactic acid) (PLLA), poly(glycolic acid) (PGA), poly(lactic-co-glycolic acid) (PLGA), polycaprolactone (PCL)).

- Forms: Testable as solid resin specimens or in fabricated forms (e.g., molded shapes, fibers, porous scaffolds).

- Primary Measurable: Percent mass loss over time as the primary indicator of degradation.

- Key Applications:

- Quality control and lot-to-lot consistency verification.

- Comparative ranking of different polymer compositions or processing conditions.

- Providing degradation data for regulatory filings (510(k), PMA).

- Serving as a controlled baseline before complex in vivo or cell-based studies.

It is critical to note that the standard explicitly excludes testing of devices containing drugs, biologics, or ceramic fillers, and does not simulate dynamic mechanical loading or specific biological interactions (e.g., enzymatic activity).

Core Experimental Protocol

The following is the detailed methodology prescribed by ASTM F1635-11.

3.1. Reagent and Material Preparation

- Phosphate-Buffered Saline (PBS): 0.1M, pH 7.4 ± 0.1, prepared with reagent-grade chemicals and deionized water. Sodium azide (0.03% w/v) may be added to inhibit microbial growth.

- Test Specimens: A minimum of five specimens per material per time point. Specimens are cleaned, dried to constant mass in a desiccator, and precisely weighed (initial mass, M₀).

- Equipment: Incubation oven (37°C ± 1°C), analytical balance (±0.01 mg), vacuum desiccator, pH meter, and sterile containers.

3.2. Test Procedure

- Immersion: Each specimen is placed in a separate container with a PBS volume-to-specimen surface area ratio ≥ 20 mL/cm².

- Incubation: Containers are sealed and placed in the 37°C oven for predetermined time intervals (e.g., 1, 3, 6, 12, 24 weeks).

- Solution Monitoring: The pH of the PBS is checked regularly (e.g., weekly) and replaced with fresh, pre-warmed PBS if the pH shifts beyond 7.4 ± 0.2.

- Specimen Retrieval: At each time point, specimens are removed, gently rinsed with deionized water, and dried to constant mass (M_t) under vacuum desiccation.

- Mass Loss Calculation: Percent mass loss is calculated for each specimen: `[(M₀ - M_t) / M₀] x 100%.

3.3. Data Reporting and Analysis Report includes mean mass loss, standard deviation, sample size, PBS change schedule, and observations of physical changes (e.g., fragmentation, swelling). Data is typically plotted as mean mass loss (%) versus time.

Table 1: Typical Degradation Data for Common Polymers (Illustrative)

| Polymer | Initial Molecular Weight (kDa) | 12-Week Mass Loss (%) (Mean ± SD) | Time to 50% Mass Loss (Weeks, approx.) | Key Physical Change Observed |

|---|---|---|---|---|

| PGA | 100 | 85 ± 5 | 12-16 | Rapid fragmentation, pH drop |

| PLGA 50:50 | 80 | 65 ± 8 | 8-12 | Surface erosion, swelling |

| PLLA | 120 | 8 ± 3 | >52 | Slow bulk erosion, slight crystallinity increase |

| PCL | 80 | 5 ± 2 | >78 | Minimal change, ductile |

Workflow and Decision Pathway

The following diagram outlines the logical experimental workflow and decision-making process mandated by ASTM F1635-11.

ASTM F1635-11 In Vitro Degradation Testing Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

The following table details key consumables and reagents essential for conducting compliant ASTM F1635-11 testing.

Table 2: Key Research Reagent Solutions for ASTM F1635-11 Testing

| Item | Function & Specification | Critical Notes |

|---|---|---|

| Phosphate Buffered Saline (PBS) | Simulates ionic strength and pH of physiological fluid. 0.1M, pH 7.4 ± 0.1. | Must be sterile-filtered. Addition of 0.03% sodium azide is recommended for long-term studies to prevent microbial growth. |

| Sodium Azide (NaN₃) | Bacteriostatic agent to maintain sterility in the immersion medium. | Handle with care; toxic. Low concentration does not significantly affect hydrolysis kinetics. |

| Desiccant (e.g., Drierite) | Creates a dry environment in a desiccator for drying specimens to constant mass. | Must be regularly regenerated or replaced to ensure effective drying. |

| Vacuum Pump / Desiccator | Removes residual moisture from specimens post-retrieval prior to weighing. | Essential for achieving "constant mass," defined as < ±0.1 mg change over 24h drying. |

| Analytical Microbalance | Precisely measures specimen mass (accuracy ±0.01 mg or better). | Calibration must be current and traceable to standard weights. |

| pH Meter & Buffers | Monitors and verifies the pH of the PBS before and during incubation. | Regular calibration with pH 4.01, 7.00, and 10.01 buffers is mandatory. |

| Sterile Sealed Containers | Holds individual specimen-PBS systems, prevents evaporation and contamination. | Polypropylene or glass are suitable. Must be inert and not adsorb degradation products. |

| Oven / Incubator | Maintains constant temperature at 37°C ± 1°C. | Forced air circulation is preferred to ensure uniform temperature distribution. |

ASTM F1635-11, "Standard Test Method for in vitro Degradation Testing of Hydrolytically Degradable Polymer Resins and Fabricated Forms for Surgical Implants," provides the critical framework for evaluating absorbable polymers in biomedical applications. This whitepaper deconstructs the core terminology and measurement principles underpinning this standard, focusing on hydrolytic degradation, molecular weight changes, and mass loss. Understanding the interrelationship of these parameters is essential for researchers and drug development professionals to predict in vivo performance, device longevity, and biocompatibility.

Core Definitions

Hydrolytic Degradation: The chain scission process by which polymer main chains are cleaved via reaction with water, leading to a reduction in molecular weight and eventual loss of mass. This is the primary degradation mechanism for many biomedical polymers (e.g., poly(lactic-co-glycolic acid) [PLGA], polycaprolactone [PCL]). The rate is influenced by polymer chemistry, crystallinity, device geometry, and environmental pH.

Molecular Weight (Mw, Mn): A measure of the size of polymer chains. Weight-average molecular weight (Mw) and number-average molecular weight (Mn) are critical metrics. Degradation is initially manifested as a decrease in Mw and Mn due to chain scission, often measured via Gel Permeation Chromatography (GPC).

Mass Loss: The physical loss of material from a specimen as degradation byproducts (oligomers and monomers) become soluble and diffuse into the surrounding aqueous medium. Mass loss typically follows the initial drop in molecular weight.

Table 1: Typical Degradation Timeline for Common Bioabsorbable Polymers

| Polymer | Time to 50% Mw Loss (weeks) | Time to Onset of Mass Loss (weeks) | Time to Complete Mass Loss (weeks) | Key Influencing Factor |

|---|---|---|---|---|

| Poly(L-lactic acid) (PLLA) | 24-52 | 40-78 | 78-156 | High crystallinity slows hydrolysis |

| Poly(D,L-lactic acid) (PDLLA) | 12-24 | 18-36 | 36-52 | Amorphous structure accelerates process |

| 50:50 Poly(lactic-co-glycolic acid) (PLGA) | 4-8 | 5-10 | 10-16 | High glycolide content increases hydrophilicity |

| Poly(glycolic acid) (PGA) | 2-4 | 3-6 | 6-12 | Highly crystalline but hydrophilic |

| Polycaprolactone (PCL) | >104 | >156 | >208 | High hydrophobicity slows degradation |

Table 2: Key Analytical Methods per ASTM F1635-11 Guidance

| Parameter | Primary Test Method | Sample Requirement | Key Output Metrics |

|---|---|---|---|

| Molecular Weight Change | Gel Permeation Chromatography (GPC) | 2-5 mg dissolved in suitable solvent | Mw, Mn, Polydispersity Index (PDI) |

| Mass Loss | Gravimetric Analysis | Dry mass pre- and post-incubation | Percentage mass remaining |

| Thermal Properties | Differential Scanning Calorimetry (DSC) | 3-10 mg | Glass Transition (Tg), Melting Temp (Tm), Crystallinity (%) |

| Morphology | Scanning Electron Microscopy (SEM) | Coated specimen | Surface erosion vs. bulk erosion patterns |

Experimental Protocols

Protocol 1: Standard in vitro Hydrolytic Degradation Study (ASTM F1635-11 Based)

- Specimen Preparation: Fabricate test specimens (e.g., discs, films) to specified dimensions (e.g., 10 mm diameter x 1 mm thick). Dry in a vacuum desiccator to constant mass (M₀). Record initial dry mass.

- Molecular Weight Baseline: Determine initial Mw and Mn for a subset of samples using GPC.

- Immersion: Place individual specimens in vials containing a buffered solution (commonly phosphate-buffered saline [PBS] at pH 7.4 ± 0.1). Maintain a standard volume-to-surface area ratio (e.g., 1 mL per 20 mm²). Seal vials.

- Incubation: Place vials in a controlled-temperature environment (37°C ± 1°C).

- Sample Retrieval & Analysis: At predetermined time points (e.g., 1, 2, 4, 8, 12, 26 weeks):

- Remove specimen, rinse with deionized water, and dry to constant mass (Mₜ). Calculate mass loss: % Mass Remaining = (Mₜ / M₀) * 100.

- Analyze molecular weight via GPC on the dried sample.

- Optionally, analyze thermal properties (DSC) and surface morphology (SEM).

- Buffer Management: The immersion medium should be replaced periodically (e.g., weekly) to maintain pH and avoid saturation of degradation products.

Protocol 2: Gel Permeation Chromatography (GPC) for Molecular Weight Determination

- Sample Preparation: Dissolve the dried polymer specimen (approx. 2 mg) in the GPC eluent (e.g., Tetrahydrofuran [THF] for PLGA, Chloroform for PCL) at a known concentration (∼1 mg/mL). Filter through a 0.2 μm PTFE syringe filter.

- System Calibration: Create a calibration curve using narrow dispersity polystyrene (PS) or polymethyl methacrylate (PMMA) standards of known molecular weights.

- Chromatography: Inject sample into the GPC system (pump, columns, detector – typically refractive index [RI]). Use a constant flow rate (e.g., 1.0 mL/min).

- Data Analysis: Use specialized software to calculate Mw, Mn, and PDI from the chromatogram by comparing retention times to the calibration curve.

Diagrams

Hydrolytic Degradation Pathway

ASTM F1635-11 Test Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Hydrolytic Degradation Studies

| Item | Function | Example/Notes |

|---|---|---|

| Phosphate Buffered Saline (PBS) | Standard immersion medium simulating physiological pH and ionic strength. | 10x PBS concentrate, pH 7.4, sterile filtered. |

| GPC/SEC System with RI Detector | Absolute determination of molecular weight averages and distribution. | Systems from Agilent, Waters, or Malvern; requires appropriate columns. |

| GPC/SEC Standards | Calibration of the GPC system for accurate molecular weight calculation. | Narrow dispersity Polystyrene (PS) or PMMA standards. |

| Analytical Balance (Micro) | Precise gravimetric measurement of mass loss (to 0.01 mg). | Essential for tracking small mass changes over time. |

| Vacuum Oven/Desiccator | Drying specimens to constant mass before and after incubation. | Maintains dry environment; use with phosphorus pentoxide or silica gel. |

| pH Meter & Buffer Solutions | Regular monitoring and adjustment of immersion medium pH. | Critical as acidic degradation products can autocatalyze hydrolysis. |

| 0.2 μm PTFE Syringe Filters | Filtering polymer solutions for GPC analysis to remove particulates. | Prevents column damage and ensures accurate chromatograms. |

| Appropriate HPLC-grade Solvents | Dissolving polymers for GPC analysis (specific to polymer chemistry). | THF (for PLGA, PGA), Chloroform (for PCL, PLLA), Hexafluoroisopropanol (for some polyesters). |

| Controlled Temperature Incubator | Maintaining physiological temperature (37°C) for incubation. | Stable temperature (±1°C) is crucial for reproducible kinetics. |

Within the rigorous framework of biomaterials research and development, particularly for implantable medical devices, the evaluation of degradation behavior is non-negotiable. ASTM F1635-11, "Standard Test Method for in vitro Degradation Testing of Hydrolytically Degradable Polymer Resins and Fabricated Forms for Surgical Implants," provides the critical methodology for this assessment. Its essentiality for regulatory submissions to agencies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) stems from its role in establishing standardized, reproducible, and predictive data on material performance, which directly correlates to safety and efficacy endpoints required by regulators.

The Role of Standardization in Regulatory Science

Regulatory agencies mandate that medical device submissions demonstrate substantial equivalence (for 510(k)) or safety and effectiveness (for PMA). A core component of this demonstration for degradable materials, such as those used in orthopedic fixation devices, sutures, and drug-eluting scaffolds, is a comprehensive understanding of their degradation profile. ASTM F1635-11 provides the standardized "language" and experimental framework to generate this data.

- Predictability: It offers a controlled in vitro model to predict in vivo degradation rates and modes, informing preclinical study design.

- Reproducibility: The standard minimizes inter-laboratory variability, ensuring data submitted by sponsors is reliable and auditable.

- Risk Mitigation: By identifying potential failure modes (e.g., rapid loss of mechanical strength, unexpected byproduct release) early, it guides material selection and device design, reducing clinical risk.

Core Technical Protocols of ASTM F1635-11

The standard outlines specific methodologies for sample preparation, conditioning, and analysis.

Key Experimental Protocol: Mass Loss and Molecular Weight Change

This is the primary quantitative method for tracking degradation.

- Sample Preparation: Specimens are cut to specified dimensions (e.g., 10 mm x 10 mm x 1 mm), cleaned, and dried to constant mass.

- Initial Characterization: Initial dry mass (M₀) is recorded. Initial molecular weight (Mₙ₀ and/or Mᵥ₀) is determined via Gel Permeation Chromatography (GPLC).

- Immersion: Specimens are immersed in a phosphate-buffered saline (PBS) solution (pH 7.4 ± 0.1) at 37°C ± 1°C. The solution volume-to-sample surface area ratio is maintained (≥ 20 mL/cm²) to ensure sink conditions.

- Time-Point Sampling: Triplicate specimens are removed at predetermined time points (e.g., 1, 4, 12, 26, 52 weeks).

- Analysis: Retrieved samples are rinsed, dried to constant mass, and weighed (Mₜ). Mass loss percentage is calculated. Molecular weight (Mₙₜ) is determined via GPLC.

- Solution Analysis: The immersion medium is analyzed for pH change and the release of degradation products (e.g., lactic acid, glycolic acid) via High-Performance Liquid Chromatography (HPLC).

Data Presentation: Simulated Degradation Data for PLA (Poly(L-lactic acid))

The following table summarizes typical data generated per ASTM F1635-11, crucial for an Investigational Device Exemption (IDE) or marketing application.

Table 1: In Vitro Degradation Profile of PLA (97% Crystalline) per ASTM F1635-11

| Time Point (Weeks) | Mass Remaining (%) | Mₙ Retention (%) | pH of Immersion Medium | Notable Observations |

|---|---|---|---|---|

| 0 | 100.0 ± 0.5 | 100.0 ± 3.0 | 7.40 ± 0.05 | - |

| 4 | 99.5 ± 0.7 | 85.2 ± 4.1 | 7.38 ± 0.05 | No visible change |

| 12 | 98.1 ± 1.0 | 62.3 ± 5.5 | 7.30 ± 0.08 | Slight surface erosion |

| 26 | 92.4 ± 2.3 | 28.5 ± 6.7 | 7.15 ± 0.12 | Significant loss of tensile strength |

| 52 | 75.8 ± 5.6 | 10.1 ± 3.2 | 6.95 ± 0.20 | Fragmentation begins |

Table 2: Key Research Reagent Solutions for ASTM F1635-11 Testing

| Item Name | Function / Rationale |

|---|---|

| Phosphate Buffered Saline (PBS), pH 7.4 | Simulates physiological ionic strength and pH; the primary immersion medium for hydrolytic degradation. |

| Sodium Azide (0.02% w/v) | Added to PBS to inhibit microbial growth during long-term studies, preventing confounding mass loss. |

| HPLC-Grade Water | For rinsing samples and preparing mobile phases for GPLC/HPLC analysis to avoid contaminants. |

| Polystyrene Standards | Used for calibrating the GPLC system to determine accurate molecular weight distributions. |

| Certified Reference Materials (e.g., Lactic Acid) | Used as standards for HPLC calibration to quantify degradation byproducts in solution. |

Regulatory Submission Mapping

Data generated under ASTM F1635-11 directly informs critical sections of regulatory dossiers:

- FDA Pre-Submission & 510(k)/PMA: Demonstrates biocompatibility (per ISO 10993-13: Identification and Quantification of Degradation Products) and provides engineering performance data.

- EMA Technical Documentation (Annex II of MDR): Supports the "Design and Manufacturing Information" and "Risk Management File" by providing validated methods for verifying material safety.

- Common Ground: Both agencies require a justification of test conditions (e.g., buffer choice, temperature), raw data, statistical analysis, and a discussion linking in vitro results to projected in vivo performance and potential biological responses.

Diagram: ASTM F1635-11 Workflow in Regulatory Pathway

ASTM F1635-11 is not merely a recommended test but a foundational pillar for the regulatory approval of hydrolytically degradable medical devices. Its precise protocols generate the quantitative, comparable, and auditable data that FDA and EMA reviewers rely upon to assess the critical quality attribute of degradation. By adhering to this standard, researchers and sponsors provide robust scientific evidence that bridges material science, preclinical research, and clinical safety, thereby facilitating a more efficient and predictable regulatory review process.

ASTM F1635-11, "Standard Test Method for in vitro Degradation Testing of Hydrolytically Degradable Polymer Resins and Fabricated Forms for Surgical Implants," provides a critical framework for evaluating polymers like Poly(L-lactic acid) (PLLA). This guide details the application of this standard to PLLA in its various forms—raw resin, engineered scaffolds, and final implantable devices. The standard's focus on mass loss, molecular weight change, and mechanical property decay under simulated physiological conditions is paramount for predicting in vivo performance and ensuring patient safety.

PLLA Degradation Mechanisms & Pathways

PLLA undergoes bulk erosion primarily via hydrolysis of its ester backbone. The process is autocatalytic, as acidic degradation products (lactic acid oligomers and monomers) accelerate further chain scission.

Diagram 1: PLLA Hydrolytic Degradation Pathway

Core Experimental Protocols per ASTM F1635-11

Specimen Preparation & Conditioning

- Materials: PLLA resin (e.g., 100 kDa), compression molding press, ISO phosphate-buffered saline (PBS), desiccator.

- Protocol: Fabricate standard dumbbell (Type V) or rectangular specimens. Condition specimens in a desiccator at 37°C to constant weight (dry mass, W₀). Record initial dimensions.

In VitroDegradation Study

- Incubation Medium: Pre-heated PBS (pH 7.4 ± 0.1) or PBS with 0.02% sodium azide to prevent microbial growth.

- Temperature: 37 ± 1°C (water bath or oven).

- Volume-to-Surface Area Ratio: As per standard, typically ≥ 20 mL per cm² specimen surface area.

- Time Points: 0, 1, 2, 4, 8, 12, 16, 26, 52 weeks. Medium should be replaced at each measurement interval to maintain pH and sink conditions.

- Triplicates: Minimum n=3 per time point.

Key Measurements at Each Time Point

- Mass Loss: Retrieve specimens, rinse with deionized water, dry to constant mass (Wₜ). Calculate percentage mass loss:

[(W₀ - Wₜ) / W₀] × 100. - Molecular Weight: Analyze dried specimens via Gel Permeation Chromatography (GPC) against polystyrene standards. Report Mₙ (number average) and Mᵥ (weight average).

- Thermal Properties: Use Differential Scanning Calorimetry (DSC) to determine glass transition (Tg), cold crystallization (Tcc), and melt temperatures (Tm), and percent crystallinity.

- Mechanical Properties (for scaffolds/implants): Perform tensile or compressive testing per ASTM D638 or D695. Report modulus, ultimate strength, and elongation at break.

Table 1: Representative *In Vitro Degradation Data for PLLA (100 kDa, amorphous, 37°C, PBS)*

| Time (Weeks) | Mass Loss (%) | Mᵥ (kDa) | Crystallinity (%) | Tensile Strength Retention (%) |

|---|---|---|---|---|

| 0 | 0.0 | 100.0 | 5 | 100 |

| 4 | < 0.5 | 85.2 | 8 | 98 |

| 12 | 1.2 | 65.7 | 15 | 92 |

| 26 | 3.8 | 40.1 | 25 | 75 |

| 52 | 12.5 | 18.9 | 32 | 45 |

Table 2: Impact of PLLA Form on Degradation Kinetics (at 26 weeks)

| PLLA Form | Initial Mᵥ (kDa) | Mass Loss (%) | Key Feature Influencing Rate |

|---|---|---|---|

| Solid Resin Disk | 100 | 3.8 | Low surface area, bulk erosion |

| Porous Scaffold | 100 | 15.2 | High porosity increases SA:V |

| Suture Fiber | 100 | 8.5 | High orientation, higher crystallinity slows hydrolysis |

| Nanoparticle | 100 | > 90* | Extremely high surface area |

Note: Nanoparticles may be fully degraded/resorbed by this time point.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for PLLA Degradation Research

| Item/Catalog Example | Function in Protocol |

|---|---|

| High-Purity PLLA Resin (e.g., Lacty, PURASORB) | Primary test material with defined initial molecular weight and D-isomer content. |

| Phosphate Buffered Saline (PBS), pH 7.4 | Simulates physiological ionic strength and pH for hydrolytic degradation. |

| Sodium Azide (NaN₃), 0.02% w/v | Bacteriostatic agent added to PBS to prevent microbial growth in long-term studies. |

| GPC/SEC System with Refractive Index Detector | Analyzes molecular weight distribution and average Mᵥ/Mₙ over time. |

| Differential Scanning Calorimeter (DSC) | Tracks thermal property changes (Tg, crystallinity) indicating chain mobility and degradation. |

| ISO 37 Type V Dumbbell Cutting Die | Standardizes specimen geometry for reproducible mechanical and degradation testing. |

| Vacuum Desiccator with Drierite | Conditions specimens to a constant dry mass (W₀) before and during the study. |

Diagram 2: ASTM F1635-11 PLLA Test Workflow

Considerations for Specific PLLA Forms

- Resins: Characterize inherent viscosity and residual monomer content per ASTM D2857.

- Scaffolds: Porosity (measured via mercury intrusion porosimetry or micro-CT) and pore architecture significantly accelerate degradation. Monitor dimensional stability.

- Implantable Devices (e.g., screws, meshes): Sterilization method (gamma irradiation, ethylene oxide) can affect initial Mw and degradation onset. Test final sterilized form.

Rigorous application of ASTM F1635-11 to PLLA materials provides predictive, comparable data essential for regulatory submissions and clinical translation. Understanding the interplay between material form, morphology, and degradation kinetics is critical for designing safe and effective resorbable medical devices.

Within the context of biomaterials research and development, the prediction of long-term in vivo performance is paramount. ASTM F1635-11, "Standard Test Method for In Vitro Degradation Testing of Hydrolytically Degradable Polymer Resins and Fabricated Forms for Surgical Implants," provides a critical framework. This whitepaper details the fundamental scientific principles and methodologies underlying simulated in vitro hydrolytic degradation, a core component of compliant testing, serving researchers and drug development professionals engaged in evaluating absorbable polymers for medical devices.

Core Scientific Principles

Hydrolytic degradation of polymers, particularly polyesters like poly(lactic-co-glycolic acid) (PLGA), poly(L-lactic acid) (PLLA), and poly(glycolic acid) (PGA), proceeds via the cleavage of hydrolytically labile ester bonds in the polymer backbone. The process is governed by several interconnected factors:

- Water Absorption: The initial ingress of aqueous medium into the polymer matrix.

- Ester Bond Hydrolysis: The nucleophilic attack by water molecules, leading to chain scission. This can be autocatalytic due to the generation of acidic carboxyl end groups.

- Diffusion-Controlled Kinetics: The rate of degradation is often controlled by the diffusion of water in and oligomers/acidic by-products out of the polymer bulk.

- Crystallinity & Morphology: Amorphous regions degrade faster than crystalline ones, affecting the overall degradation profile and mechanical integrity loss.

The autocatalytic effect is a hallmark of bulk-eroding polymers. As degradation proceeds internally, acidic monomers and oligomers become trapped, lowering the local pH and accelerating ester hydrolysis in the core, often leading to faster internal degradation than at the surface.

Methodologies & Protocols Aligned with ASTM F1635-11

ASTM F1635-11 outlines standardized conditions for reproducible testing. Key experimental parameters and detailed protocols are summarized below.

Standard Test Conditions & Data

The standard specifies using phosphate-buffered saline (PBS, pH 7.4 ± 0.1) at 37 ± 1°C to simulate physiological conditions. Agitation is recommended. Testing duration should be sufficient to characterize the degradation profile.

Table 1: Key Quantitative Parameters Monitored During In Vitro Hydrolytic Degradation Testing

| Parameter | Measurement Technique | Significance | Typical Data Range (e.g., PLGA 50:50) |

|---|---|---|---|

| Mass Loss (%) | Gravimetric Analysis | Direct indicator of material dissolution and erosion. | 0% (initial) to >80% (complete erosion) over weeks. |

| Molecular Weight Loss (Mw, Mn) | Gel Permeation Chromatography (GPC) | Tracks chain scission, precedes mass loss. | Mw can decrease to 50% of initial within 2-4 weeks. |

| pH of Degradation Medium | pH Meter | Monitors acidic by-product release; indicates autocatalysis. | PBS pH may drop to ~6.8 near polymer surface/inside pores. |

| Water Absorption (%) | Gravimetric Analysis | Indicates hydrophilicity and swelling capacity. | Can increase by 5-20% before significant mass loss. |

| Mechanical Properties (Tensile/Shear) | Mechanical Tester | Critical for load-bearing implant functionality. | Strength loss often correlates with molecular weight drop. |

Detailed Experimental Protocol

Title: Protocol for Simulated In Vitro Hydrolytic Degradation per ASTM F1635-11 Guidelines

Materials: Polymer specimens (e.g., discs, films), Phosphate Buffered Saline (PBS, 0.1M, pH 7.4), Sodium azide (0.02% w/v), Analytical balance (±0.01 mg), Oven (37°C), Agitating incubator or water bath, Filter papers, Desiccator.

Procedure:

- Specimen Preparation: Cut or mold polymer into standardized specimens (e.g., 10 mm diameter x 1 mm thick discs). Measure initial dimensions.

- Drying: Dry specimens to constant mass (M₀) in a vacuum desiccator.

- Degradation Setup: Place each specimen in a sealed vial containing a pre-warmed (37°C) PBS solution with 0.02% sodium azide to inhibit microbial growth. Use a volume-to-surface area ratio ≥20 mL/cm² as per standard.

- Incubation: Place vials in an incubator or agitating water bath at 37 ± 1°C.

- Sampling: At predetermined time points (e.g., 1, 2, 4, 8, 12, 16 weeks), remove triplicate specimens from the medium.

- Rinsing & Drying: Rinse retrieved specimens with deionized water and dry to constant mass (Mₜ) in a vacuum desiccator.

- Analysis: Calculate mass loss:

((M₀ - Mₜ) / M₀) x 100%. Analyze specimens via GPC, SEM, etc. - Medium Analysis: Monitor pH of the remaining degradation medium at each time point.

Visualizing Key Processes

Diagram 1: Hydrolytic Degradation & Autocatalysis Pathway

Diagram 2: In Vitro Degradation Testing Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Simulated Hydrolytic Degradation Studies

| Item | Function & Rationale |

|---|---|

| Phosphate Buffered Saline (PBS), 0.1M, pH 7.4 | Simulates physiological ionic strength and pH; maintains osmolarity. |

| Sodium Azide (NaN₃), 0.02% w/v | Bacteriostatic agent added to PBS to prevent microbial growth during long-term studies, ensuring mass loss is due to hydrolysis. |

| High-Purity Water (Type I) | Used for preparing buffers and rinsing specimens to avoid contamination from ions or organics. |

| Characterized Polymer Resin (e.g., PLGA) | Polymer with known initial molecular weight, lactide:glycolide ratio, crystallinity, and end-group chemistry. |

| pH Standard Buffers (4.0, 7.0, 10.0) | For precise calibration of pH meters to accurately track acidification of degradation medium. |

| Molecular Weight Standards (e.g., Polystyrene, PMMA) | Essential for calibrating Gel Permeation Chromatography (GPC) systems to determine polymer Mn, Mw, and PDI over time. |

Step-by-Step Protocol: Executing ASTM F1635-11 Degradation Testing in Your Lab

1.0 Introduction within the Context of ASTM F1635-11 The ASTM F1635-11 standard, "Standard Test Method for in vitro Degradation Testing of Hydrolytically Degradable Polymer Resins and Fabricated Forms for Surgical Implants," provides the critical framework for evaluating the degradation of biomaterials intended for clinical use. The precision, reproducibility, and biological relevance of the entire degradation study hinge upon the rigor of pre-test preparation. This phase, encompassing sample sizing, conditioning, and initial characterization, establishes the baseline from which all degradation metrics (mass loss, molecular weight decline, mechanical property changes) are measured. Inadequate preparation can introduce significant variability, obscuring true material performance and compromising adherence to the standard's requirements for specimen consistency.

2.0 Core Pre-Test Protocols

2.1 Sample Sizing and Fabrication Specimen dimensions are dictated by the subsequent analytical techniques and must be machined or molded with high precision to minimize inter-specimen variance.

Protocol:

- Material Form: For compression-molded sheets or extruded rods, ensure the bulk material is free of visible defects.

- Cutting/Machining: Use a precision die cutter (for sheets) or a lathe/milling machine (for rods) with sharp, clean tools. Cutting fluids must be non-reactive with the polymer (e.g., use chilled air or a biocompatible lubricant).

- Deburring: Carefully remove all burrs and rough edges using fine-grit sandpaper (e.g., 600-grit) or a precision blade.

- Cleaning: Ultricate specimens in a sequence of two solvents: first a non-polar solvent (e.g., hexane) to remove machining oils, followed by a polar solvent (e.g., ethanol or isopropanol). Duration: 10 minutes per solvent bath.

- Drying: Vacuum-dry specimens at ambient temperature (or below the polymer's glass transition temperature) to a constant mass. Record this as the initial dry mass (m₀).

2.2 Sample Conditioning & Hydration ASTM F1635-11 requires testing in a simulated physiological fluid (e.g., phosphate-buffered saline, PBS, pH 7.4 ± 0.2 at 37°C). Pre-hydration establishes a consistent starting state for hydrolysis.

Protocol:

- Sterilization (if required): Perform sterilization (e.g., ethylene oxide, gamma irradiation) according to the intended clinical pathway. Document the method and parameters.

- Hydration: Immerse pre-weighed, sterile specimens in degassed PBS (0.1M, pH 7.4) and place in an incubator at 37°C ± 1°C.

- Equilibration: Soak for 24-72 hours (duration must be validated for the specific polymer to reach full hydration equilibrium).

- Pat-Drying: Remove specimens, gently blot with a lint-free laboratory wipe to remove surface droplets, and immediately weigh to obtain the hydrated mass (mₕ). This step precedes initial characterization for dimensional and mass metrics.

2.3 Initial Characterization

2.3.1 Molecular Weight (Mw) Analysis via Gel Permeation Chromatography (GPC) Protocol:

- Sample Preparation: Dissolve a representative, pre-dried specimen (~5 mg) in the appropriate GPC solvent (e.g., THF for PLGA, HFIP for polyesters) at a known concentration (~2 mg/mL). Filter through a 0.2 µm PTFE syringe filter.

- System Calibration: Use a narrow dispersity polystyrene (or polymer-specific) standard calibration curve.

- Run Parameters: Inject 100 µL of sample. Use a refractive index detector. Set flow rate to 1.0 mL/min. Column temperature at 35°C.

- Data Analysis: Calculate number-average (Mn), weight-average (Mw), and polydispersity index (PDI = Mw/Mn) using the instrument's software relative to the calibration curve.

2.3.2 Dimensional Analysis Protocol:

- Tools: Use a digital micrometer (accuracy ± 0.001 mm) for thickness/diameter and a digital caliper for length/width.

- Measurement: For rectangular specimens, measure length, width, and thickness at three distinct points along each dimension. For cylindrical specimens, measure diameter at three points and length.

- Calculation: Record the mean and standard deviation. Calculate initial volume (V₀) using appropriate geometric formulae.

2.3.3 Mass Analysis Protocol:

- Instrument: Use a calibrated analytical balance with a readability of at least 0.01 mg.

- Weighing: Weigh specimens in their conditioned (hydrated, patted-dry) state (mₕ) and after thorough vacuum-drying (m₀).

- Calculation: Determine the water uptake percentage at t=0: % Water Uptake = [(mₕ - m₀) / m₀] x 100.

3.0 Data Presentation: Summary of Quantitative Baseline Metrics

Table 1: Representative Initial Characterization Data for a Hypothetical PLGA 85:15 Specimen

| Characteristic | Measurement Method | Typical Value (Mean ± SD) | ASTM F1635-11 Relevance |

|---|---|---|---|

| Initial Dry Mass (m₀) | Analytical Balance | 100.50 ± 0.25 mg | Baseline for normalized mass loss (%) calculation. |

| Initial Hydrated Mass (mₕ) | Analytical Balance | 102.30 ± 0.30 mg | Starting point for in situ mass tracking. |

| Initial Water Uptake (%) | Calculated from m₀ & mₕ | 1.79 ± 0.15 % | Indicator of initial hydrophilicity/porosity. |

| Dimensions (Rectangular) | Digital Micrometer/Caliper | 10.00 x 5.00 x 2.00 mm ± 0.05 mm | Defines surface-area-to-volume ratio, a critical driver of degradation rate. |

| Initial Mw | Gel Permeation Chromatography | 95.5 ± 2.5 kDa | Critical baseline for tracking chain scission via hydrolysis. |

| Initial PDI | Gel Permeation Chromatography | 1.65 ± 0.05 | Indicates initial molecular weight distribution breadth. |

4.0 The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 2: Essential Materials for Pre-Test Preparation per ASTM F1635-11

| Item | Function / Rationale |

|---|---|

| Precision Die Cutter / CNC Mill | Ensures specimen dimensional consistency, minimizing inter-specimen variability in surface area and volume. |

| Fine-Grit Sandpaper (600-grit) | For deburring and smoothing edges to prevent stress concentrations and ensure uniform degradation. |

| Ultrasonic Cleaning Bath | For thorough, reproducible removal of machining contaminants and particles using solvent sequences. |

| High-Purity Solvents (Hexane, Ethanol) | Non-polar and polar solvents for effective, staged cleaning without swelling/degrading the polymer. |

| Vacuum Desiccator | For drying specimens to a constant mass at non-degradative temperatures prior to initial weighing. |

| Analytical Balance (± 0.01 mg) | Provides the precision required for accurate measurement of initial mass and subtle mass changes during degradation. |

| Digital Micrometer (± 0.001 mm) | Enables high-precision measurement of critical small dimensions (e.g., thickness) for volume/SA calculations. |

| pH-Meter & Buffering Salts | To prepare and verify the pH (7.4 ± 0.2) of the phosphate-buffered saline (PBS) degradation medium. |

| Degassing Chamber / Sonicator | To remove dissolved gases from PBS, preventing bubble formation on specimens during incubation. |

| GPC/SEC System with RI Detector | The gold-standard for quantifying initial molecular weight and tracking its change over time. |

| Polymer-Appropriate GPC Standards | (e.g., Polystyrene, PMMA) Essential for generating a calibration curve to determine absolute Mw. |

| 0.2 µm PTFE Syringe Filters | For filtering GPC sample solutions to prevent column contamination by particulates or gel particles. |

5.0 Visualized Workflows

Title: Pre-Test Sample Preparation and Characterization Workflow

Title: Gel Permeation Chromatography (GPC) Protocol Flow

ASTM F1635-11, “Standard Test Method for in Vitro Degradation Testing of Hydrolytically Degradable Polymer Resins and Fabricated Forms for Surgical Implants,” specifies the use of a simulated physiological fluid as an immersion medium to study mass loss and molecular weight changes. Phosphate Buffered Saline (PBS) at pH 7.4 is a ubiquitous choice due to its isotonicity, pH stability, and ionic composition mimicking extracellular fluid. This whitepaper details the rigorous preparation and standardization of PBS to ensure consistency and reproducibility in biomaterial degradation research, a critical prerequisite for generating reliable data compliant with ASTM F1635-11.

Preparation of 1X PBS (pH 7.4)

A standard 1X PBS solution contains 137 mM Sodium Chloride (NaCl), 10 mM Phosphate, and 2.7 mM Potassium Chloride (KCl). The following protocol is for preparing 1 liter.

Reagents:

- Sodium chloride (NaCl), molecular weight: 58.44 g/mol

- Potassium chloride (KCl), molecular weight: 74.55 g/mol

- Disodium hydrogen phosphate (Na₂HPO₄), molecular weight: 141.96 g/mol (anhydrous) or 177.99 g/mol (dihydrate)

- Potassium dihydrogen phosphate (KH₂PO₄), molecular weight: 136.09 g/mol

- Reagent-grade water (Type I, deionized)

- Hydrochloric acid (HCl), 1M solution (for pH adjustment)

- Sodium hydroxide (NaOH), 1M solution (for pH adjustment)

Protocol:

- Weighing: Accurately weigh the following salts and transfer to a 1L volumetric flask:

- 8.00 g of NaCl

- 0.20 g of KCl

- 1.44 g of Na₂HPO₄ (anhydrous) or 1.78 g of Na₂HPO₄·2H₂O

- 0.24 g of KH₂PO₄

- Dissolution: Add approximately 800 mL of deionized water to the flask and stir on a magnetic stirrer until all salts are completely dissolved.

- pH Adjustment: Measure the pH using a calibrated pH meter. The pH is typically near 7.4. If adjustment is required, use drops of 1M HCl to lower the pH or 1M NaOH to raise it. Stir thoroughly after each addition.

- Final Volume: Bring the final volume to 1.0 L with deionized water.

- Sterilization (if required): For degradation studies requiring aseptic conditions, filter-sterilize the solution using a 0.22 µm membrane filter into a sterile container. Autoclaving (121°C, 15 psi, 20 minutes) is an alternative but may cause precipitation in some formulations; filter sterilization is preferred.

- Storage: Store at room temperature or 4°C. Label with preparation date, pH, and molarity.

Standardization and Quality Control

For ASTM F1635-11 compliance, the immersion medium must be characterized. The following parameters should be verified.

Table 1: Standardization Parameters for PBS (pH 7.4)

| Parameter | Target Specification | Test Method | Acceptable Range |

|---|---|---|---|

| pH | 7.40 | Potentiometry using calibrated pH meter | 7.35 - 7.45 |

| Osmolality | ~290 mOsm/kg | Freezing-point depression osmometer | 285 - 310 mOsm/kg |

| Conductivity | ~15.9 mS/cm (25°C) | Conductivity meter | 15.0 - 16.5 mS/cm |

| Absence of Contaminants | Visual clarity | Visual inspection | Clear, colorless, particle-free |

Experimental Protocol for Osmolality Measurement:

- Calibrate the osmometer using standard solutions per manufacturer instructions.

- Pipette 50 µL of the prepared PBS into a clean sample cup.

- Lower the measuring probe and initiate the reading.

- Record the value in mOsm/kg. Perform in triplicate.

Application as an Immersion Medium in ASTM F1635-11

The standard specifies immersion in a controlled buffer at 37°C. PBS serves as the hydrolytic medium, and its standardization is crucial for inter-laboratory comparison.

Experimental Protocol for Degradation Testing (Excerpt):

- Sample Preparation: Pre-weigh (W₀) and dimensionally characterize test specimens (e.g., discs, films).

- Immersion: Place each specimen in a sealed container with a defined volume of PBS (e.g., 20 mL per 100 mg polymer) to ensure sufficient sink conditions.

- Incubation: Place containers in a forced-air oven or water bath maintained at 37.0 ± 1.0°C for the duration of the study (e.g., 1, 3, 6, 12 months).

- Medium Management: The PBS immersion medium should be replaced periodically (e.g., weekly) to maintain pH and ion concentration, as degradation products can alter the local environment.

- Analysis: At designated time points, remove specimens, rinse, dry under vacuum, and analyze for mass loss (Wₜ), molecular weight (GPC), and visual/microscopic changes.

Logical Workflow for PBS Preparation & Use in ASTM Testing

The Scientist's Toolkit: Research Reagent Solutions for PBS & Degradation Studies

Table 2: Essential Materials for PBS Preparation and ASTM F1635-11 Testing

| Item | Function in Protocol | Key Consideration |

|---|---|---|

| Analytical Balance | Precise weighing of salts (mg to g range). | Calibration and precision (±0.1 mg) are critical for molarity accuracy. |

| pH Meter with Electrode | Accurate measurement and adjustment of solution pH. | Requires daily calibration with pH 4.01, 7.00, and 10.01 buffers. |

| Class A Volumetric Flasks | Precise volumetric preparation of solutions. | Ensures final concentration accuracy; use at stated temperature (usually 20°C). |

| Osmometer | Measures solution osmolarity to confirm isotonicity. | Critical for ensuring physiological relevance; requires regular calibration. |

| 0.22 µm PES Membrane Filter | Sterilization of PBS without autoclave-induced precipitation. | Preserves ionic composition; essential for long-term sterile studies. |

| Water Bath or Forced-Air Oven | Maintains immersion medium at 37.0 ± 1.0°C per ASTM. | Forced-air ovens minimize evaporation and condensation issues in sealed vessels. |

| Anhydrous vs. Dihydrate Salts | Source of phosphate and sodium ions. | Must be specified in SOPs; molecular weight differences affect weighing calculations. |

ASTM F1635-11, "Standard Test Method for in vitro Degradation Testing of Hydrolytically Degradable Polymer Resins and Fabricated Forms for Surgical Implants," mandates strict control of incubation conditions to ensure the reproducibility and physiological relevance of biomaterial degradation studies. Central to this standard is the maintenance of a stable temperature of 37°C ± 1°C, simulating human physiological conditions, and rigorous aseptic technique to prevent microbial contamination. Contamination can drastically alter local pH, introduce foreign enzymes, and confound mass loss, molecular weight, and mechanical property measurements, rendering data non-compliant with the standard. This guide details the technical implementation of these two pillars for research aligned with ASTM F1635-11.

The Imperative of Temperature Control (37°C ± 1°C)

Precise temperature maintenance is not merely a convenience; it is a kinetic necessity. Hydrolytic degradation rates of polymers like PLGA, PLLA, and PGA are governed by Arrhenius kinetics, where a 1°C deviation can lead to a measurable change in degradation rate, potentially shifting timepoints for critical data collection.

Table 1: Impact of Temperature Variation on Degradation Kinetics of Common Biomaterials

| Polymer | Degradation Mechanism | Approximate Q₁₀ (Rate change per 10°C) | Estimated Rate Change per +1°C |

|---|---|---|---|

| PLGA (50:50) | Bulk Erosion (Hydrolysis) | ~2.0 | ~7% increase |

| PLLA | Surface/Bulk Erosion | ~1.8 | ~6% increase |

| Collagen | Enzymatic & Hydrolytic | ~1.5 - 2.5 | ~5-9% increase |

| PGA | Bulk Erosion (Hydrolysis) | ~2.2 | ~8% increase |

Note: Q₁₀ is a measure of the rate of change of a biological or chemical system as a consequence of increasing the temperature by 10°C.

Experimental Protocol: Validating Incubator Performance

Objective: To map and verify the temperature uniformity and stability within an incubation chamber used for ASTM F1635-11 testing.

Materials:

- Calibrated, multi-channel data logger with NIST-traceable temperature probes.

- Incubator (forced-air circulation recommended over water-jacketed for uniformity).

- Rack or platform to hold probes in positions simulating sample locations.

Methodology:

- Place a minimum of 9 temperature probes within the incubator: each corner, the center, and midpoints of walls.

- Set the incubator to 37.0°C and allow to equilibrate for 24 hours.

- Record temperature from all probes at 1-minute intervals for a minimum of 24 hours.

- Analysis: Calculate the mean temperature, standard deviation, and the range (max-min) for each probe location and for the entire chamber. The system is compliant if all recorded points fall within 37°C ± 1°C and the spatial variation is less than 0.5°C.

Principles and Execution of Aseptic Technique

Aseptic technique encompasses all procedures to prevent contamination by microorganisms (bacteria, fungi, mycoplasma) and unintended cross-contamination between samples.

Core Aseptic Protocols for Degradation Studies

A. Media/Buffer Preparation & Sterilization:

- Use USP Type I water.

- Filter-sterilize (0.22 µm pore size) all solutions into sterile containers. Autoclaving (121°C, 15 psi, 20 min) is acceptable for phosphate buffers, but may degrade some sensitive polymers or additives.

- Validate sterility by incubating an aliquot of each batch at 37°C for 48 hours prior to use.

B. Sample Handling and Incubation:

- Perform all manipulations in a Class II Biosafety Cabinet (BSC) validated within the last 12 months.

- Use sterile forceps and tools. Sterilize tools by 70% ethanol immersion and flaming, allowing to cool completely before contacting samples.

- Change gloves frequently and disinfect with 70% ethanol.

- Use sterile, single-use containers. If reusing containers, clean rigorously and sterilize by autoclaving.

- Seal containers (e.g., screw-cap vials) tightly to prevent evaporation and contamination ingress.

- Include negative controls (media alone, no sample) in every experiment to monitor for contamination.

C. Regular Monitoring:

- Visually inspect samples weekly for cloudiness, biofilm, or pH indicator color change.

- Periodically plate media samples on LB agar and Sabouraud dextrose agar to test for bacterial and fungal contamination, respectively.

Integrated Experimental Workflow for ASTM F1635-11 Compliance

Diagram Title: ASTM F1635-11 Degradation Study Workflow

Contamination Impact Pathway

Diagram Title: Impact of Contamination on Degradation Data

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents & Materials for Compliant Degradation Studies

| Item | Function in ASTM F1635-11 Context | Critical Specification/Note |

|---|---|---|

| USP Type I Water | Solvent for all immersion media (e.g., PBS). | Must be endotoxin/pyrogen-free to avoid inflammatory confounding. |

| Phosphate Buffered Saline (PBS), pH 7.4 | Standard immersion medium for hydrolytic degradation. | Filter sterilized (0.22 µm); contains antimicrobials (e.g., NaN₃ 0.02%) only if justified and reported. |

| Simulated Body Fluid (SBF) | Alternative immersion medium for bioresorbable ceramics or composites. | Ion concentrations approximate to human blood plasma. Must be filter-sterilized, not autoclaved. |

| 70% Ethanol Solution | Primary disinfectant for BSC surfaces, tools, and gloves. | More effective than higher concentrations at penetrating cell walls. |

| Sterile, Single-Use Specimen Containers | Holds sample and immersion medium. | Polypropylene or chemically inert material; must not adsorb degradation products. |

| Calibrated pH Meter | Weekly monitoring of immersion media pH. | Crucial for detecting microbial contamination (acidic shift) or polymer degradation effects. |

| NIST-Traceable Thermometer | Validating incubator setpoint and uniformity. | Required for the pre-study validation protocol. |

| Sterile Surgical Tools (Forceps, Scissors) | Handling sterile polymer samples. | Must be cleaned and sterilized (autoclave/ethylene oxide) between timepoints to prevent carryover. |

This guide frames time-point strategy within the rigorous framework of ASTM F1635-11, Standard Test Method for *in vitro Degradation Testing of Hydrolytically Degradable Polymer Resins and Fabricated Forms for Surgical Implants*. The standard provides essential guidance but intentionally avoids prescribing a universal sampling schedule. The broader thesis posits that a scientifically-justified time-point strategy is the critical link between standardized methodology and the generation of meaningful, predictive degradation profiles for biomaterials in drug development and implant research. A poorly designed schedule risks missing key transition points, leading to erroneous conclusions about mass loss, molecular weight decline, and release kinetics of incorporated agents.

Core Principles of Time-Point Selection

Effective scheduling transcends arbitrary or calendar-based choices. It is a hypothesis-driven design process based on the material's known properties and the study's objectives.

- Degradation Mechanism: Hydrolytic (bulk vs. surface erosion), enzymatic, oxidative. Bulk-eroding polymers (e.g., PLGA) often exhibit a lag phase followed by rapid loss of properties.

- Initial Material Properties: Starting molecular weight, crystallinity, porosity, and device geometry.

- Expected Kinetic Model: Zero-order, first-order, or more complex models (e.g., autocatalytic).

- Critical Transition Points: The time to onset of mass loss, the point of 50% mass loss, and the complete degradation time are key milestones.

Quantitative Data and Published Sampling Frameworks

Recent literature and standards analysis support a non-linear, staged approach. The table below synthesizes recommendations for a typical 6-12 month study of a bulk-eroding polymer like PLGA.

Table 1: Recommended Staged Time-Point Strategy for Bulk-Eroding Polymers

| Study Phase | Primary Objective | Recommended Frequency | Key Metrics | Rationale |

|---|---|---|---|---|

| Phase 1: Early (0-2 weeks) | Monitor hydration, initial swelling, & early molecular weight (Mw) drop. | Every 24-72 hours | Water uptake, pH of medium, Mw (GPC) | Capture the initial burst release (if drug-loaded) and the onset of hydrolysis. |

| Phase 2: Mid (2-8 weeks) | Track steady-state degradation & property loss. | Weekly to Bi-weekly | Mass loss, Mw, mechanical properties (e.g., tensile strength) | Observe the linear or pseudo-linear phase of degradation before autocatalytic effects dominate. |

| Phase 3: Transition (8-16 weeks) | Identify onset of accelerated mass loss & structural failure. | Every 10-14 days | Mass loss, visual integrity, monomer release (HPLC) | Critical phase where bulk erosion leads to rapid changes. Increased sampling density captures the inflection point. |

| Phase 4: Final (16+ weeks) | Document complete resorption or plateau. | Monthly until endpoint >80% mass loss or plateau | Residual mass, solution analysis | Confirm final degradation products and ensure study captures the endpoint. |

Table 2: Impact of Sampling Density on Data Fidelity (Simulated PLGA Study)

| Time-Point Strategy | Total Time-Points | Inflection Point Detected? | Error in T50 Estimate | Ability to Model Kinetic Order |

|---|---|---|---|---|

| Sparse Linear (Monthly) | 6 | No | > ±4 weeks | Poor (R² < 0.85) |

| Staged, High-Resolution | 15-20 | Yes | < ±1 week | Excellent (R² > 0.95) |

| ASTM F1635-11 Minimum* | 5 | Very Unlikely | Highly Variable | Insufficient |

*ASTM F1635-11 suggests a minimum of five data points for a molecular weight vs. time plot but emphasizes more points are needed to define the curve.

Experimental Protocols for Key Degradation Analyses

Protocol 1: Mass Loss and Water Uptake (Per ASTM F1635-11)

- Sample Preparation: Pre-weigh (Wdry, initial) sterile specimens (n≥5 per time point).

- Immersion: Incubate in phosphate-buffered saline (PBS) at 37°C ± 1°C in sealed containers.

- Sampling: Retrieve specimens per designed schedule. Rinse with deionized water and blot dry.

- Wet Weight: Immediately weigh to obtain wet weight (Wwet).

- Dry Weight: Lyophilize to constant weight (Wdry, final).

- Calculation:

- Mass Loss %: = [(Wdry, initial - Wdry, final) / Wdry, initial] x 100

- Water Uptake %: = [(Wwet - Wdry, final) / Wdry, final] x 100

Protocol 2: Gel Permeation Chromatography (GPC) for Molecular Weight

- Sample Preparation: At each time point, dissolve degraded polymer specimens in appropriate tetrahydrofuran (THF) or chloroform.

- Filtration: Filter through 0.2 µm PTFE filter to remove particulates.

- GPC Analysis: Use HPLC system with refractive index detector and series of polystyrene or PLGA-calibrated columns.

- Data Analysis: Report weight-average molecular weight (Mw), number-average molecular weight (Mn), and polydispersity index (PDI).

Protocol 3: Medium Analysis for Degradation Products

- Medium Collection: At each time point and with each medium change, retain and archive the degradation medium.

- pH Monitoring: Measure pH directly using a calibrated micro-electrode.

- Monomer/Product Analysis: Quantify lactic and glycolic acid monomers (or other relevant products) using High-Performance Liquid Chromatography (HPLC) with UV or charged aerosol detection.

Visualizing the Strategy and Degradation Cascade

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for in vitro Degradation Testing

| Item | Function / Rationale | Example / Specification |

|---|---|---|

| Phosphate Buffered Saline (PBS), pH 7.4 | Simulates physiological ionic strength and pH. Must be sterile to prevent microbial confounding. | 1X, 0.01M phosphate, 0.0027M KCl, 0.137M NaCl. Sterile filtered (0.22 µm). |

| Sodium Azide or Antibiotic/Antimycotic | Biostatic agent to prevent microbial growth during long-term immersion studies. | 0.02% w/v Sodium Azide or 1% v/v Antibiotic-Antimycotic solution. |

| Tetrahydrofuran (THF), HPLC Grade | Primary solvent for GPC analysis of many polyesters (e.g., PLGA, PCL). Must be stabilized. | HPLC grade, stabilized with BHT. Stored over molecular sieves. |

| Polystyrene or PLGA GPC Standards | Calibrates GPC system for accurate molecular weight determination of unknown samples. | Narrow dispersity standards covering expected Mw range (e.g., 1 kDa – 500 kDa). |

| Lactic & Glycolic Acid Standards | Reference standards for quantifying degradation products in medium via HPLC. | USP/PhEur grade for accurate calibration curve generation. |

| 0.22 µm PTFE Syringe Filters | For sterilizing buffers and filtering polymer solutions prior to GPC injection. | Hydrophobic PTFE prevents adsorption of aqueous analytes. |

| pH Calibration Buffer Solutions | Ensures accuracy of pH monitoring, critical for detecting autocatalytic effects. | Certified buffers at pH 4.01, 7.00, and 10.01 at 25°C. |

| Inert Sealed Vials/Containers | Prevents evaporation of medium and contamination during incubation. | Polypropylene containers with silicone gasket seals. |

Within the rigorous framework of biomaterial degradation testing, as standardized by ASTM F1635-11, "Standard Test Method for in vitro Degradation Testing of Hydrolytically Degradable Polymer Resins and Fabricated Forms for Surgical Implants," the processes of sample retrieval, cleaning, drying, and weighing are critical for generating reliable and reproducible data. This in-depth technical guide details the protocols essential for accurate mass loss determination, a primary metric in assessing the degradation profile of polymeric biomaterials intended for temporary implant applications. Proper execution of these steps minimizes experimental error and ensures alignment with the standard's emphasis on precision and consistency in a simulated physiological environment.

Protocols Within the ASTM F1635-11 Framework

ASTM F1635-11 specifies the use of a phosphate-buffered saline (PBS) solution, often at pH 7.4 and 37°C, to simulate in vivo conditions. The standard mandates periodic retrieval of samples to monitor changes in mass and physical properties over time. The following protocols are designed to comply with and operationalize the standard's requirements.

Sample Retrieval Protocol

Objective: To safely and consistently remove test samples from the degradation medium at predetermined time points without introducing contamination or mechanical damage.

Methodology:

- Preparation: Pre-label sterile, chemically inert containers (e.g., polypropylene) for each sample. Use forceps with non-crushing tips.

- Retrieval: Using the sterile forceps, gently remove each test specimen from its incubation vessel. Allow excess immersion medium to drip off briefly back into the original container.

- Rinse Initiation: Immediately place the sample into a container filled with a pre-warmed (37°C) deionized (DI) water or ultrapure water rinse solution to halt ongoing hydrolytic reactions.

- Documentation: Note any macroscopic changes in sample integrity, shape, or color upon retrieval.

Cleaning Protocol

Objective: To remove all soluble degradation products, residual salts (e.g., PBS crystals), and loosely adherent oligomers or debris from the sample surface without dissolving or damaging the degrading polymer matrix.

Methodology:

- Primary Rinse: Agitate the sample in its first container of DI water for 5 minutes. For fragile samples, gentle orbital shaking is preferred.

- Sequential Rinsing: Transfer the sample to a second, fresh container of DI water for an additional 5-minute rinse. For highly porous materials or those with significant degradation, a third rinse may be necessary.

- Validation: Conduct a conductivity check on the final rinse solution. A reading near that of pure DI water (<5 µS/cm) indicates effective salt removal. If conductivity is high, repeat rinsing until acceptable levels are achieved.

- Special Cases: For samples with persistent adherent deposits, low-power ultrasonic cleaning in DI water for 30-60 seconds may be employed, provided it does not cause fragmentation.

Drying Protocol

Objective: To remove all absorbed and adsorbed water from the sample to achieve a constant, stable dry mass.

Methodology:

- Blotting (Optional): For samples with large surface water droplets, gently blot with a lint-free, low-residue laboratory wipe. Avoid abrasive contact.

- Primary Drying: Place samples in a clean, controlled environment. The most common and standardized method is vacuum drying.

- Equipment: Vacuum oven or desiccator connected to a vacuum pump.

- Conditions: Desiccant (e.g., phosphorus pentoxide, silica gel) must be present. A moderate temperature, typically 37°C to 50°C (below the polymer's glass transition temperature), is used to accelerate water removal without inducing thermal degradation.

- Procedure: Apply a vacuum of ≤100 mTorr (13.3 Pa). Dry until constant mass is achieved.

- Constant Mass Verification: Weigh the sample at 24-hour intervals. Constant mass is defined as a mass change of less than 0.1 mg between two consecutive weighings, separated by at least 24 hours of further drying.

Weighing Protocol

Objective: To obtain an accurate and precise measurement of the sample's dry mass at each time point.

Methodology:

- Equipment: Use a calibrated analytical microbalance with a readability of at least 0.01 mg (0.00001 g). Ensure it is placed on a vibration-isolated table in a draft-free, temperature-stable environment.

- Conditioning: After drying, allow the sample to cool to room temperature in the desiccator to prevent moisture condensation and convection currents from affecting the balance.

- Weighing Procedure:

- Tare the balance with an empty, clean weighing boat or dish.

- Using anti-static tools and gloves, quickly transfer the sample to the boat and record the mass.

- Return the sample to the desiccator and repeat the weighing process. The two measurements should agree within the balance's repeatability specification (±0.02 mg is typical for a 0.01 mg balance). Record the average.

Data Presentation

Table 1: Summary of Critical Protocol Parameters from Current Best Practices

| Protocol Step | Key Parameter | Recommended Specification | Rationale |

|---|---|---|---|

| Cleaning | Rinse Solution | Deionized Water, 18.2 MΩ·cm | Minimizes ionic contamination. |

| Cleaning | Rinse Validation | Final Rinse Conductivity <5 µS/cm | Ensures complete salt removal. |

| Drying | Environment | Vacuum ≤100 mTorr (13.3 Pa) | Lowers boiling point of water for efficient removal. |

| Drying | Temperature | 37°C - 50°C (Polymer dependent) | Accelerates drying without thermal stress. |

| Drying | Constant Mass Criterion | ΔMass < 0.1 mg over 24h | Ensures complete water removal for mass stability. |

| Weighing | Balance Readability | ≤ 0.01 mg (0.00001 g) | Sufficient sensitivity for detecting small mass changes. |

| Weighing | Environmental Control | Draft shield, vibration isolation, stable temperature | Eliminates sources of weighing error. |

Table 2: Example Mass Loss Calculation (Theoretical Data)

| Time Point (Weeks) | Initial Dry Mass (mg) | Retrieved Dry Mass (mg) | Mass Loss (mg) | Percent Mass Loss (%) |

|---|---|---|---|---|

| 0 | 100.00 | 100.00 | 0.00 | 0.00 |

| 4 | 100.00 | 98.45 | 1.55 | 1.55 |

| 12 | 100.00 | 94.32 | 5.68 | 5.68 |

| 24 | 100.00 | 87.11 | 12.89 | 12.89 |

Experimental Workflow Visualization

Title: Sample Processing Workflow for ASTM F1635-11 Mass Loss

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions and Materials

| Item | Function/Description |

|---|---|

| Phosphate-Buffered Saline (PBS), pH 7.4 | The standard immersion medium per ASTM F1635-11, simulating physiological ionic strength and pH to drive hydrolytic degradation. |

| Deionized (DI) Water, 18.2 MΩ·cm | High-purity rinse solution for removing PBS salts and soluble degradation products without introducing contaminants. |

| Vacuum Oven / Desiccator | Provides a controlled, low-humidity, and optionally heated environment for achieving constant dry mass. |

| Phosphorus Pentoxide (P₂O₅) or Silica Gel | Powerful desiccant used within the drying vessel to chemically scavenge residual water vapor. |

| Analytical Microbalance (0.01 mg readability) | Precision instrument required to detect the subtle mass changes indicative of early-stage polymer degradation. |

| Anti-Static Tools & Gloves | Prevents static charge buildup on samples and weighing vessels, which can cause significant weighing errors. |

| Lint-Free, Low-Residue Wipes | For gentle blotting of samples; minimizes particulate contamination. |

| Conductivity Meter | Validates the efficacy of the cleaning protocol by confirming the absence of ionic residues in the final rinse. |

| Chemically Inert Containers (e.g., Polypropylene) | For sample storage and rinsing; prevents leaching or adsorption of materials that could affect mass. |

| Non-Crushing, Sterile Forceps | Allows for safe, aseptic handling of samples to prevent contamination or physical damage. |

The ASTM F1635-11 standard, "Standard Test Method for in vitro Degradation Testing of Hydrolytically Degradable Polymer Resins and Fabricated Forms for Surgical Implants," provides a critical framework for assessing the performance and safety of absorbable polymeric biomaterials. Within this framework, the measurement of specific key analytical endpoints—mass loss, molecular weight change, and visual/morphological alterations—is paramount for understanding degradation kinetics, mechanism, and biocompatibility. This whitepaper provides an in-depth technical guide on executing and interpreting these core measurements, contextualized within the rigorous requirements of ASTM F1635-11 to support robust research and regulatory submissions in drug development and medical device innovation.

Core Analytical Endpoints: Methodologies and Protocols

Mass Loss Measurement

Mass loss is the most direct indicator of polymer degradation, reflecting the erosion of material from the bulk specimen as oligomers and monomers are released into the surrounding medium.

Experimental Protocol (per ASTM F1635-11 Guidance):

- Specimen Preparation: Precisely cut or mold polymer samples to known dimensions (e.g., discs, films). ASTM F1635 recommends a minimum of three replicates per time point.

- Initial Drying & Weighing (M₀): Dry specimens to constant weight in a vacuum desiccator. Record the initial dry mass (M₀) using a high-precision analytical balance (±0.01 mg).

- Immersion in Buffer: Immerse specimens in a controlled degradation medium (typically phosphate-buffered saline, PBS, pH 7.4 ± 0.1) at 37°C ± 1°C. The standard specifies a recommended volume-to-surface area ratio.

- Time-Point Sampling: Remove replicates at predetermined intervals (e.g., 1, 3, 6, 12, 24 weeks).

- Recovery & Final Weighing (Mₜ): Rinse retrieved specimens with deionized water, dry to constant weight under the same initial conditions, and record the final dry mass (Mₜ).

- Calculation: Percent Mass Loss =

[(M₀ - Mₜ) / M₀] * 100.

Table 1: Example Mass Loss Data for Poly(L-lactide) (PLLA) in PBS at 37°C

| Time Point (Weeks) | Average Initial Mass, M₀ (mg) | Average Final Mass, Mₜ (mg) | Mass Loss (%) ± SD |

|---|---|---|---|

| 0 | 50.00 | 50.00 | 0.0 ± 0.0 |

| 12 | 50.10 | 48.95 | 2.3 ± 0.5 |

| 24 | 49.95 | 45.62 | 8.7 ± 0.9 |

| 48 | 50.05 | 38.14 | 23.8 ± 1.3 |

Molecular Weight Analysis via Gel Permeation Chromatography (GPC)

GPC (or Size Exclusion Chromatography, SEC) is the principal method for monitoring the reduction in polymer chain length, which precedes and dictates mass loss.

Detailed GPC Protocol:

- Sample Preparation: At each degradation time point, dissolve a portion of the retrieved (and dried) specimen in an appropriate chromatographic solvent (e.g., tetrahydrofuran, THF, for polyesters). Filter through a 0.2 μm PTFE syringe filter.

- System Calibration: Use narrow dispersity polystyrene (PS) or, ideally, polymethyl methacrylate (PMMA) standards to create a calibration curve of log(Molecular Weight) vs. elution time.

- Chromatography: Inject sample into the GPC system (isocratic pump, columns, refractive index detector). Use a column set suitable for the expected molecular weight range.

- Data Analysis: Calculate the number-average molecular weight (Mₙ), weight-average molecular weight (M𝓌), and dispersity (Đ = M𝓌/Mₙ). Normalized Mₙ is the key metric:

(Mₙ at time t / Mₙ initial) * 100.

Table 2: Example GPC Data for Degrading Poly(D,L-lactide-co-glycolide) (PLGA 50:50)

| Time Point (Weeks) | Mₙ (kDa) ± SD | M𝓌 (kDa) ± SD | Dispersity (Đ) | Normalized Mₙ (%) |

|---|---|---|---|---|

| 0 (Initial) | 95.2 ± 2.1 | 178.5 ± 3.8 | 1.87 | 100.0 |

| 4 | 42.3 ± 1.8 | 65.1 ± 2.5 | 1.54 | 44.4 |

| 8 | 12.5 ± 0.9 | 16.8 ± 1.1 | 1.34 | 13.1 |

| 12 | < 5 kDa | < 8 kDa | - | < 5.3 |

Visual and Morphological Assessment

Qualitative and quantitative imaging provides context for bulk measurements, revealing surface erosion, bulk erosion, cracking, pore formation, and fragmentation.

Protocol for Multi-Scale Imaging:

- Macrophotography: Document specimens against a scale bar at each time point using a standardized lighting setup to track gross changes in size, shape, and opacity.

- Scanning Electron Microscopy (SEM):

- Sample Preparation: Critical-point dry specimens to prevent collapse of hydrated structures. Sputter-coat with a thin layer of gold/palladium for conductivity.

- Imaging: Acquire micrographs at various magnifications (e.g., 100x, 1000x, 5000x) to visualize surface pitting, pore interconnectivity, and internal morphology (from fractured cross-sections).

- Data Recording: Systematically document observations (e.g., "onset of surface porosity at 8 weeks," "significant cracking and fragmentation at 24 weeks").

The Scientist's Toolkit: Essential Research Reagent Solutions