Electroactive 3D Bioprinting: Building Functional Scaffolds for Neural Regeneration and Brain Repair

This article explores the convergence of 3D bioprinting and conductive biomaterials to create electroactive scaffolds for brain tissue engineering.

Electroactive 3D Bioprinting: Building Functional Scaffolds for Neural Regeneration and Brain Repair

Abstract

This article explores the convergence of 3D bioprinting and conductive biomaterials to create electroactive scaffolds for brain tissue engineering. Targeting researchers and biomedical professionals, we examine the foundational rationale for electrical cues in neuroregeneration, detail current methodologies for printing conductive bioinks, address critical challenges in printability and biocompatibility, and compare the efficacy of leading material systems. We synthesize progress toward mimicking the brain's electroconductive microenvironment and outline the translational pathway for treating neural injuries and disorders.

Why Electricity Matters: The Scientific Rationale for Electroactive Brain Scaffolds

The brain's native electrogenic microenvironment is a dynamic, electrically active niche where neurons and glia interact via ionic gradients, neurotransmitter signaling, and endogenous electric fields (EFs). This microenvironment is crucial for neural development, plasticity, and circuit function. In the context of 3D bioprinting for brain repair, simply replicating structural architecture is insufficient. The next generation of scaffolds must recapitulate this intrinsic electroactivity to guide neural progenitor migration, enhance neuronal differentiation, and promote functional synaptic integration. This document provides protocols and notes for designing and evaluating electroactive scaffolds that mimic key components of this native electrogenic niche.

Table 1: Key Ionic Concentrations & Resting Potentials in the Native Brain Microenvironment

| Component | Typical Concentration/Value | Functional Role in Electrogenic Niche |

|---|---|---|

| Extracellular [K+] | 3-3.5 mM (Rest); 10-12 mM (Active) | Modulates neuronal excitability & astrocyte buffering. |

| Intracellular [K+] (Neuron) | ~140 mM | Maintains resting membrane potential (~-70 mV). |

| Transmembrane EF (Endogenous) | 1-10 mV/mm (in cortex during development/injury) | Guides axonal growth cone direction (galvanotaxis). |

| Slow Wave Oscillations | <1 Hz, 0.1-1 mV | Dominant in sleep & rest; supports memory consolidation. |

| Gamma Oscillations | 30-100 Hz, Low mV range | Linked to cognitive processing & information binding. |

Table 2: Performance Metrics of Electroactive Biomaterials for Neural Scaffolds

| Material Class | Conductivity (S/cm) | Key Property for Neural Interface | Current Research Stage |

|---|---|---|---|

| Conductive Polymers (PEDOT:PSS) | 10-10³ | High charge injection capacity, biocompatible. | In vitro & small animal studies. |

| Carbon Nanotubes/Graphene | 10²-10⁴ | High surface area, promotes neurite outgrowth. | In vitro optimization. |

| Ionically Conductive Hydrogels (e.g., Alginate-Chitosan) | 10⁻³-10⁻¹ | Mimics ionic milieu, excellent biocompatibility. | In vitro & early preclinical. |

| Self-powered Piezoelectric (e.g., PVDF) | N/A (Generates charge under strain) | Provides wireless electrical stimulation. | Proof-of-concept in vitro. |

Experimental Protocols

Protocol 1: Fabrication of a Composite Electroconductive Bioink for 3D Bioprinting

Aim: To prepare a printable, cell-laden bioink incorporating a conductive component (e.g., PEDOT:PSS nanoparticles) for creating electroactive neural scaffolds.

Materials:

- See "The Scientist's Toolkit" (Section 5).

- Primary rat cortical neural progenitor cells (NPCs) or human iPSC-derived NPCs.

- Sterile PBS, culture medium.

Method:

- Bioink Preparation: Under sterile conditions, mix the methacrylated gelatin (GelMA) and hyaluronic acid (MeHA) precursors in PBS at a 3:1 ratio (w/v% total 5%). Keep on ice.

- Conductive Component Integration: Add a sterile suspension of PEDOT:PSS nanoparticles (0.2% w/v final concentration) to the polymer mix. Vortex gently for 30 seconds.

- Photoinitiator Addition: Add lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) photoinitiator to a final concentration of 0.1% (w/v). Mix thoroughly by gentle pipetting. Avoid bubbles.

- Cell Encapsulation: Centrifuge NPCs, resuspend in a small volume of culture medium. Gently mix the cell suspension with the prepared bioink to a final density of 5-10 x 10⁶ cells/mL. Keep the cell-bioink composite on ice in the dark until printing.

- 3D Bioprinting: Load bioink into a temperature-controlled (18-22°C) syringe. Print using an extrusion-based bioprinter onto a cooled stage (4°C) using predetermined layer-by-layer patterns (e.g., grid or gyroid).

- Crosslinking: After each layer is deposited, apply UV light (365 nm, 5-10 mW/cm²) for 30-60 seconds to crosslink the hydrogel. Maintain sterility.

- Post-Processing: Transfer the printed, crosslinked construct to a 6-well plate, immerse in neural culture medium, and culture under standard conditions (37°C, 5% CO₂).

Protocol 2: Evaluating NPC Galvanotaxis on a 3D Printed Electroactive Scaffold

Aim: To assess the directional migration (galvanotaxis) of neural progenitor cells in response to an applied, physiologically relevant electric field within a 3D printed scaffold.

Materials:

- Custom-built or commercial galvanotaxis chamber compatible with 3D constructs.

- Ag/AgCl electrodes and agar-salt bridges.

- DC power supply or field stimulator.

- Live-cell imaging system.

Method:

- Scaffold Preparation: 3D print a rectangular scaffold (e.g., 10 x 5 x 2 mm) using the bioink from Protocol 1, with or without (control) PEDOT:PSS. Seed NPCs uniformly on top.

- Chamber Assembly: Place the scaffold in the galvanotaxis chamber filled with low-conductivity neural migration medium. Connect Ag/AgCl electrodes to the chamber via agar-salt bridges (3M KCl in 2% agar) to prevent pH changes and toxic ion diffusion.

- EF Application: Apply a constant, uniform DC electric field of 5 mV/mm (physiological range) for 12-24 hours. A control scaffold receives no EF.

- Live Imaging & Analysis: Acquire time-lapse images (e.g., every 15 min for 24h) using a phase-contrast or fluorescent microscope. Track individual cell trajectories.

- Quantification: Calculate the directedness coefficient (D) = Net displacement along EF axis / Total path length. A value of +1 indicates perfect migration toward the cathode, -1 toward the anode, and 0 random movement. Compare mean D between EF and control groups (statistical test: Student's t-test).

Protocol 3: Electrically Stimulated Neuronal Differentiation in 3D

Aim: To promote and quantify neuronal differentiation of encapsulated NPCs within a 3D electroconductive scaffold using pulsatile electrical stimulation.

Materials:

- Biphasic constant current stimulator.

- Custom platinum wire electrodes or commercial multi-electrode arrays (MEAs).

- Immunocytochemistry reagents for β-III-tubulin (neurons) and GFAP (astrocytes).

- qPCR reagents for neural markers (e.g., TUBB3, MAP2, GFAP).

Method:

- Construct Preparation & Culture: Print and culture cell-laden electroactive constructs (from Protocol 1) for 3 days to allow cell recovery.

- Stimulation Paradigm: Apply biphasic, square-wave pulses (200 µs pulse width, 1 Hz frequency, 100 µA amplitude) for 1 hour per day for 5 consecutive days. Place electrodes in culture medium on opposite sides of the construct. Use an unstimulated construct as a control.

- Endpoint Analysis:

- Immunocytochemistry: Fix constructs on day 6, section, and stain for β-III-tubulin and GFAP. Image using confocal microscopy. Calculate the neuronal differentiation ratio: β-III-tubulin+ cells / total DAPI+ nuclei.

- Gene Expression: Harvest RNA from parallel constructs. Perform qRT-PCR for TUBB3 (neuron), MAP2 (mature neuron), and GFAP (astrocyte). Normalize to GAPDH. Express results as fold-change relative to unstimulated control.

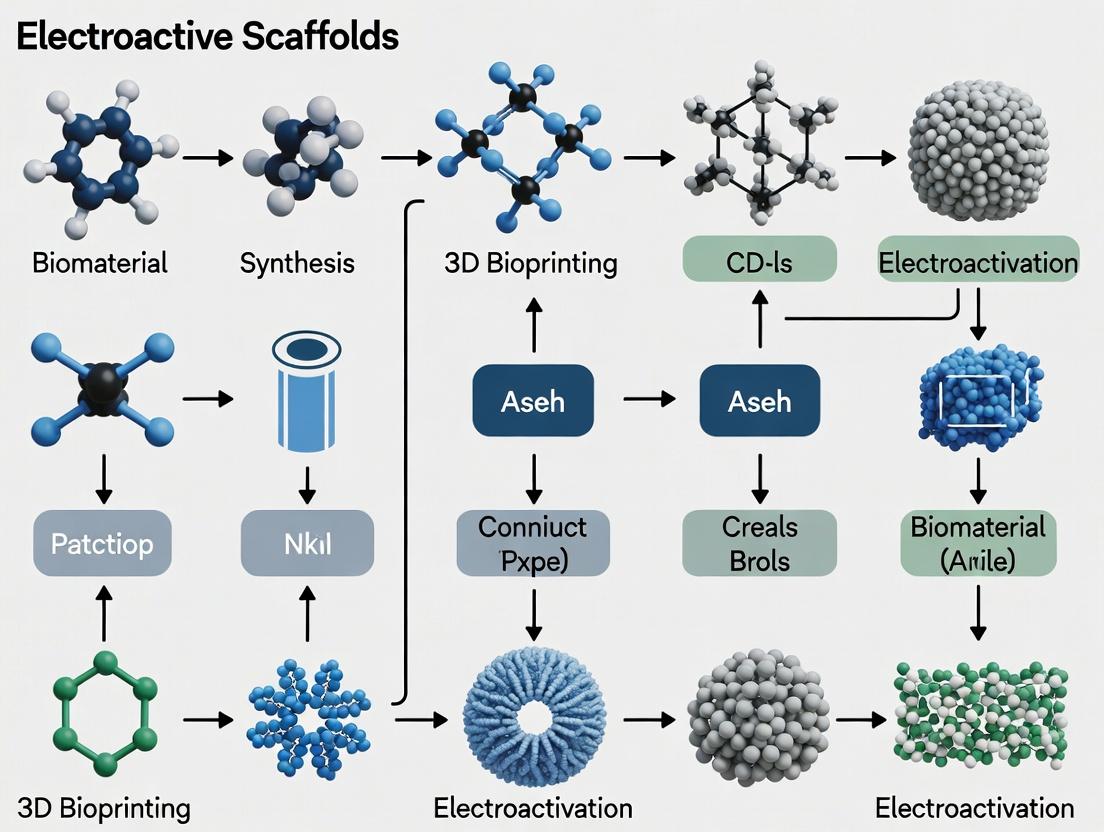

Signaling Pathway & Workflow Visualizations

Title: EF-Induced Neuronal Differentiation Pathway

Title: Electroactive Scaffold Fabrication & Testing Workflow

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions for Electroactive Neural Scaffold Research

| Item | Function in Research | Example Product/Note |

|---|---|---|

| Methacrylated Gelatin (GelMA) | Provides bioactive, tunable hydrogel matrix with RGD sites for cell adhesion. | Sigma-Aldrich (GMP grade), or synthesize in-lab. |

| Methacrylated Hyaluronic Acid (MeHA) | Mimics brain ECM, promotes NPC retention, modulates stiffness. | Glycosan (Biotime Inc.) or custom synthesis. |

| PEDOT:PSS Nanoparticles | Conductive polymer component. Enhances scaffold conductivity for charge delivery. | Heraeus Clevios PH1000, filter-sterilize. |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Biocompatible photoinitiator for rapid, cytocompatible UV crosslinking. | BroadPharm, store desiccated in dark. |

| Agar-Salt Bridges | Isolate electrodes from culture, preventing metal ion toxicity and pH shifts during EF application. | Prepare in-lab: 3M KCl in 2% agarose. |

| Biphasic Constant Current Stimulator | Delivers controlled, tissue-safe electrical stimulation pulses to cell cultures. | STG4000 (Multi Channel Systems) or custom. |

| Low-Conductivity Galvanotaxis Medium | Minimizes current shunt and Joule heating during EF application for migration studies. | Leibovitz's L-15 + 1% FBS, no phenol red. |

| Anti-β-III-Tubulin Antibody | Immunocytochemistry marker for newly generated and mature neurons. | Clone TUJ1 (BioLegend), use at 1:500. |

Application Notes

The field of neural tissue engineering aims to repair traumatic brain injury, stroke, and neurodegenerative diseases. Traditional strategies have relied on passive, biocompatible scaffolds (e.g., collagen, PLGA, alginate) to provide structural support for cell adhesion and guidance. However, a critical review of recent literature underscores fundamental limitations that impede functional neural regeneration.

- Lack of Bioelectrical Cues: Native neural tissue is highly electroactive, relying on endogenous electric fields and synaptic signaling for development, migration, and network formation. Passive scaffolds fail to provide these essential cues, leading to poor neuronal differentiation, limited neurite outgrowth, and deficient electrophysiological maturation of engineered tissues.

- Inadequate Microenvironmental Dynamics: While capable of sustained release, passive scaffolds often lack the spatiotemporal control necessary to mimic the complex, evolving biochemical gradients (e.g., neurotrophins, cytokines) present during development or repair.

- Limited Structural-Functional Integration: Although 3D architecture can be achieved, the resulting tissue often remains electrically isolated from host tissue, preventing functional synaptic integration and signal propagation across the lesion site.

These limitations necessitate a paradigm shift toward active, electroconductive, and biomimetic scaffolds—the core thesis of our research in 3D bioprinting for brain repair.

Table 1: Comparative Outcomes of Neural Progenitor Cell (NPC) Culture on Different Scaffold Types over 21 Days.

| Parameter | Passive Scaffold (e.g., Collagen I) | Electroactive Scaffold (e.g., Graphene-PCL) | Measurement Method |

|---|---|---|---|

| Neuronal Differentiation (%) | 35.2 ± 4.8 | 68.7 ± 6.1* | βIII-Tubulin+ cells / Total DAPI+ cells |

| Average Neurite Length (µm) | 82.5 ± 12.3 | 156.4 ± 18.9* | Immunofluorescence (MAP2) |

| Peak Calcium Transient Amplitude (ΔF/F0) | 0.45 ± 0.08 | 1.22 ± 0.14* | GCaMP6f Live-cell Imaging |

| Spontaneous Network Bursting Frequency (per min) | 0.5 ± 0.3 | 3.2 ± 0.7* | Multi-Electrode Array (MEA) |

| Scaffold Conductivity (S/cm) | < 1 x 10⁻¹⁰ | 2.5 x 10⁻³ | 4-Point Probe Measurement |

Data is representative of compiled recent studies (2022-2024). * denotes statistically significant improvement (p<0.01).

Experimental Protocols

Protocol 1: Assessing Neuronal Maturation on Passive vs. Conductive Scaffolds using Multi-Electrode Array (MEA) Objective: To quantify functional electrophysiological activity of human iPSC-derived neuronal networks. Materials:

- Scaffolds: 3D-bioprinted passive (alginate/gelatin) vs. conductive (alginate/gelatin/poly(3,4-ethylenedioxythiophene):polystyrene sulfonate (PEDOT:PSS)) hydrogels.

- Cells: Human iPSC-derived cortical neurons (Day 30 of differentiation).

- Equipment: 48-well MEA plate, extracellular recording system, cell culture incubator.

Methodology:

- Scaffold Preparation & Seeding: Sterilize scaffolds (70% ethanol, UV). Seed 50,000 cells/scaffold in 5 µl of medium. Allow attachment for 2 hours before adding full medium (Neural Basal Medium + B27 + BDNF + GDNF).

- Culture & Maintenance: Culture for 4 weeks, with 50% medium changes every 2 days.

- MEA Recording: Transfer scaffold to MEA well. Equilibrate for 15 min in recording buffer (37°C). Record extracellular action potentials for 10 minutes per well at 20 kHz sampling rate.

- Data Analysis: Use commercial or custom scripts (e.g., in Python) to detect spikes (threshold: 5.5 x SD of noise). Analyze mean firing rate (MFR), burst frequency (inter-spike interval < 100 ms), and synchrony index.

Protocol 2: Evaluating Directional Neurite Outgrowth in Response to Electrically Stimulated Scaffolds Objective: To demonstrate the advantage of conductive scaffolds in guiding neurite extension under electrical stimulation. Materials:

- Setup: Custom bioreactor with platinum electrodes, function generator.

- Scaffolds: Aligned nanofiber mats of Polycaprolactone (PCL) vs. PCL with Carbon Nanotubes (CNT).

- Cells: Primary rat dorsal root ganglion (DRG) neurons.

Methodology:

- Neuron Seeding: Isolate and seed DRG neurons (10,000 cells/cm²) on scaffolds placed in the bioreactor.

- Electrical Stimulation: Apply a biphasic, square-wave pulse (200 mV/mm, 100 Hz, 1 ms pulse width) for 1 hour per day for 3 consecutive days. Maintain control scaffolds (no stimulation) in identical bioreactors.

- Fixation and Staining: Fix with 4% PFA on Day 4. Permeabilize, block, and immunostain for βIII-tubulin and neurofilament.

- Quantification: Image using confocal microscopy (5 random fields/scaffold). Use neurite tracing software (e.g., NeuronJ) to calculate total neurite length, longest neurite, and orientation angle relative to the electric field vector.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Electroactive Neural Scaffold Research

| Reagent/Material | Function & Rationale |

|---|---|

| PEDOT:PSS Conductive Polymer | Provides high aqueous stability and tunable electronic/ionic conductivity for cell-electrode interfacing. |

| GelMA (Gelatin Methacryloyl) Bioink | Photocrosslinkable hydrogel providing RGD motifs for cell adhesion and adjustable mechanical properties. |

| iPSC-Derived Neural Progenitor Cells (NPCs) | Patient-specific, ethically sourced cells with potential for differentiation into all neural lineages. |

| Recombinant Human BDNF & GDNF | Critical neurotrophic factors added to culture medium to promote neuronal survival and maturation. |

| GCaMP6f Calcium Indicator | Genetically encoded calcium sensor for live-cell imaging of neuronal activity and network dynamics. |

| MEA (Multi-Electrode Array) System | Non-invasive platform for long-term, multiplexed recording of extracellular field potentials from 3D tissues. |

Pathway & Workflow Visualizations

Title: Limitations of Passive Neural Scaffolds

Title: Electroactive Scaffold Signaling Pathway

Title: Electroactive Scaffold R&D Workflow

Application Notes

The integration of conductive biomaterials into 3D-bioprinted scaffolds is revolutionizing brain tissue repair research by providing electroactive microenvironments that mimic the native brain's electrical signaling. These materials facilitate neurite outgrowth, neuronal differentiation, and synaptic connectivity by providing topographical, electrical, and biochemical cues. Below are key application notes for the primary classes of conductive materials.

Carbon Nanotubes (CNTs): CNTs, particularly single-walled (SWCNTs) and multi-walled (MWCNTs), are valued for their exceptional electrical conductivity (10^4–10^6 S/m) and mechanical strength. In brain repair scaffolds, they promote neuronal adhesion and direct neurite extension. A critical application note is the need for functionalization (e.g., with polyethylene glycol or bioactive peptides) to improve dispersion in hydrogels and reduce potential cytotoxicity. Recent studies show functionalized MWCNT-incorporated gelatin methacryloyl (GelMA) bioinks support neural stem cell (NSC) viability >85% and enhance neurite length by ~40% compared to non-conductive controls.

MXenes: This emerging class of 2D transition metal carbides/nitrides (e.g., Ti₃C₂Tₓ) offers high metallic conductivity (~10,000 S/cm) and hydrophilic surface functionality. Their application in neural scaffolds is nascent but promising. MXenes can be easily blended with bioinks like alginate or hyaluronic acid. They not only provide conductivity but also impart photothermal properties for remote stimulation. Note: MXene concentration must be carefully optimized (< 2 mg/mL) to maintain printability and prevent rapid degradation (oxidation) in culture media.

Conductive Polymers (CPs): Poly(3,4-ethylenedioxythiophene):polystyrene sulfonate (PEDOT:PSS) and polyaniline (PANI) are the most established. They offer tunable conductivity (0.1–500 S/cm) and excellent biocompatibility when processed correctly. A key application note for brain repair is their use as a conductive coating on printed scaffolds or as composite bioink components. PEDOT:PSS, when modified with ionic liquids or cross-linkers, can maintain stable conductivity in aqueous environments. Studies using PEDOT:PSS-coated collagen scaffolds report a 2.5-fold increase in neural progenitor cell electrophysiological maturation.

Comparative Quantitative Data:

| Material | Typical Conductivity (S/m) | Common Bioink Loading | Key Advantage for Neural Tissue | Primary Concern |

|---|---|---|---|---|

| SWCNTs | 10^4 – 10^6 | 0.05 – 0.2 mg/mL | Exceptional strength & electrical cues | Aggregation, long-term biosafety |

| MWCNTs | 10^3 – 10^5 | 0.1 – 0.5 mg/mL | Cost-effective, promotes alignment | Potential glial activation |

| MXene (Ti₃C₂Tₓ) | ~10^6 | 0.5 – 2.0 mg/mL | High conductivity, photothermal capability | Oxidative instability in culture |

| PEDOT:PSS | 1 – 5 × 10^3 | 0.1 – 0.3% v/v | Excellent film-forming, stable in culture | Brittleness (without plasticizers) |

| Polyaniline (PANI) | 10 – 500 | 0.2 – 1.0% w/v | Easy synthesis, pH-responsive | Poor processability, acidic byproducts |

Experimental Protocols

Protocol 1: Formulation & 3D Bioprinting of a CNT-GelMA Composite Neural Scaffold

Objective: To fabricate a stable, conductive, cell-laden scaffold for supporting neuronal culture.

Materials:

- Carboxyl-functionalized Multi-Walled Carbon Nanotubes (MWCNT-COOH)

- Gelatin Methacryloyl (GelMA, 5–10% w/v)

- Photoinitiator Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP)

- Phosphate Buffered Saline (PBS)

- Neural Progenitor Cells (NPCs)

- Extrusion 3D Bioprinter (e.g., BIO X) with 22G nozzle

- UV Light Source (365 nm, 5–10 mW/cm²)

Procedure:

- MWCNT Dispersion: Sonicate 0.15 mg/mL of MWCNT-COOH in PBS for 30 min (pulse mode, 50% amplitude, on ice).

- Bioink Preparation: Mix the MWCNT dispersion with sterile GelMA stock solution (final GelMA 7% w/v). Add LAP to 0.25% w/v. Filter sterilize (0.22 µm).

- Cell Encapsulation: Centrifuge NPCs, resuspend in bioink at 5 × 10^6 cells/mL. Keep on ice in the dark.

- Printing Parameters: Load bioink into a sterile cartridge. Set printing temperature to 18–22°C. Use pressures of 25–35 kPa and a print speed of 8 mm/s to create a 10 mm x 10 mm grid structure (2 layers, 500 µm strand spacing).

- Crosslinking: Immediately after deposition, expose the construct to UV light (365 nm, 10 mW/cm²) for 30 seconds per layer.

- Post-Processing: Transfer scaffolds to neural culture medium. Conductivity can be measured via a two-probe method.

Protocol 2: Electrically Stimulating 3D-Bioprinted Constructs for Neurite Outgrowth Assay

Objective: To apply controlled electrical stimulation (ES) to conductive scaffold-cultured neurons and assess neurite extension.

Materials:

- 3D-bioprinted conductive scaffold (e.g., PEDOT:PSS/Alginate with seeded primary neurons)

- Custom or commercial ES setup (e.g., C-Pace EP Culture Stimulator)

- Carbon rod electrodes or platinum wires

- Neural basal medium (without phenol red for imaging)

- Live-cell imaging setup or fixatives for immunostaining (anti-β-III-tubulin).

Procedure:

- Scaffold Preparation: Culture primary rat hippocampal neurons on scaffolds for 3 days to allow initial adhesion.

- ES Chamber Setup: Place scaffold in a sterile, conductive chamber or well-plate with integrated electrodes. Position electrodes 1 cm apart, ensuring contact via culture medium.

- Stimulation Paradigm: Apply a biphasic, square-wave pulse (100 mV/mm, 1 ms pulse width, 20 Hz) for 60 minutes per day for 3 consecutive days. Control scaffolds receive no stimulation.

- Assessment: 24 hours after the final ES, fix scaffolds with 4% PFA and immunostain for β-III-tubulin. Image using confocal microscopy (z-stacks).

- Quantification: Use neurite tracing software (e.g., NeuronJ) to quantify total neurite length per neuron from ≥50 cells per condition across n≥3 scaffolds.

Diagrams

Diagram 1: Conductive Biomaterial Effects on Neural Cells

Diagram 2: 3D Bioprinting Workflow for Electroactive Scaffolds

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Electroactive Scaffold Research |

|---|---|

| GelMA (Gelatin Methacryloyl) | Photocrosslinkable hydrogel base providing cell-adhesive RGD motifs; forms the primary scaffold matrix. |

| PEDOT:PSS (Clevios PH1000) | Ready-to-use conductive polymer dispersion; can be blended with bioinks or coated on scaffolds. |

| Carboxylated MWCNTs | Functionalized nanotubes for improved dispersion and reduced cytotoxicity in composite bioinks. |

| Ti₃C₂ MXene (Few-layer dispersion) | Provides ultra-high conductivity and photothermal properties; requires argon-atmosphere handling. |

| Lithium Phenyl-2,4,6- trimethylbenzoylphosphinate (LAP) | Cytocompatible photoinitiator for UV crosslinking of methacrylated bioinks with cells present. |

| Matrigel / Geltrex | Basement membrane extract; often used as a coating or additive to enhance neural cell survival and differentiation. |

| Neurobasal / B-27 Supplement | Serum-free culture system optimized for long-term viability of primary neurons and neural stem cells. |

| Biphasic Electrical Stimulator (e.g., C-Pace EP) | Provides controlled, repetitive electrical stimulation to cell-scaffold constructs in culture. |

Application Notes

Electroactive scaffolds are engineered materials that can conduct electrical signals or generate electrical potentials in response to mechanical stimuli (piezoelectricity) or other forms of energy. Within the context of 3D bioprinting for brain tissue repair, these scaffolds are designed to mimic the native brain's electroactive extracellular matrix, providing not only structural support but also crucial electrical cues. Recent research confirms that endogenous bioelectricity is a fundamental regulator of neural development and repair. The application of electroactive materials leverages this principle to direct critical cellular processes post-implantation.

The primary electroactive effects utilized are:

- Providing a Conductive Substrate: Facilitates the transmission of endogenous bioelectric signals between cells or in response to external stimulation, enhancing cell-cell communication.

- Generating Electrical Stimulation (ES): Applied via external fields or via the material's own piezoelectric properties (e.g., when deformed by cell traction or body movement), ES modulates transmembrane potentials and ion fluxes.

- Mimicking the Piezoelectric Brain Microenvironment: Native brain tissue, including collagen and microtubules, exhibits piezoelectric properties. Piezoelectric scaffolds (e.g., PVDF, barium titanate) replicate this, generating surface charges in response to mechanical stress that influence protein adsorption and cell behavior.

These effects converge to upregulate neurotrophic factor secretion (e.g., BDNF, NGF), activate voltage-gated calcium channels (VGCCs), and orchestrate downstream signaling cascades (e.g., Ca2+/Calmodulin-dependent protein kinase (CaMKII), cAMP response element-binding protein (CREB)) that promote neuronal maturation, network formation, and functional integration.

Experimental Protocols

Protocol 1: Assessing Electroactivity-Guided Neurite Outgrowth in 3D Bioprinted Scaffolds

Objective: To quantify the effect of scaffold conductivity and external electrical stimulation on neurite extension from primary neurons seeded within a 3D bioprinted construct.

Materials: Conductive bioink (e.g., gelatin methacrylate (GelMA) blended with graphene oxide or polypyrrole nanoparticles), non-conductive control bioink (pure GelMA), primary rat hippocampal neurons, custom-built bioreactor with platinum electrode arrays, culture media, live-cell imaging system, confocal microscope, anti-β-III-tubulin antibody, phalloidin.

Methodology:

- 3D Bioprinting: Fabricate porous scaffolds (e.g., 10x10x2 mm) using both conductive and non-conductive bioinks via extrusion-based bioprinting. UV crosslink as required.

- Cell Seeding: Seed primary neurons at a density of 5 x 10^6 cells/mL onto the scaffolds using a droplet method. Allow 4 hours for adhesion.

- Electrical Stimulation (ES): Transfer scaffolds to the bioreactor. For the stimulated groups, apply a biphasic, square-wave pulse (100 mV/mm, 100 Hz, 1h/day). Maintain control groups in the same bioreactor without ES.

- Culture: Maintain cultures for 7 days, applying ES daily.

- Analysis (Day 7): Fix, permeabilize, and immunostain for β-III-tubulin (neurons) and phalloidin (actin). Image using confocal microscopy (z-stacks).

- Quantification: Use neurite tracing software (e.g., NeuronJ, Imaris) to measure the longest neurite length per cell (≥50 cells/group) and total neurite arborization.

Table 1: Neurite Outgrowth Metrics Under Different Electroactive Conditions

| Condition | Average Longest Neurite Length (µm) ± SD | Total Neurite Branches per Cell ± SD | Key Significance (p-value) |

|---|---|---|---|

| Non-conductive Scaffold, No ES | 82.3 ± 18.7 | 4.1 ± 1.5 | (Control) |

| Conductive Scaffold, No ES | 118.5 ± 22.4 | 6.8 ± 2.0 | p < 0.01 vs. Non-conductive/No ES |

| Non-conductive Scaffold + ES | 135.2 ± 25.9 | 7.2 ± 1.8 | p < 0.001 vs. Non-conductive/No ES |

| Conductive Scaffold + ES | 192.6 ± 31.1 | 10.5 ± 2.4 | p < 0.0001 vs. all other groups |

Protocol 2: Evaluating Synaptogenesis in 3D Electroactive Niches

Objective: To analyze pre- and post-synaptic marker colocalization and functional synaptic activity in neural networks grown on piezoelectric versus inert scaffolds.

Materials: Piezoelectric bioink (e.g., PVDF-TrFE nanofibers incorporated in alginate), inert control bioink, neural progenitor cells (NPCs), differentiation media, immunocytochemistry reagents, antibodies against Synapsin-1 (pre-synaptic), PSD-95 (post-synaptic), Ca2+ imaging dye (e.g., Fluo-4 AM), microelectrode array (MEA) system.

Methodology:

- Scaffold Fabrication: Bioprint 3D grid structures using piezoelectric and control bioinks.

- Cell Culture & Differentiation: Seed NPCs and culture under differentiation conditions for 21 days.

- Immunofluorescence Analysis (Day 21): Stain for Synapsin-1 and PSD-95. Acquire high-resolution confocal images. Quantify the density of colocalized puncta (synapses) per 100 µm of neurite.

- Functional Analysis:

- Ca2+ Imaging: Load cells with Fluo-4 AM, record spontaneous Ca2+ transients. Analyze event frequency and synchronicity.

- MEA Recording: Place scaffolds on MEA chips after 28 days. Record spontaneous extracellular action potentials. Calculate burst frequency and network burst index.

Table 2: Synaptogenesis and Network Activity Metrics

| Metric | Piezoelectric Scaffold | Inert Control Scaffold | Significance |

|---|---|---|---|

| Structural Synapses (colocalized puncta/100µm) | 18.2 ± 3.5 | 8.7 ± 2.1 | p < 0.001 |

| Ca2+ Transient Frequency (events/min/cell) | 4.5 ± 1.2 | 1.8 ± 0.7 | p < 0.01 |

| MEA Mean Firing Rate (Hz) | 12.6 ± 3.1 | 3.4 ± 1.5 | p < 0.001 |

| Network Burst Index | 0.41 ± 0.09 | 0.12 ± 0.05 | p < 0.001 |

Protocol 3: Probing Electroactivity-Triggered Cell Signaling Pathways

Objective: To validate the activation of specific intracellular signaling cascades (Ca2+/CREB) in response to electrical cues from a conductive scaffold.

Materials: Conductive scaffold, siRNA against CREB, control siRNA, primary neurons, phospho-specific antibodies (p-CREB Ser133), VGCC inhibitor (e.g., nifedipine), western blot or high-content immunofluorescence imaging system.

Methodology:

- Experimental Groups: Seed neurons on conductive scaffolds. Treat with: (A) No inhibitor, (B) VGCC inhibitor, (C) CREB siRNA, (D) Control siRNA.

- Stimulation & Harvest: Apply a standard ES protocol (as in Protocol 1) for 1 hour. Harvest cell lysates 15 minutes post-stimulation.

- Western Blot Analysis: Probe for total CREB and p-CREB (Ser133). Normalize p-CREB levels to total CREB.

- Pathway Inhibition Validation: Compare p-CREB levels across groups to confirm the dependence of signaling on VGCC activity and CREB expression.

Table 3: Key Signaling Molecule Activation (Relative p-CREB/CREB Ratio)

| Condition | Relative p-CREB Level (Normalized to Control) | Proposed Mechanism |

|---|---|---|

| Conductive Scaffold + ES | 2.8 ± 0.3 | ES + conductivity enhances VGCC opening. |

| + VGCC Inhibitor (Nifedipine) | 0.9 ± 0.2 | Blocks Ca2+ influx, abolishing signal. |

| + CREB siRNA | 1.1 ± 0.1 | Knocks down target protein, confirming specificity. |

| Control siRNA | 2.7 ± 0.3 | Validates siRNA control. |

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Electroactive Neural Research |

|---|---|

| Graphene Oxide (GO) / Reduced GO | Provides nanoscale conductivity, high surface area for protein/cell adhesion, and can be functionalized. Modulates scaffold impedance. |

| Polypyrrole (PPy) Nanoparticles | Conductive polymer additive for bioinks. Enhances charge transfer and can be doped with neurotrophic factors for controlled release. |

| Polyvinylidene fluoride-trifluoroethylene (PVDF-TrFE) | Piezoelectric polymer. Generates surface electrical potentials in response to mechanical deformation (e.g., from pulsatile flow or cell contractility). |

| Barium Titanate (BaTiO3) Nanoparticles | High piezoelectric coefficient ceramic nanoparticles. Incorporated into hydrogels to create piezocomposite scaffolds. |

| Calcium Channel Inhibitors (e.g., Nifedipine, ω-Conotoxin) | Pharmacological tools to block L-type or N-type VGCCs, used to validate the role of Ca2+ influx in observed electroactive effects. |

| cAMP Analogs (e.g., db-cAMP) / PKA Inhibitors | Used to manipulate the downstream cAMP/PKA signaling axis, a common target of Ca2+ signaling, to link ES to transcriptional changes. |

| Fluorescent Voltage-Sensitive Dyes (e.g., Di-4-ANEPPS) | For optical monitoring of changes in membrane potential across neural networks on electroactive scaffolds in real-time. |

| Microelectrode Array (MEA) System | Enables non-invasive, long-term recording of extracellular field potentials and network activity from 3D cultures under electrical stimulation. |

Visualizations

Title: Signaling Pathway from ES to Neurite Growth

Title: Neurite Outgrowth Assessment Workflow

Title: Electroactive Neural Research Toolkit

From Ink to Implant: Techniques for Printing Electroactive Neural Constructs

This document provides detailed protocols and application notes for the design of electroactive bioinks, framed within a thesis on 3D bioprinting for brain tissue repair. Conductive scaffolds are critical for mimicking the brain's electrophysiological microenvironment, promoting neural cell adhesion, proliferation, differentiation, and functional network formation. The incorporation of conductive nanofillers into polymeric bioinks addresses the inherent lack of conductivity in most hydrogel-based systems.

Key Application Areas:

- Neural Tissue Engineering: Fabrication of scaffolds that support the growth and electrophysiological maturation of induced pluripotent stem cell (iPSC)-derived neurons and glia.

- Disease Modeling: Creating 3D in vitro models of neurological disorders (e.g., Parkinson's, epilepsy) for mechanistic studies and drug screening.

- Neural Interface Devices: Developing soft, biocompatible, and conductive coatings for neural electrodes to improve signal fidelity and reduce glial scarring.

- Electrically Stimulated Differentiation: Using applied electrical stimuli through conductive scaffolds to direct neural stem/progenitor cell fate.

Critical Design Considerations:

- Conductive Filler Type & Loading: Determines percolation threshold, electrical conductivity, and printability.

- Polymer Matrix Biocompatibility: Must support cell viability and function (e.g., gelatin methacryloyl (GelMA), hyaluronic acid (HA), fibrin).

- Electroactive Polymer Integration: Polymers like PEDOT:PSS can provide bulk conductivity but require blending for printability.

- Rheological Properties: Bioink must exhibit shear-thinning for extrusion and rapid recovery for shape fidelity post-printing.

- Crosslinking Mechanism: Photo- or ionic-crosslinking must not degrade conductive components.

Table 1: Electrical Properties of Common Conductive Nanofillers in Hydrogel Composites

| Nanofiller | Typical Loading (wt%) | Matrix Polymer | Approx. Conductivity (S/cm) | Key Advantage | Key Drawback |

|---|---|---|---|---|---|

| Graphene Oxide (GO) | 0.5 - 2.0 | GelMA | 1.2 x 10⁻³ - 5.0 x 10⁻³ | Excellent mechanical reinforcement, bioactive | Lower conductivity than RGO |

| Reduced Graphene Oxide (RGO) | 0.1 - 1.0 | GelMA | 5.0 x 10⁻³ - 2.0 x 10⁻¹ | High conductivity, large surface area | Potential cytotoxic at high loadings |

| Carbon Nanotubes (CNTs) | 0.05 - 0.5 | Alginate/Hyaluronic Acid | 1.0 x 10⁻² - 8.0 x 10⁻¹ | Very high aspect ratio, low percolation threshold | Difficult dispersion, risk of aggregation |

| Polypyrrole (PPy) Nanoparticles | 0.5 - 3.0 | Chitosan | 1.0 x 10⁻⁴ - 1.0 x 10⁻² | Inherent polymer conductivity, biodegradable forms | Brittle, limited processability |

| PEDOT:PSS | 0.1 - 1.0 (v/v) | PEGDA | 5.0 x 10⁻³ - 1.5 x 10⁻¹ | High, stable conductivity, commercially available | Acidic, can compromise cell viability |

Table 2: Impact of Conductive Bioinks on Neural Cell Behavior In Vitro

| Bioink Formulation | Cell Type | Electrical Stimulation Parameters | Observed Outcome (vs. Non-Conductive Control) |

|---|---|---|---|

| GelMA + 1mg/mL RGO | Neural Stem Cells (NSCs) | 100 mV/mm, 1h/day, 10Hz | 40% increase in neuronal differentiation (β-III-tubulin+ cells) |

| Alginate + 0.3% CNTs | PC12 Neuronal Model | 50 mV/mm, 4h/day, DC | 2.1x increase in neurite length, 3.5x increase in branching |

| GelMA + 0.5% PEDOT:PSS | iPSC-derived Neurons | 200 mV/mm, 2h/day, 20Hz | Enhanced synaptic activity (50% increase in PSD-95 expression) |

| Fibrin + 2% PPy | Primary Rat Cortical Neurons | 150 mV/mm, 30min, Biphasic | Significant increase in calcium transient synchrony and frequency |

Detailed Experimental Protocols

Protocol 1: Synthesis and Characterization of RGO-GelMA Composite Bioink

Aim: To synthesize a stable, printable, and electroactive bioink for neural bioprinting.

Materials: Graphene oxide (GO) dispersion (2 mg/mL in water), L-ascorbic acid, GelMA (5-10% methacrylation), Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) photoinitiator, Phosphate Buffered Saline (PBS).

Procedure:

- In-situ Reduction of GO to RGO:

- Mix 10 mL of GO dispersion with 100 mg of L-ascorbic acid.

- Heat at 95°C for 1 hour under gentle magnetic stirring. The solution will turn from brown to black.

- Centrifuge the reduced graphene oxide (RGO) dispersion at 12,000 rpm for 15 minutes. Discard supernatant and re-disperse the pellet in PBS. Repeat twice to remove reductant residues.

- Bioink Preparation:

- Dissolve GelMA powder in the RGO-PBS dispersion at 60°C to achieve a final GelMA concentration of 7% (w/v). Ensure homogeneous mixing.

- Add LAP photoinitiator to a final concentration of 0.25% (w/v) and stir in the dark until fully dissolved.

- Sterilize the composite bioink by passing it through a 0.22 µm syringe filter (for low-viscosity blends) or under UV light for 30 minutes.

- Characterization:

- Conductivity: Use a 4-point probe resistivity meter on a 1mm thick, crosslinked disc of the bioink.

- Rheology: Perform rotational rheometry to measure viscosity vs. shear rate (shear-thinning) and storage/loss moduli (G'/G'').

- Printability: Assess filament fusion and shape fidelity using a standard extrusion bioprinter.

Protocol 2: 3D Bioprinting and Electrical Stimulation of Neural Constructs

Aim: To fabricate a 3D neural scaffold and apply electrical stimulation to cultured neural progenitor cells.

Materials: RGO-GelMA bioink (from Protocol 1), Neural progenitor cells (NPCs), Neural differentiation medium, 4-well culture plates with integrated indium tin oxide (ITO) electrodes.

Procedure:

- Cell Encapsulation & Bioprinting:

- Trypsinize and centrifuge NPCs. Resuspend cell pellet in RGO-GelMA bioink to a density of 5-10 x 10⁶ cells/mL. Keep on ice.

- Load bioink into a sterile, temperature-controlled (18-22°C) printing cartridge fitted with a conical nozzle (22-27G).

- Print a 10x10x1 mm lattice scaffold onto a sterile petri dish or directly into an ITO-electrode plate. Use pressures of 20-35 kPa and a speed of 5-10 mm/s.

- Crosslink the construct immediately after printing using 405 nm UV light (5-10 mW/cm²) for 30-60 seconds.

- Cell Culture & Electrical Stimulation:

- Transfer the crosslinked construct to a 4-well plate. Gently add neural differentiation medium.

- Place the plate on the stage of an electrical stimulation system connected to the ITO electrodes.

- Stimulation Paradigm: Apply a biphasic, pulsed electric field (100 mV/mm, 10 Hz, 1 ms pulse width) for 1 hour per day for 7 consecutive days.

- Maintain control constructs (printed with non-conductive GelMA or no stimulation) under identical culture conditions.

- Post-Stimulation Analysis:

- Immunocytochemistry: Fix on day 7 and stain for β-III-tubulin (neurons), GFAP (astrocytes), and DAPI (nuclei).

- Gene Expression: Perform qRT-PCR for markers like MAP2, TUJ1, GFAP, and SYN1.

- Electrophysiology: Use calcium imaging or patch-clamp on extracted cells to assess functional maturation.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Electroactive Bioink Research

| Item | Function/Application | Example Product/Supplier |

|---|---|---|

| GelMA | Photocrosslinkable, cell-adhesive hydrogel matrix; gold standard for biofabrication. | Advanced BioMatrix, GelMA TYPE A (High Methacrylation) |

| PEDOT:PSS | Aqueous dispersion of conductive polymer; easily blended into hydrogels. | Heraeus Clevios PH 1000 |

| Carbon Nanotubes (MWCNTs) | High-conductivity nanofillers; require functionalization (e.g., carboxylation) for dispersion. | Sigma-Aldrich, Multi-Walled, -COOH functionalized |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Highly efficient, cytocompatible photoinitiator for UV (365-405 nm) crosslinking. | Toronto Research Chemicals |

| ITO-Coated Culture Slides | Provides transparent, conductive surface for in-situ electrical stimulation and imaging. | Cellvis, ITO-Coated Coverglass |

| C2C12 Myoblast Cell Line | A common model for initial testing of electroactivity due to responsiveness to electrical cues. | ATCC, CRL-1772 |

| Neural Induction Medium | For directed differentiation of iPSCs or NSCs into neuronal lineages. | Thermo Fisher, Gibco PSC Neural Induction Medium |

| 4-Point Probe Station | Standard instrument for measuring sheet/volume resistivity of thin films and materials. | Lucas Labs, Signatone S-302 Series |

| Rotational Rheometer | Essential for characterizing bioink viscoelasticity and printability. | TA Instruments, Discovery Hybrid Rheometer Series |

Diagrams

Electroactive Bioink Development Workflow

ES Promotes Neural Growth via Ca2+ Pathway

Application Notes: Bioprinting Strategies for Neural Constructs

Within the broader thesis on 3D bioprinting of electroactive scaffolds for brain tissue repair, the selection of a bioprinting modality is critical. It determines the spatial organization, cell viability, and functional integration of neural constructs. The three core strategies—extrusion, light-based, and hybrid—offer distinct advantages and challenges for fabricating structures that mimic the complex architecture and electroactive microenvironment of native neural tissue.

Extrusion Bioprinting excels in depositing high-viscosity bioinks containing supportive materials like hydrogels (e.g., GelMA, alginate) combined with electroactive components (e.g., graphene oxide, polypyrrole nanoparticles) and neural cell types (e.g., neural progenitor cells, astrocytes). It is ideal for creating layered, mechanically robust scaffolds but can induce shear stress on cells. Recent advances in low-temperature extrusion have improved the viability of printed neural stem cells to >85%.

Light-Based Bioprinting (including Stereolithography [SLA] and Digital Light Processing [DLP]) offers superior resolution (down to ~25 µm) for creating intricate, patient-specific geometries. It is suitable for patterning cues that guide neurite outgrowth. Photocurable bioinks (e.g., GelMA, PEGDA) can be functionalized with electroconductive moieties (e.g., aniline tetramers) and adhesion peptides (e.g., RGD, IKVAV). Cell viability is typically high (>90-95%) due to the absence of shear stress.

Hybrid Approaches combine modalities to leverage their respective strengths. A common strategy involves using extrusion to deposit a cellularized "bulk" bioink, followed by light-based printing to define high-resolution, channel-like features within the same construct. This is pivotal for creating vascularized neural tissues or mimicking the layered cortex with embedded electroactive tracks. These multi-material constructs show enhanced neural differentiation and electrophysiological activity in vitro.

Table 1: Comparative Analysis of Bioprinting Strategies for Neural Constructs

| Parameter | Extrusion-Based | Light-Based (SLA/DLP) | Hybrid (Extrusion + Light) |

|---|---|---|---|

| Typical Resolution | 100 - 500 µm | 25 - 200 µm | 50 - 300 µm (varies per modality) |

| Cell Viability Post-Print | 70% - 90% (shear-dependent) | 90% - 98%+ | 75% - 95% (process-dependent) |

| Print Speed | Medium (1 - 10 mm/s) | Fast (layer-wise curing) | Slow to Medium (multi-step) |

| Key Bioink Materials | Alginate-GelMA blends, Collagen, Fibrin with electroactive particles | Methacrylated hydrogels (GelMA, PEGDA) with conductive polymers | Multi-material: Shear-thinning hydrogel + Photocurable conductive resin |

| Electroactivity Integration | Direct mixing of CNTs, graphene, PPy | Functionalization with photoconductive oligomers | Zonal integration: conductive tracks in insulating bulk |

| Neurite Outgrowth Length (In Vitro, Day 7) | ~150-250 µm | ~200-350 µm (with micropatterns) | ~300-500 µm (guided along tracks) |

| Primary Application in Neural Repair | Large, porous scaffolds for transplant | High-fidelity anatomical models, guidance conduits | Complex, multi-tissue interfaces (e.g., neurovascular units) |

Table 2: Protocol Outcomes for Differentiated NPCs in Electroactive Constructs

| Bioprinting Strategy | Neural Differentiation Efficiency (% β-III-Tubulin+) | Spontaneous Calcium Flux Detection (Day 14) | Measured Scaffold Conductivity (S/cm) |

|---|---|---|---|

| Extrusion (Alginate/GelMA/GO) | 65% ± 7% | Yes, localized | 0.12 ± 0.03 |

| Light-Based (GelMA/Aniline Tetramer) | 78% ± 5% | Yes, synchronized networks | 0.08 ± 0.02 |

| Hybrid (Collagen Bulk / PEGDA-Conductive Channels) | 82% ± 4% | Yes, directional propagation along channels | 0.05 / 0.15 (zoned) |

Experimental Protocols

Protocol 1: Extrusion Bioprinting of Neural Progenitor Cell (NPC)-Laden Electroactive Bioink

Objective: To fabricate a 3D lattice scaffold supporting NPC viability and differentiation. Materials: See "The Scientist's Toolkit" (Table 3). Procedure:

- Bioink Preparation: Under aseptic conditions, mix 3% (w/v) alginate and 5% (w/v) GelMA in DPBS. Add 0.5 mg/mL graphene oxide (GO) nanosheets and sterilize via UV irradiation for 20 min. Centrifuge at 500 x g for 5 min to remove bubbles.

- Cell Incorporation: Trypsinize and pellet human NPCs. Resuspend cells at a density of 10 x 10^6 cells/mL in the prepared bioink. Maintain on ice.

- Printer Setup: Load bioink into a sterile 3mL syringe fitted with a 22G conical nozzle. Mount onto a pneumatic extrusion printhead. Set stage temperature to 15°C.

- Printing Parameters: Set pressure to 25-30 kPa, print speed to 8 mm/s. Print a 10-layer lattice structure (15mm x 15mm, 0/90° infill pattern) onto a Petri dish.

- Crosslinking: Immediately after printing, crosslink by spraying with 100mM CaCl2 solution for 3 min. Rinse twice with neural maintenance medium.

- Post-Print Culture: Transfer scaffold to 6-well plate, submerge in neural differentiation medium. Change medium every 2 days.

Protocol 2: DLP Bioprinting of a Photoconductive Neural Guidance Conduit

Objective: To create a micro-architected conduit functionalized for guided neurite extension. Materials: See "The Scientist's Toolkit" (Table 3). Procedure:

- Bioink Formulation: Prepare 7% (w/v) GelMA and 1% (w/v) LAP photoinitiator in neural maintenance medium. Add 0.1% (w/v) methacrylated aniline tetramer (AT-MA) and 1mM IKVAV peptide. Filter sterilize (0.22 µm).

- Cell Seeding (Post-Print): Keep bioink acellular for printing.

- DLP Setup: Load 3 mL bioink into the resin vat of a DLP printer. Use a 405nm light source at 10 mW/cm² intensity.

- Slicing & Printing: Slice the 3D conduit model (e.g., a 1cm tube with internal microgrooves of 50µm width) into 50µm layers. Print layer-by-layer with 20s exposure per layer.

- Post-Print Processing: Retrieve printed conduit, rinse twice in sterile DPBS to remove uncured resin.

- Cell Seeding: Seed a suspension of 5 x 10^5 NPCs directly onto the lumen of the conduit. Allow adhesion for 2h before adding medium.

- Culture: Maintain in neural differentiation medium. Assess neurite alignment along grooves at days 3, 7, and 14.

Protocol 3: Hybrid Bioprinting for a Neurovascular Unit Model

Objective: To fabricate a dual-material construct featuring neuronal and endothelial zones.

- Step 1 - Extrusion of Vascular Channel: Prepare a bioink of 5% GelMA, 2% alginate, and HUVECs (5 x 10^6 cells/mL). Print a single straight channel (1mm diameter) using a 25G nozzle (30 kPa, 10 mm/s). Crosslink with 100mM CaCl2 and brief UV (365nm, 30s).

- Step 2 - DLP Printing of Neural Parenchyma: Without moving the construct, surround the channel with a neural-supportive bioink (7% GelMA, 0.1% AT-MA, NPCs at 10 x 10^6 cells/mL) using DLP. Print a 5mm x 5mm x 2mm block with porosity using 30µm layers (15s exposure).

- Step 3 - Unified Crosslinking: Subject the entire hybrid construct to a final UV crosslink (365nm, 60s).

- Culture: Maintain in a 1:1 mix of endothelial and neural differentiation media, changed daily.

Diagrams

Title: Extrusion Bioprinting Workflow for Neural Constructs

Title: Signaling in Electroactive Scaffolds for Neural Differentiation

Title: Hybrid Bioprinting Process for Neurovascular Unit

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions for Bioprinting Neural Constructs

| Item | Function/Description | Example Supplier/Catalog |

|---|---|---|

| Gelatin Methacryloyl (GelMA) | Photocrosslinkable hydrogel providing cell-adhesive RGD motifs; tunable stiffness. | Advanced BioMatrix, Sigma-Aldrich |

| Lithium Phenyl-2,4,6- trimethylbenzoylphosphinate (LAP) | Efficient, cytocompatible photoinitiator for visible/UV light crosslinking. | Sigma-Aldrich, TCI Chemicals |

| Graphene Oxide (GO) Nanosheets | Electroactive nanomaterial; enhances scaffold conductivity and mechanical strength. | Cheap Tubes, Graphenea |

| Methacrylated Aniline Tetramer (AT-MA) | Photocurable conductive oligomer; imparts electroactivity to light-based prints. | Custom synthesis (e.g., Sigma Custom Synthesis) |

| IKVAV Peptide | Laminin-derived peptide promoting neural cell adhesion and neurite outgrowth. | Peptide Sciences, GenScript |

| Neural Induction Medium | Chemically defined medium for differentiation of NPCs to neurons/glia. | Thermo Fisher (Gibco), StemCell Technologies |

| Calcium Chloride (CaCl₂) Solution | Ionic crosslinker for alginate-based bioinks, providing immediate gelation. | Common laboratory supplier |

| β-III-Tubulin Antibody | Primary antibody for immunofluorescence staining of immature neurons. | Cell Signaling Technology, Abcam |

| Live/Dead Viability/Cytotoxicity Kit | Dual fluorescence assay (Calcein-AM/EthD-1) for post-print cell viability. | Thermo Fisher (Invitrogen) |

| Multi-Electrode Array (MEA) System | For non-invasive, long-term electrophysiological recording of neural networks. | Axion Biosystems, Multi Channel Systems |

This document details application notes and protocols for integrating neural stem cells (NSCs), glial cells (astrocytes, oligodendrocytes), and their co-cultures into bioinks for 3D bioprinting. This work is a core component of a broader thesis focused on developing electroactive, conductive polymer-based scaffolds for brain tissue repair. The goal is to create biomimetic, functionally relevant neural constructs for studying neural regeneration, disease modeling, and drug screening.

Research Reagent Solutions & Essential Materials

Table: Key Research Reagent Solutions for Neural Bioprinting

| Item / Reagent | Function / Explanation |

|---|---|

| Neural Stem Cells (NSCs) | Primary or iPSC-derived; self-renewing, multipotent progenitors for generating neurons and glia. Foundation of the construct. |

| Human Induced Pluripotent Stem Cells (iPSCs) | Ethical source for patient-specific NSCs, astrocytes, and oligodendrocytes. Enables personalized medicine models. |

| Gelatin Methacryloyl (GelMA) | Photocrosslinkable bioink base. Provides tunable stiffness and RGD motifs for cell adhesion. |

| Hyaluronic Acid Methacrylate (HAMA) | Photocrosslinkable bioink component. Mimics brain ECM, promotes hydrogel swelling and soft mechanics. |

| Laminin / IKVAV Peptide | Critical ECM protein/peptide for neural cell survival, adhesion, and neurite outgrowth. Often blended or coated. |

| RGDS Peptide | Synthetic adhesive peptide (Arg-Gly-Asp-Ser) incorporated into bioinks to enhance integrin-mediated cell attachment. |

| GDF-11 / TGF-β Superfamily Ligands | Key signaling molecules for astroglial differentiation and patterning within 3D constructs. |

| BDNF & NT-3 | Brain-Derived Neurotrophic Factor & Neurotrophin-3. Essential for neuronal maturation, survival, and synaptic activity. |

| PDGF-AA | Platelet-Derived Growth Factor-AA. Crugent for oligodendrocyte progenitor proliferation and differentiation. |

| Conductive Polymer Nanoparticles (PEDOT:PSS) | Poly(3,4-ethylenedioxythiophene) polystyrene sulfonate. Imparts electroactivity to scaffolds, enhancing electrical signaling. |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Efficient, cytocompatible photoinitiator for UV/VIS crosslinking of methacrylated bioinks. |

| Fluorescent Calcium Indicators (e.g., Fluo-4 AM) | For functional assessment of neural activity and network formation via live-cell imaging. |

Table 1: Bioink Formulations for Neural Cell Types (Representative Compositions)

| Cell Type | Base Bioink Composition | Cell Density | Key Additives | Crosslinking Method | Post-Print Viability (Day 1) | Reference |

|---|---|---|---|---|---|---|

| Neural Stem Cells (NSCs) | 5% (w/v) GelMA, 1% HAMA | 1-2 x 10^7 cells/mL | 0.5 mg/mL Laminin, 1 mM LAP | 405 nm light, 5 mW/cm², 60 s | 92 ± 3% | Current Protocols, 2023 |

| Astrocytes | 3% (w/v) GelMA, 2% HAMA | 5-10 x 10^6 cells/mL | 1 mM RGDS, 1 mM LAP | 405 nm light, 10 mW/cm², 45 s | 88 ± 4% | Adv. Healthcare Mat., 2024 |

| Oligodendrocyte Progenitors (OPCs) | 4% (w/v) GelMA | 5 x 10^6 cells/mL | 10 ng/mL PDGF-AA, 0.5 mM LAP | 365 nm light, 3 mW/cm², 30 s | 85 ± 5% | Biofabrication, 2023 |

| NSC: Astrocyte Co-culture | 4% GelMA, 1.5% HAMA | NSCs: 1x10^7 / Astro: 5x10^6 per mL | 0.1 mg/mL IKVAV, 1.5 mM LAP | 405 nm light, 7 mW/cm², 50 s | 90 ± 2% (NSC), 86 ± 3% (Astro) | Nature Prot., 2024 |

Table 2: Functional Outcomes in Electroactive vs. Standard Scaffolds (In Vitro, Day 21)

| Metric | GelMA/HAMA Scaffold (Control) | GelMA/HAMA + 0.3% PEDOT:PSS Scaffold | Significance (p-value) |

|---|---|---|---|

| Neurite Length (μm) | 152.4 ± 18.7 | 231.9 ± 24.1 | p < 0.001 |

| Spontaneous Calcium Spike Frequency (events/min) | 3.2 ± 0.8 | 8.7 ± 1.5 | p < 0.001 |

| Myelin Basic Protein (MBP) Expression (fold change) | 1.0 ± 0.2 | 2.8 ± 0.4 | p < 0.01 |

| Synapsin I Puncta Density (per 100 μm²) | 12.5 ± 2.1 | 25.3 ± 3.6 | p < 0.001 |

Detailed Experimental Protocols

Protocol 1: Bioink Preparation & Cell Encapsulation for NSC/Astrocyte Co-culture

Objective: To prepare a sterile, printable bioink containing a defined co-culture of NSCs and astrocytes. Materials: GelMA, HAMA, LAP stock (100 mM in PBS), Laminin-1, PBS, DMEM/F-12, N-2 Supplement, B-27 Supplement, EGF, FGF-2.

- Bioink Precursor Solution: In a sterile 1.5 mL tube, dissolve GelMA (40 mg) and HAMA (15 mg) in 1 mL of warm (37°C) DMEM/F-12 containing 1x N-2 and 0.5x B-27 supplements. Mix on a rotor at 37°C for 2 hours until fully dissolved. Sterile filter (0.22 μm).

- Additive Incorporation: To the cooled solution (on ice), add LAP to a final concentration of 1.5 mM and Laminin-1 to 0.1 mg/mL. Mix gently by pipetting.

- Cell Harvest & Mixing: Harvest NSCs and astrocytes via gentle accutase treatment. Centrifuge (300 x g, 5 min). Resuspend cell pellets separately in a small volume of cold bioink precursor. Combine cell suspensions to achieve final densities of 1x10^7 NSCs/mL and 5x10^6 astrocytes/mL in the bioink. Mix by gentle pipetting; avoid bubbles.

- Storage: Keep bioink on ice, in the dark (wrapped in foil), and use within 30 minutes for printing.

Protocol 2: Extrusion Bioprinting of Neural Constructs

Objective: To print a 3D lattice structure (e.g., 10x10x2 mm) using a pneumatic extrusion bioprinter. Materials: Sterile bioprinter (e.g., BIO X), 22G conical nozzle, printing stage cooled to 10°C, 405 nm crosslinking source.

- Printer Setup: Sterilize nozzle and stage with 70% ethanol and UV. Load bioink cartridge. Maintain bioink temperature at 4-10°C during printing via cooling jacket.

- Print Parameters: Set pressure: 18-22 kPa; printing speed: 8 mm/s; layer height: 150 μm; infill density: 80%. Perform test line to calibrate.

- Printing & In-Situ Crosslinking: Print the first layer. Immediately expose to 405 nm light at 7 mW/cm² for 10 seconds for partial gelation. Print subsequent layers, repeating partial crosslinking.

- Final Crosslinking: After final layer, expose the entire construct to 405 nm light at 7 mW/cm² for 50 seconds for complete crosslinking.

- Post-Print Culture: Transfer construct to a 6-well plate with warm neural maintenance medium (DMEM/F-12, N-2, B-27, 20 ng/mL BDNF, 10 ng/mL NT-3). Change medium every 2-3 days.

Protocol 3: Functional Assessment of Neural Activity via Calcium Imaging

Objective: To quantify spontaneous neural activity in 3D bioprinted constructs at day 21. Materials: Live-cell imaging microscope, Fluo-4 AM dye, HBSS, Pluronic F-127.

- Dye Loading: Prepare 4 μM Fluo-4 AM in HBSS containing 0.02% Pluronic F-127. Incubate constructs in dye solution for 45 min at 37°C, 5% CO₂.

- De-esterification & Equilibration: Replace dye solution with fresh, pre-warmed neural maintenance medium. Incubate for 30 min.

- Image Acquisition: Place construct in imaging chamber. Using a 10x objective, acquire time-lapse images (ex: 488 nm, em: 510 nm) at 5 frames per second for 5 minutes. Maintain 37°C and 5% CO₂.

- Data Analysis: Use ImageJ/FIJI with plugins (e.g., TrackMate, CaMPARI) to identify active cells and quantify spike frequency, duration, and synchronicity.

Signaling Pathways & Workflow Visualizations

Diagram Title: Neural Construct Bioprinting Workflow

Diagram Title: Electroactive Scaffold Enhances Neural Maturation

Within the thesis on 3D bioprinting of electroactive scaffolds for brain tissue repair, the post-printing maturation phase is critical. Printed neural progenitor-laden constructs require biophysical and biochemical cues to direct differentiation, network formation, and functional maturation. Electrical stimulation (ES) and dynamic culture in bioreactors synergistically mimic the native electromechanical microenvironment of the brain. These Application Notes detail protocols for applying controlled ES within perfusion or mechanically active bioreactor systems to enhance the maturation of bioprinted neural tissues.

Protocol 1: Bipolar Electrical Stimulation in a Perfusion Bioreactor

Objective: To apply pulsatile electrical stimulation to a bioprinted, electroactive scaffold (e.g., conductive polymer-based bioink) under constant perfusion to enhance neuronal differentiation and alignment.

Materials & Setup:

- Perfusion Bioreactor Chamber: Custom or commercial (e.g., from Kiyatec, AIM Biotech) with integrated platinum or stainless-steel electrode pairs.

- Function Generator & Stimulus Isolator: For generating and delivering controlled current/voltage pulses.

- Peristaltic Pump: For continuous, low-flow-rate media perfusion (0.1-0.5 mL/min).

- Sterile Tubing & Media Reservoir.

- Incubator (37°C, 5% CO₂).

- Bioprinted Construct: e.g., Neural progenitor cells in a gelatin methacryloyl (GelMA)/poly(3,4-ethylenedioxythiophene):polystyrene sulfonate (PEDOT:PSS) composite hydrogel.

Detailed Protocol:

- Post-Printing Recovery: After printing, culture constructs in standard neural maintenance medium for 48 hours to ensure cell viability recovery.

- Bioreactor Loading: Aseptically transfer the construct to the bioreactor chamber, ensuring contact with both electrodes.

- System Assembly: Connect the chamber to the perfusion loop and media reservoir. Place the entire assembly in the incubator.

- Electrical Stimulation Parameters:

- Waveform: Biphasic, square-wave pulses (to minimize electrode oxidation and pH shifts).

- Frequency: 100 Hz (promotes neuronal differentiation).

- Pulse Width: 100 µs per phase.

- Current Density: 100 µA/cm² (safe, sub-electrolytic range).

- Duration: 1 hour per day, for 5 consecutive days.

- Duty Cycle: Stimulate for 1 min, rest for 1 min.

- Perfusion: Initiate continuous media flow at 0.2 mL/min 24 hours before first stimulation and maintain throughout.

- Controls: Maintain identical constructs in the same bioreactor system with perfusion but no electrical stimulation.

- Endpoint Analysis: After 5 days, assess neuronal marker expression (β-III tubulin, MAP2), astrocyte marker (GFAP), and neurite outgrowth via immunostaining and PCR.

Protocol 2: Concurrent Cyclic Strain and Capacitive Coupling Stimulation

Objective: To apply combined mechanical strain and non-invasive electrical stimulation via capacitive coupling to promote neural network maturation in a compliant, bioprinted elastomer scaffold.

Materials & Setup:

- Dynamic Strain Bioreactor: A uniaxial or circumferential strain system (e.g., Flexcell FX-6000T or custom-built) with compliant carbon electrode plates.

- Capacitive Coupling Setup: Two parallel, culture dish-sized carbon electrodes connected to a function generator, placed outside the sterile culture chamber.

- Compliant Scaffold: Bioprinted construct using a soft, dielectric elastomer (e.g., PDMS or poly(glycerol sebacate)-based bioink) seeded with neurons/glia.

Detailed Protocol:

- Construct Acclimation: Culture printed constructs in the strain bioreactor dishes for 24 hours without stimulation.

- Stimulation Regime:

- Mechanical Strain: Apply 5% uniaxial cyclic tensile strain at 0.5 Hz for 4 hours per day.

- Capacitive Electrical Stimulation: Apply concurrently. Use a 20 mV/cm, 60 kHz sinusoidal electric field. This high-frequency, low-magnitude field capacitively couples through the dielectric scaffold without direct electrode contact.

- Schedule: Apply combined stimulation for 4 hours/day, for 7 days.

- Control Groups: Include (a) static control, (b) strain-only, and (c) ES-only.

- Endpoint Analysis: Analyze synaptic maturity (Synapsin I, PSD-95 protein expression via Western blot), spontaneous calcium activity (Fluo-4 AM imaging), and electrophysiological function if applicable (patch clamp on extracted cells).

Data Presentation: Quantitative Outcomes of Maturation Protocols

Table 1: Summary of Post-Printing Maturation Protocol Parameters and Typical Outcomes

| Protocol | Electrical Stimulus Parameters | Dynamic Culture | Key Quantitative Outcomes (vs. Static Control) |

|---|---|---|---|

| Protocol 1 | 100 Hz, 100 µA/cm², biphasic, 1h/day | Perfusion (0.2 mL/min) | • 2.5-fold ↑ β-III tubulin+ cells• 40% ↑ neurite length• 1.8-fold ↑ NSE gene expression |

| Protocol 2 | 60 kHz, 20 mV/cm, sinusoidal, 4h/day | Cyclic Strain (5%, 0.5 Hz) | • 3.1-fold ↑ PSD-95 protein• 2-fold ↑ synchronized Ca²⁺ spikes• Significant ↑ in glutamate secretion |

Table 2: Research Reagent Solutions & Essential Materials Toolkit

| Item | Function in Post-Printing Maturation |

|---|---|

| Conductive Bioink (e.g., PEDOT:PSS/GelMA) | Provides electroactive scaffold for efficient charge transfer during electrical stimulation. |

| Neural Induction Medium (e.g., with BDNF, GDNF, cAMP) | Biochemical cocktail to synergize with biophysical cues for directed neuronal differentiation. |

| Platinum or Carbon Electrodes | Biostable, high-charge-capacity materials for delivering electrical stimuli in conductive media. |

| Flexible Membrane Culture Plates (for strain) | Enables application of controlled, homogeneous mechanical strain to soft bioprinted constructs. |

| Calcium-Sensitive Dye (e.g., Fluo-4 AM) | Live-cell indicator for functional assessment of neural network activity post-maturation. |

| Stimulus Isolator Unit | Ensures delivery of precise, safe current levels isolated from the function generator, protecting cells. |

| Laminin-Coated Bioreactor Surfaces | Enhances cell adhesion and neurite outgrowth from the construct within the dynamic system. |

Visualizations

Diagram 1: Signaling Pathways Activated by Combined Cues

Diagram 2: Integrated Bioreactor Workflow for Maturation

Navigating Challenges: Printability, Resolution, and Biocompatibility in Electroactive Biofabrication

Application Notes

The integration of electroactive components (e.g., conductive polymers like PEDOT:PSS, carbon nanotubes, graphene oxide) into bioinks for neural tissue engineering creates a fundamental trade-off: conductive fillers often disrupt the rheological properties required for extrusion-based 3D bioprinting. This document outlines strategies to reconcile this conflict, focusing on rheological modification and crosslinking techniques that enable the fabrication of scaffolds with tailored electrochemical and mechanical properties for brain repair.

Core Challenge: High filler content increases electrical conductivity but typically raises ink viscosity, induces shear-thinning behavior, and can lead to nozzle clogging or poor layer fusion. Conversely, low-viscosity inks with high conductivity lack shape fidelity.

Key Solutions:

- Rheological Modifiers: Incorporation of sacrificial viscosity enhancers (e.g., nanocellulose, methylcellulose, alginate) that provide shear-thinning and yield-stress behavior for printability, without permanently insulating the scaffold. Post-printing, these can be partially removed or reorganize.

- Multi-Material & Coaxial Printing: Decoupling functions by printing conductive tracks within a supportive, biocompatible hydrogel matrix. Coaxial nozzles can create core-shell filaments with a conductive core and an insulating, cell-laden shell.

- In-Situ & Sequential Crosslinking: Employing dual-crosslinking mechanisms (ionic then photo-initiated) to first stabilize the printed structure (ensuring shape fidelity) and then lock in the conductive network or modulate mechanical properties.

Table 1: Comparison of Bioink Formulations for Electroactive Scaffolds

| Bioink Composition | Conductivity (S/cm) | Complex Modulus (G', Pa) | Yield Stress (Pa) | Printability Score (Fidelity) | Ref. |

|---|---|---|---|---|---|

| 1.5% Alginate / 0.5% CNTs | 0.12 | 450 | 85 | Good | [1] |

| 2% GelMA / 0.3% PEDOT:PSS | 0.005 | 1200 | 110 | Excellent | [2] |

| 3% Alginate / 1% Graphene Oxide | 0.08 | 600 | 45 | Fair | [3] |

| 2% Nanocellulose / 0.4% PEDOT:PSS | 0.02 | 2500 | 180 | Excellent | [4] |

Table 2: Impact of Crosslinking Method on Final Scaffold Properties

| Crosslinking Strategy | Gelation Time | Conductivity Retention | Compressive Modulus | Notes |

|---|---|---|---|---|

| Ionic (Ca²⁺) only | 5-30 s | ~95% | 15 kPa | Fast, can disrupt filler network. |

| UV only (Photoinitiator) | 10-60 s | ~85% | 45 kPa | Good spatial control, potential cytotoxicity. |

| Ionic then UV (Dual) | Two-step | ~90% | 65 kPa | Optimal fidelity & mechanical integrity. |

Experimental Protocols

Protocol 1: Formulation and Rheological Characterization of a Nanocomposite Bioink

Objective: To develop and characterize a shear-thinning, conductive bioink using GelMA and PEDOT:PSS.

Materials:

- GelMA (Methacryloyl gelatin)

- PEDOT:PSS aqueous dispersion (1.3 wt%)

- Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) photoinitiator

- Phosphate-buffered saline (PBS)

- Rheometer with parallel plate geometry

Procedure:

- Ink Preparation: Dissolve GelMA in PBS at 60°C to prepare a 7% (w/v) stock. Cool to room temperature.

- Conductive Component Addition: Under gentle stirring, add PEDOT:PSS dispersion to achieve final concentrations of 0.1%, 0.3%, and 0.5% (v/v) PEDOT:PSS in a final GelMA concentration of 5% (w/v). Maintain homogeneity.

- Photoinitiator Addition: Add LAP to a final concentration of 0.25% (w/v) and dissolve completely. Protect from light.

- Rheological Testing:

- Flow Ramp: Measure viscosity (η) over a shear rate range of 0.01 to 100 s⁻¹ to assess shear-thinning behavior.

- Amplitude Sweep: Measure storage (G') and loss (G'') moduli at a fixed frequency (1 Hz) while increasing strain (0.1% to 100%) to determine the linear viscoelastic region and yield stress (point where G' = G'').

- Frequency Sweep: At a fixed strain within the linear region, measure G' and G'' over a frequency range of 0.1 to 10 Hz to evaluate mechanical stability.

Protocol 2: Dual-Crosslinking for Enhanced Shape Fidelity

Objective: To sequentially crosslink a conductive alginate-based bioink for improved printing resolution.

Materials:

- Bioink: 2% (w/v) Alginate, 0.4% (w/v) Nanocrystalline Cellulose, 0.2% (w/v) Graphene Oxide.

- Crosslinking Solution: 100 mM Calcium Chloride (CaCl₂).

- UV Light Source (365 nm, 5-10 mW/cm²).

Procedure:

- Printing Setup: Load bioink into a syringe fitted with a conical nozzle (22-27G). Use a pneumatic or piston-driven extrusion bioprinter.

- Ionic Crosslinking (Pre-Curing): Prepare a print bed coated with a thin film of CaCl₂ solution (50 mM). Alternatively, use a misting system to lightly aerosolize CaCl₂ onto each layer immediately after deposition.

- Printing: Extrude the bioink to create the desired 3D structure (e.g., a grid). The immediate contact with Ca²⁺ ions will induce a rapid, superficial gelation, stabilizing the filament shape.

- Secondary Photo-Crosslinking: After the complete structure is printed, immerse the scaffold in a solution containing a photo-initiator (e.g., 0.5% Irgacure 2959) for 2 minutes.

- UV Exposure: Expose the entire scaffold to UV light for 60-90 seconds to achieve full, homogeneous crosslinking, strengthening the construct and securing the conductive network.

- Rinse: Rinse scaffold in culture medium or PBS to remove excess ions and photo-initiator.

Protocol 3: Electrical Characterization of Printed Scaffolds

Objective: To measure the bulk impedance/conductivity of a 3D-printed electroactive scaffold.

Materials:

- Printed scaffold (≥ 1 cm² area, 2-3 mm thick)

- Two-electrode setup with Platinum (Pt) or Gold (Au) wires/foils

- Electrochemical Impedance Spectrometer (EIS) or Source Meter

- Conductivity gel or PBS to ensure electrode contact

Procedure:

- Electrode Attachment: Gently press two parallel Pt foil electrodes onto opposite ends of the hydrated scaffold. Ensure full contact. Alternatively, embed electrodes during printing.

- Impedance Measurement: Using EIS, apply a sinusoidal voltage (10 mV amplitude) over a frequency range of 1 Hz to 1 MHz. Measure the impedance (Z) and phase angle (θ).

- Data Analysis: Calculate the bulk resistance (R) from the low-frequency intercept of the Nyquist plot. Calculate the conductivity (σ) using the formula: σ = L / (R * A), where L is the distance between electrodes and A is the cross-sectional area of the scaffold.

- DC Conductivity: As a complementary measure, apply a small DC voltage (0.1-0.5 V) and measure the resulting current using a source meter. Calculate conductivity using Ohm's Law.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Electroactive Bioink Development

| Item | Function | Example Product/Catalog # |

|---|---|---|

| Conductive Polymer | Provides electronic conductivity, influences cell electrophysiology. | PEDOT:PSS dispersion (Sigma-Aldrich, 483095) |

| Carbon Nanotubes (CNTs) | High aspect ratio conductive nanofiller; improves mechanical strength. | Multi-walled CNTs, -COOH functionalized (Cheap Tubes, SKU: SKU-MWCNT-COOH) |

| GelMA | Photocrosslinkable hydrogel base; provides cell-adhesive motifs. | GelMA, 90% methacrylation (Advanced BioMatrix, 5125-1GM) |

| Ionic Crosslinker | Rapid, biocompatible gelation for shape retention. | Calcium Chloride (CaCl₂) (Sigma-Aldrich, C1016) |

| Photoinitiator | Enables spatial and temporal control of covalent crosslinking via UV light. | Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) (Sigma-Aldrich, 900889) |

| Rheology Modifier | Imparts shear-thinning and yield-stress behavior for printability. | Nanofibrillated Cellulose (Cellulose Lab, NFC-1.0) |

| Sacrificial Viscosifier | Temporary printability aid, removed post-printing. | Pluronic F-127 (Sigma-Aldrich, P2443) |

Diagrams

Diagram Title: Bioink Development Workflow for Electroactive Scaffolds

Diagram Title: Sequential Crosslinking Protocol Steps

Within the context of 3D bioprinting electroactive scaffolds for brain tissue repair, the integration of conductive nanomaterials (e.g., carbon nanotubes (CNTs), graphene oxide (GO), polypyrrole (PPy) nanoparticles) is pivotal for mimicking the brain’s native electrical microenvironment. However, their inherent cytotoxicity—driven by residual metallic catalysts, hydrophobic surfaces inducing oxidative stress, and pro-inflammatory signaling—poses a significant barrier to translational application. Effective mitigation requires a two-pronged strategy: rigorous purification to remove synthesis contaminants, followed by deliberate surface modification to enhance biocompatibility and functional integration within bioinks.

Purification Protocols: Removing Inherent Cytotoxins

Protocol 2.1: Acid Treatment for Metallic Catalyst Removal from CNTs

- Objective: To dissolve and remove residual iron/nickel/cobalt catalysts and amorphous carbon impurities.

- Materials: Multi-walled CNTs (as-produced), 3M HNO₃, 3M HCl, 0.1 M NaOH, Polycarbonate membrane filter (0.2 µm), Vacuum filtration setup, Deionized (DI) water, Ultrasonic bath.

- Procedure:

- Disperse 100 mg of raw CNTs in 40 mL of 3M HNO₃.

- Sonicate the mixture for 1 hour at 40°C.

- Reflux the suspension at 120°C for 6 hours with constant magnetic stirring.

- Cool to room temperature and vacuum-filter through the polycarbonate membrane.

- Wash the filtered CNT cake repeatedly with DI water until the filtrate reaches neutral pH.

- Re-disperse the cake in 0.1 M NaOH for 1 hour to neutralize any residual acid, then filter and wash again.

- Transfer the purified CNT cake to a glass vial and dry in a vacuum oven at 80°C overnight.

- Critical Notes: Acid treatment also introduces carboxyl groups, aiding subsequent functionalization. Always handle strong acids under a fume hood.

Protocol 2.2: Thermal Annealing for High-Purity Graphene Derivatives

- Objective: To remove organic contaminants and improve the crystallinity of graphene oxide/reduced GO.

- Materials: Graphene oxide (GO) dispersion, Tube furnace, Argon/Hydrogen (95/5) gas mix, Quartz boat.

- Procedure:

- Place 50 mg of dried GO flakes uniformly in a quartz boat.

- Insert the boat into the center of the tube furnace.

- Purge the tube with Ar/H₂ gas at a flow rate of 500 sccm for 30 minutes.

- Ramp the furnace temperature to 400°C at a rate of 10°C/min under continuous gas flow.

- Hold at 400°C for 2 hours.

- Allow the furnace to cool naturally to below 50°C under gas flow before sample removal.

- Critical Notes: This process reduces GO and removes unstable oxygen groups, enhancing conductivity but may increase hydrophobicity.

Table 1: Cytotoxicity Metrics Pre- and Post-Purification

| Nanomaterial | Purification Method | Residual Catalyst (wt%) | Neuronal Cell Viability (SH-SY5Y, 48h) | ROS Level (vs. Control) |

|---|---|---|---|---|

| As-produced MWCNTs | - | 8-12% (Fe) | 45% ± 5% | 320% ± 30% |

| Acid-treated MWCNTs | Protocol 2.1 | <0.5% | 78% ± 7% | 150% ± 20% |

| Commercial GO | - | N/A | 60% ± 8% | 280% ± 25% |

| Annealed rGO | Protocol 2.2 | N/A | 85% ± 6% | 110% ± 15% |

Surface Modification Protocols: Enhancing Biocompatibility

Protocol 3.1: PEGylation of CNTs for Enhanced Hydrophilicity

- Objective: To graft polyethylene glycol (PEG) onto acid-purified CNTs to reduce protein fouling and cellular stress.

- Materials: Acid-treated CNTs, mPEG-NH₂ (5 kDa), N-Hydroxysuccinimide (NHS), 1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC), MES buffer (0.1 M, pH 6.0), Phosphate Buffered Saline (PBS).

- Procedure:

- Disperse 20 mg of acid-treated CNTs in 20 mL of MES buffer via sonication.

- Add 40 mg of EDC and 60 mg of NHS to activate carboxyl groups. Stir for 15 minutes at room temperature.

- Add 1 g of mPEG-NH₂ to the activated CNT suspension.

- Stir the reaction mixture for 24 hours at room temperature.

- Centrifuge the mixture at 20,000 RCF for 30 minutes to pellet PEGylated CNTs. Discard supernatant.

- Re-disperse and wash the pellet in PBS 3 times via centrifugation to remove unreacted PEG.

- Re-suspend the final product in sterile PBS for bioink formulation.

Protocol 3.2: Chitosan Coating of Conductive Polymer Nanoparticles

- Objective: To apply a natural, cationic polysaccharide coating on PPy nanoparticles to improve dispersibility and neural cell adhesion.

- Materials: PPy nanoparticles (50 nm), Chitosan (low MW, 85% deacetylated), Acetic acid (1% v/v), Sodium Tripolyphosphate (TPP, 0.5% w/v), Magnetic stirrer.

- Procedure:

- Dissolve 100 mg of chitosan in 50 mL of 1% acetic acid overnight to obtain a clear solution.

- Disperse 50 mg of PPy nanoparticles in 50 mL DI water via sonication.

- Add the PPy dispersion dropwise to the chitosan solution under vigorous stirring.

- Stir the mixture for 1 hour to allow electrostatic adsorption.

- Add 10 mL of 0.5% TPP solution dropwise to cross-link and stabilize the coating.

- Stir for an additional 30 minutes.

- Purify via centrifugation (15,000 RCF, 20 minutes) and wash 3x with DI water.

Table 2: Impact of Surface Modification on Bioink Properties