The Muscle Makers

How 3D Printed Elastic Scaffolds Are Engineering New Hope for Tissue Regeneration

The Silent Crisis of Muscle Loss

Imagine a world where severe muscle damage from car accidents, battlefield injuries, or cancer resection isn't permanent. Where lost muscle tissue isn't replaced by stiff, non-functional scar tissue but by living, contracting, functional muscle. This vision is inching closer to reality through a revolutionary marriage of advanced biomaterials and precision 3D printing.

Skeletal muscle, constituting ~40% of human body mass, possesses a limited innate capacity for regeneration after significant trauma or disease. Current treatments, primarily involving muscle flap transfers, are hampered by donor site morbidity and often yield suboptimal functional recovery 3 .

Why Muscle Regeneration is a Monumental Challenge

Dynamic Environment

Scaffolds must provide temporary structural support with mechanical properties matching native muscle (elastic modulus: 30-8000 kPa; failure stress: 70-800 kPa) while degrading at a rate synchronized with new tissue formation 3 7 . Acidic degradation byproducts of some polymers can also trigger harmful inflammation 3 .

The Elastomer Breakthrough: Designed to Mimic Muscle

Conventional polymers fell short. Researchers responded by designing a new generation of segmented thermoplastic polyurethane-urea (TPU) copolymers specifically for muscle regeneration. These aren't your average plastics; they're precision-engineered at the molecular level:

-

Biocompatibility & Wettability

Engineered surfaces offer improved wettability compared to older PCL-based TPUs 1 .

Key Properties Comparison

| Property | Novel TPU Elastomer | PCL | Natural Hydrogels |

|---|---|---|---|

| Elastic Modulus | Low (Matches Muscle) | High (Too Rigid) | Very Low |

| Failure Strain | High (Up to ~60%) | Low/Brittle | High but Weak |

| Degradation Rate | Tunable | Very Slow | Often Too Fast |

| 3D Printability | Excellent | Good | Moderate |

Case Study: Bridging the Gap in a Rat's Leg

The true test of this technology lies in its ability to drive functional regeneration in a living organism. A pivotal experiment demonstrated its potential using a tibialis anterior muscle defect model in rats 1 6 .

Methodology: Precision Implantation

- Scaffold Fabrication: The novel TPU was printed via extrusion-based 3D printing into scaffolds with a defined, porous architecture.

- Cell Seeding (Optional): Some scaffolds were pre-seeded with C2C12 mouse myoblasts.

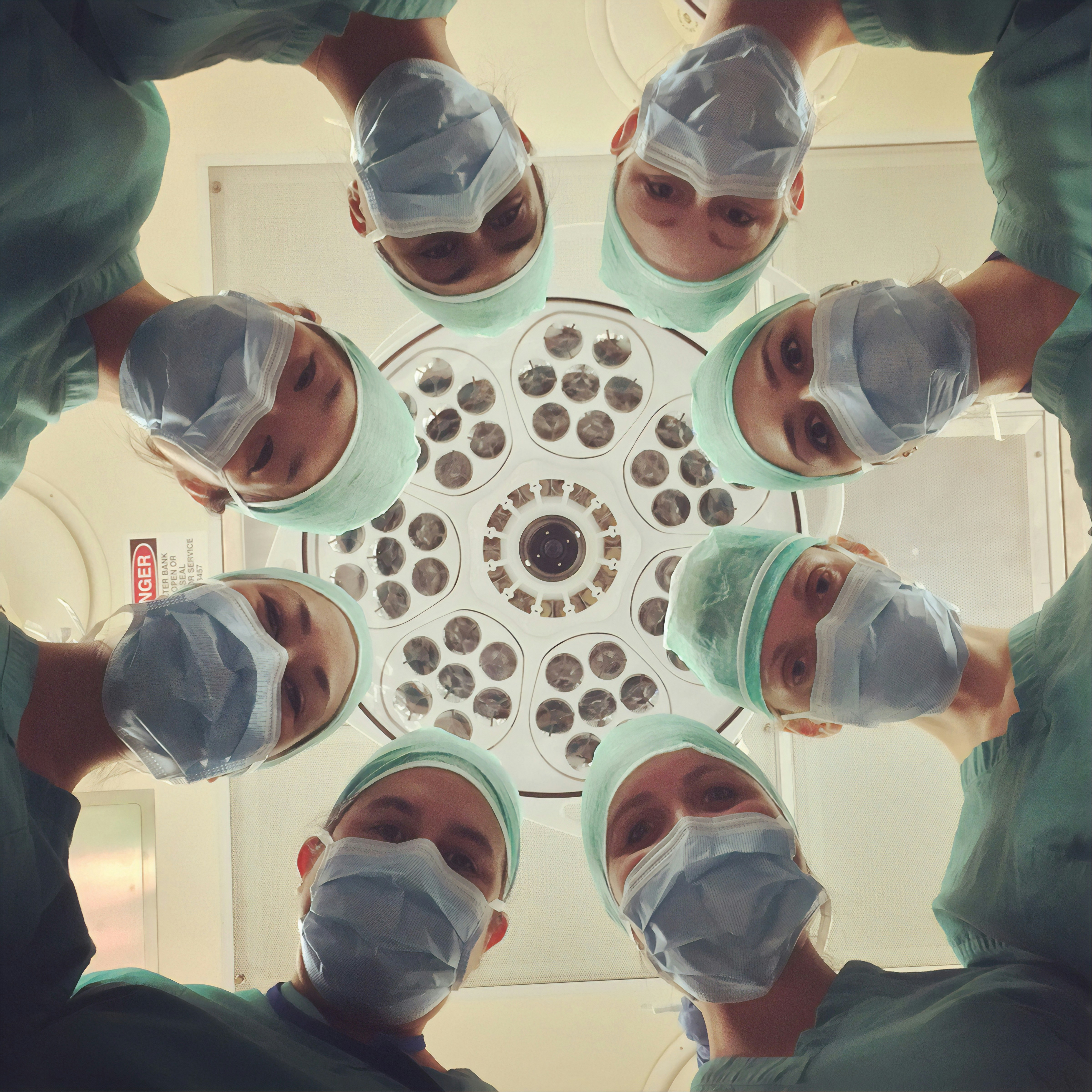

- Surgical Implantation: Scaffolds were implanted into critical-sized defects.

- Post-Op Monitoring & Analysis: Multiple assessment methods were employed.

Results & Analysis: Proof of Function

Key Findings

- Structural Regeneration: Dense, parallel bundles of muscle fibers within TPU scaffolds 1 6 .

- Functional Integration: Robust electrical activity and contractile force generation 1 .

- Vascularization: Extensive new blood vessel formation 1 .

- Controlled Response: Limited activated macrophage response 1 .

Research Toolkit

Beyond the Lab: The Path to Patients

The successful recapitulation of muscle structure and function in the rat model is a foundational leap, but translating this to humans requires overcoming significant hurdles: